Device for controlling the valve control times of an internal combustion engine

A valve control timing and internal combustion engine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of high cost, consumption, and low component strength, and achieve the effects of system power, improved vibration performance, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

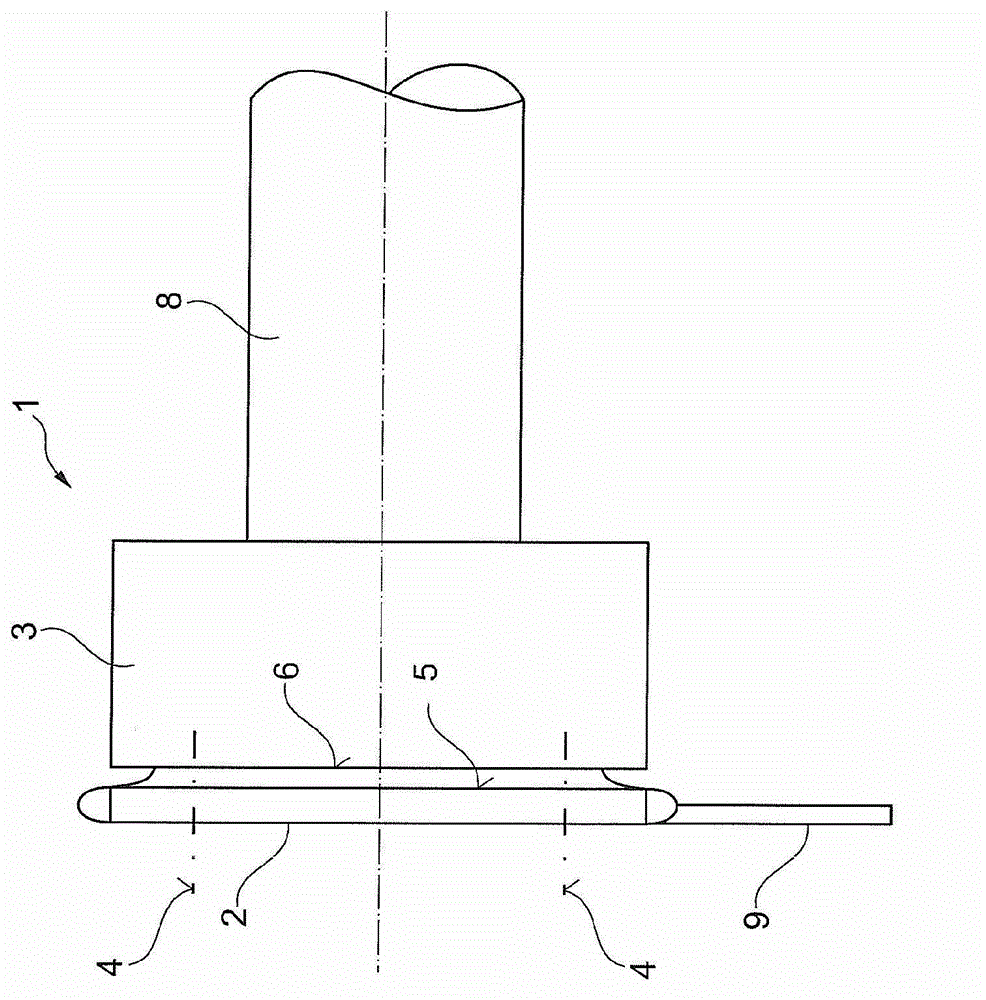

[0025] figure 1 A camshaft adjuster 1 of an internal combustion engine is schematically shown in FIG. The camshaft adjuster 1 is used in a known manner to adjust the inner rotor connected to the camshaft 8 of the internal combustion engine relative to the stator 3 by means of a generally hydraulically actuated (not shown) impeller, so that it is possible between the "advance stop" and the " Hysteresis stop" to adjust. The stator 3 is referred to here as an additional component.

[0026] The camshaft adjuster 1 has a drive element 2 in the form of a toothed pulley driven by the crankshaft of the internal combustion engine by means of a belt 9 . The drive element 2 is screwed to the add-on part 3 using a screw connection 4 for this purpose. The stator 3 is driven by the drive element 2 and rotates about the axis of rotation at the camshaft speed during operation of the internal combustion engine.

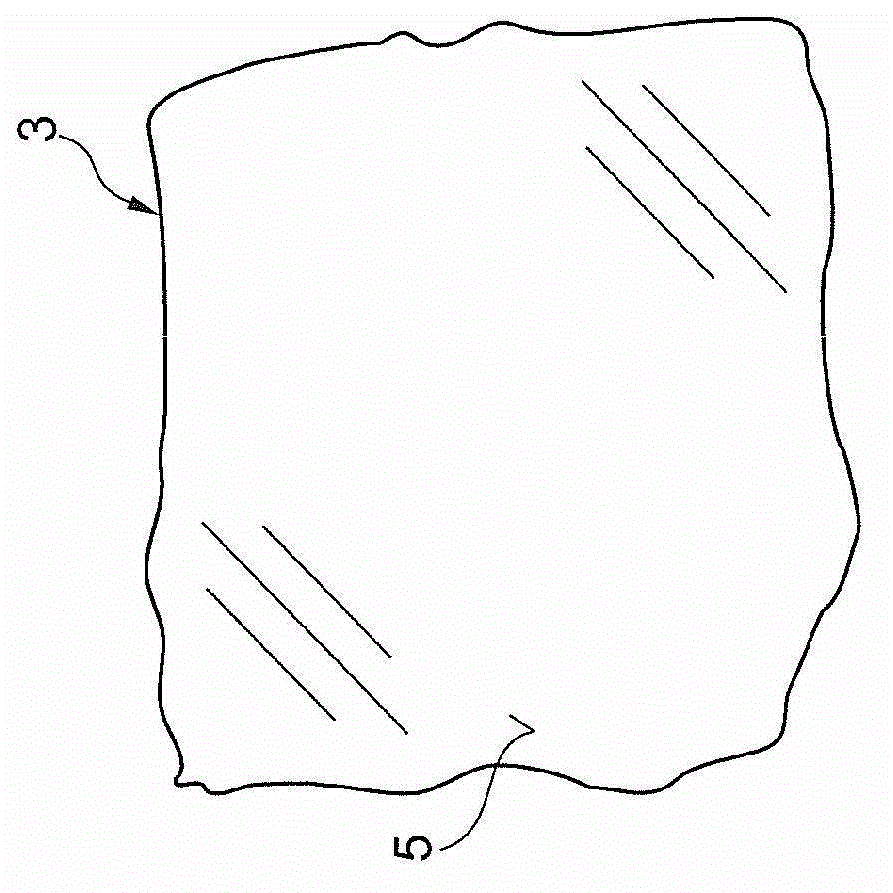

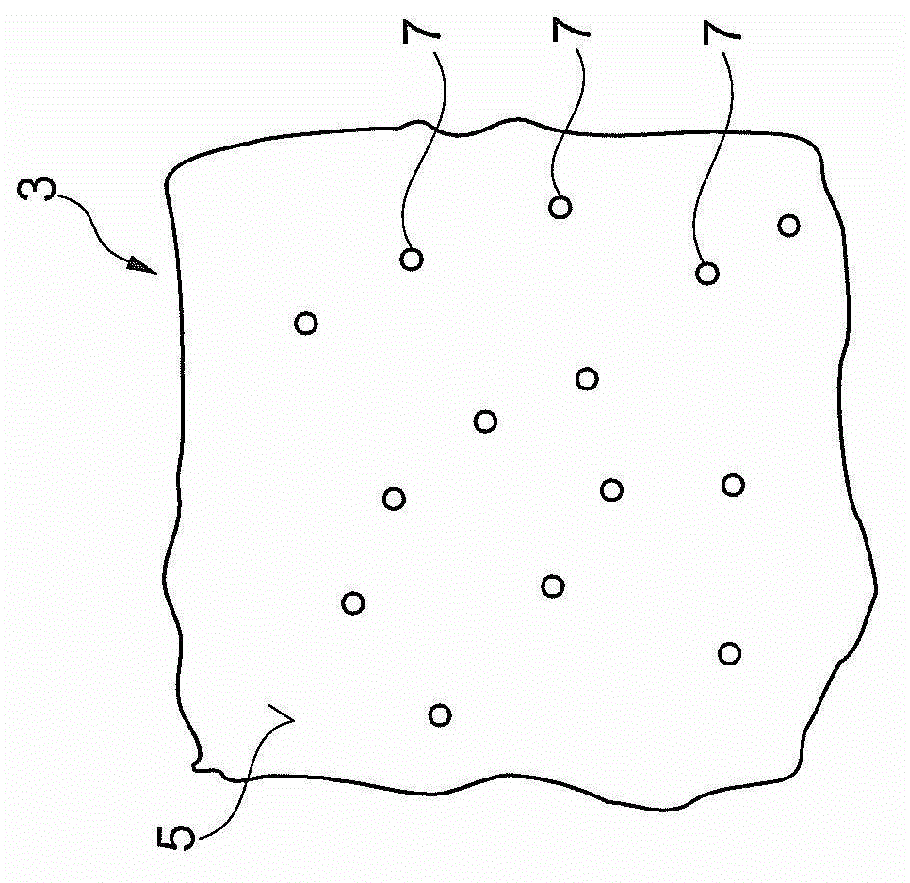

[0027] The additional part 3 has a contact surface 5 for abutting against a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com