High-pressure electrostatic dust collection electric field device of coal-fired unit for generating ozone and simultaneously desulfurizing and denitrating

A coal-fired unit, high-voltage electrostatic technology, applied in the field of high-voltage electrostatic dust removal, can solve problems such as investment in new equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

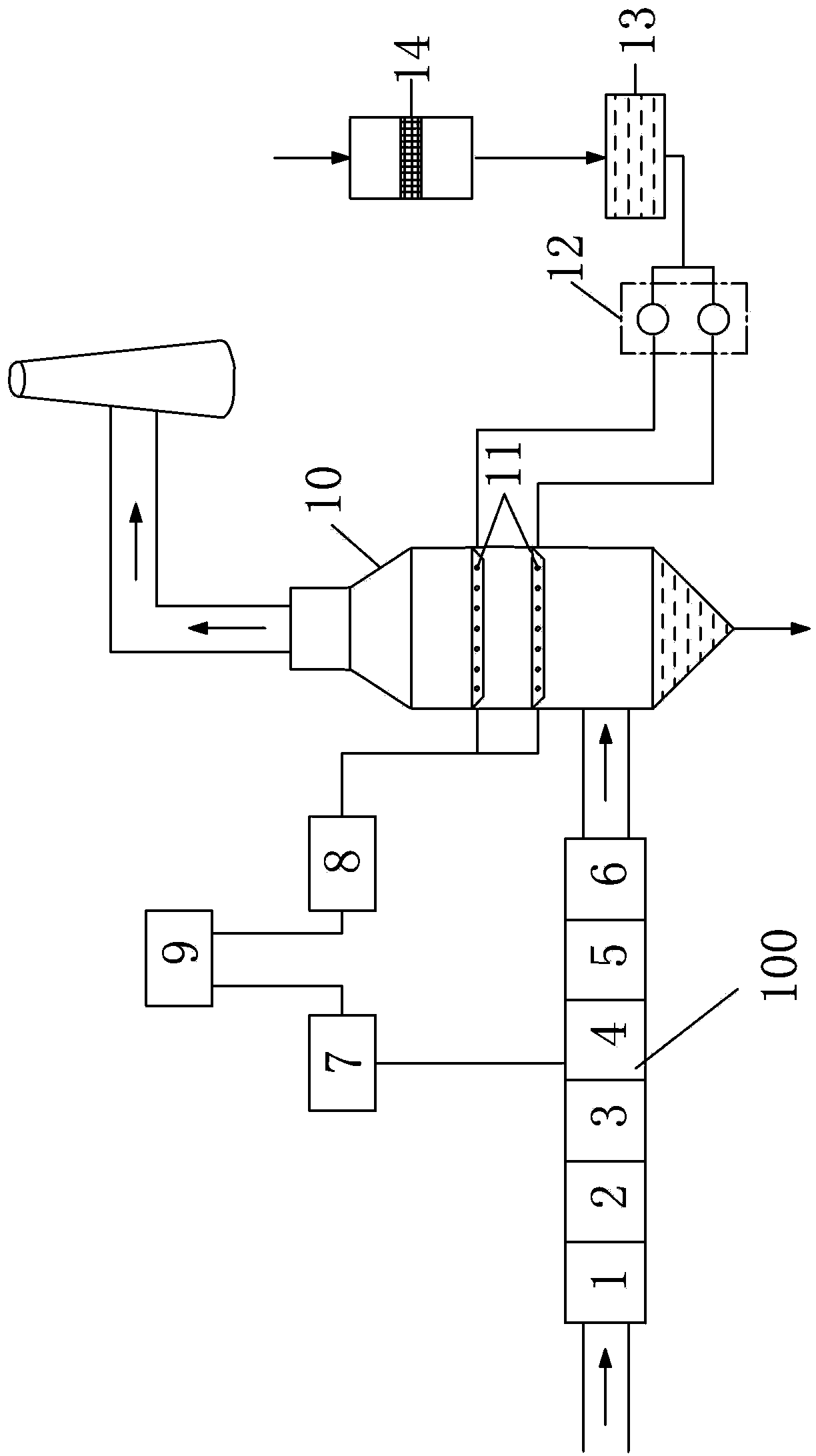

[0027] Examples, see figure 1 As shown, the high-voltage electrostatic precipitating electric field of the coal-fired unit of the present invention generates ozone and simultaneously desulfurization and denitrification device, including:

[0028] An electrostatic dust removal channel 100 composed of a plurality of electric fields connected in sequence. The inlet end of the electrostatic dust removal channel 100 is connected to the dust outlet of the coal-fired unit; in this embodiment, there are six electric fields, namely electric field 1, electric field 2, Electric field 3, electric field 4, electric field 5, electric field 6, the six electric fields are connected in sequence;

[0029] A neutralization tower 10, the lower part of the neutralization tower 10 is provided with an inlet, the inlet is connected with the outlet end of the electrostatic dust removal channel 100, the upper part of the neutralization tower 10 is provided with an outlet, and the outlet is connected with sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com