Voltage-adjustable piezoelectric power generation device

A piezoelectric power generation and voltage technology, applied in generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problems of reducing service life, energy loss, high-speed rotation, etc. Achieving the effect of wide adaptability and increased range of variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

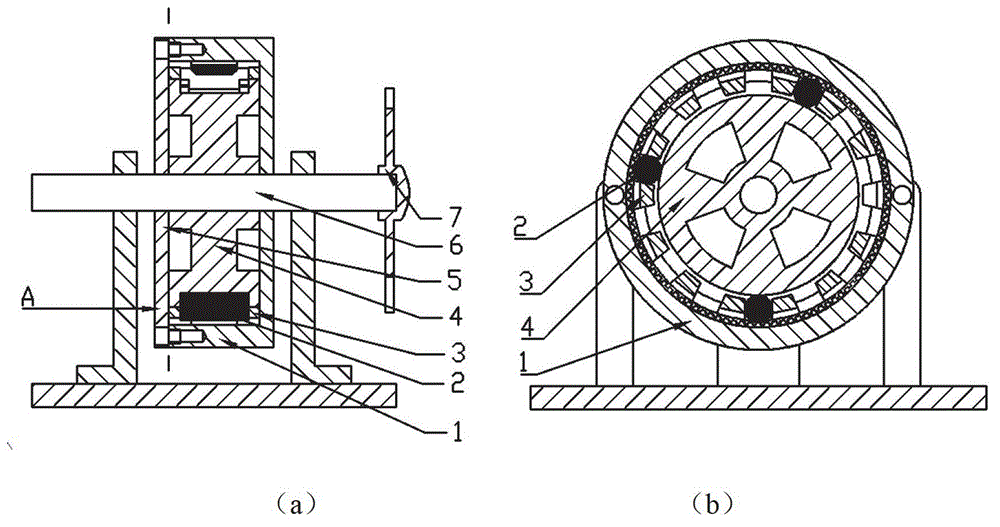

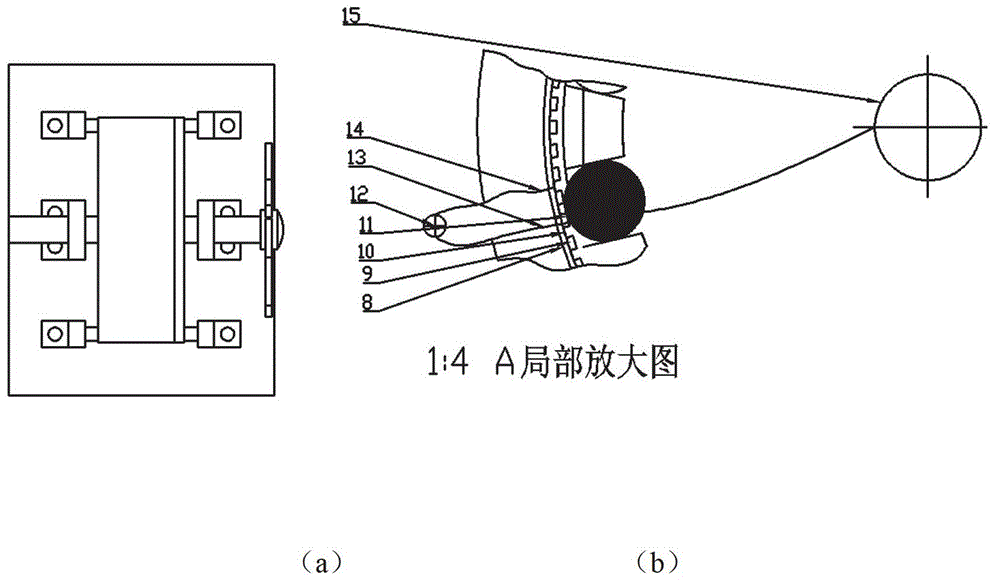

[0010] combine figure 1 ( figure 1 a. figure 1 b) and figure 2 ( figure 2 a. figure 2 b) The voltage-adjustable piezoelectric power generation device of the present invention is composed of a turbine rotor assembly, a piezoelectric coil assembly, and a roller assembly. The turbine rotor assembly includes turbine blades 7 and a rotating shaft 6, and the turbine blades 7 are fixed on the rotating shaft One end of 6 is rotated by the turbine blade 7 to drive the rotating shaft 6 to rotate;

[0011] The roller assembly consists of a rotating disc 4, a roller 2 and a cage 3. The roller 2 is limited by the rotating disc 4 and the cage 3. The roller 2 itself rotates by itself. The rotating disc 4 is fixed in the middle of the rotating shaft 6 and The rotating disk 4 and the cage 3 are clearance fit, so that the cage 3 forms a floating state, and when the rotating shaft 6 rotates, the rotating disk 4, the roller 2 and the cage 3 rotate together around the axis of the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com