Grain coating method and grain coating system for diamond wire saws

A diamond wire saw and diamond particle technology, applied in the field of diamond wire saw sand planting methods and systems, can solve the problems of insufficient adhesion, falling off, uneven distribution of diamond particles, etc., to ensure cutting accuracy and cutting efficiency, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

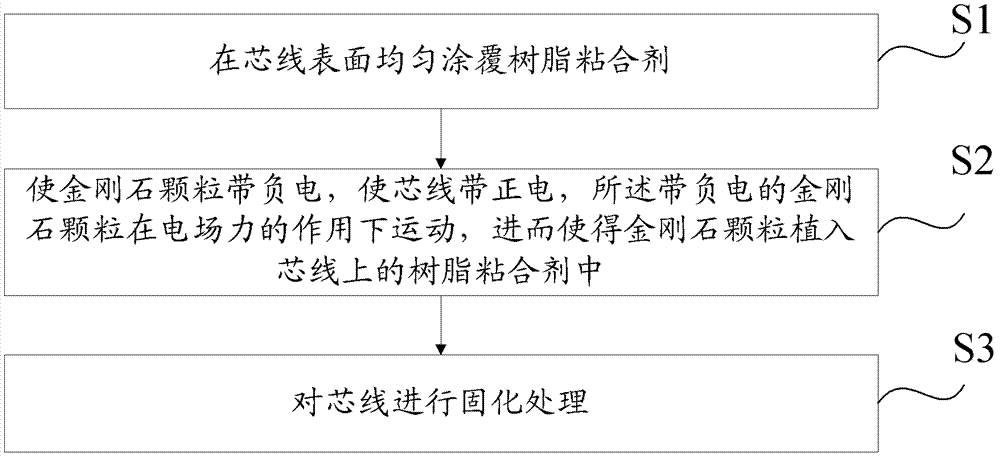

[0041] refer to figure 2 , figure 2 It is a schematic flow chart of a diamond wire saw sand planting method provided by an embodiment of the present invention, and the method includes steps:

[0042] Step S1: uniformly coating the resin adhesive on the surface of the core wire.

[0043] The step S1 specifically includes: passing the core wire through a device containing a resin adhesive at a set speed, and coating a layer of resin adhesive on the surface of the core wire; making the core coated with the resin adhesive The wire passes through a mold with a set aperture to adjust the thickness of the resin adhesive on the surface of the core wire, so that the resin adhesive is evenly coated on the surface of the core wire.

[0044] Wherein, when the core wire passes through the mold with a set aperture, the thickness of the resin adhesive on the surface of the core wire can be adjusted, so that the resin adhesive is evenly distributed on the surface of the core wire, and the...

Embodiment 2

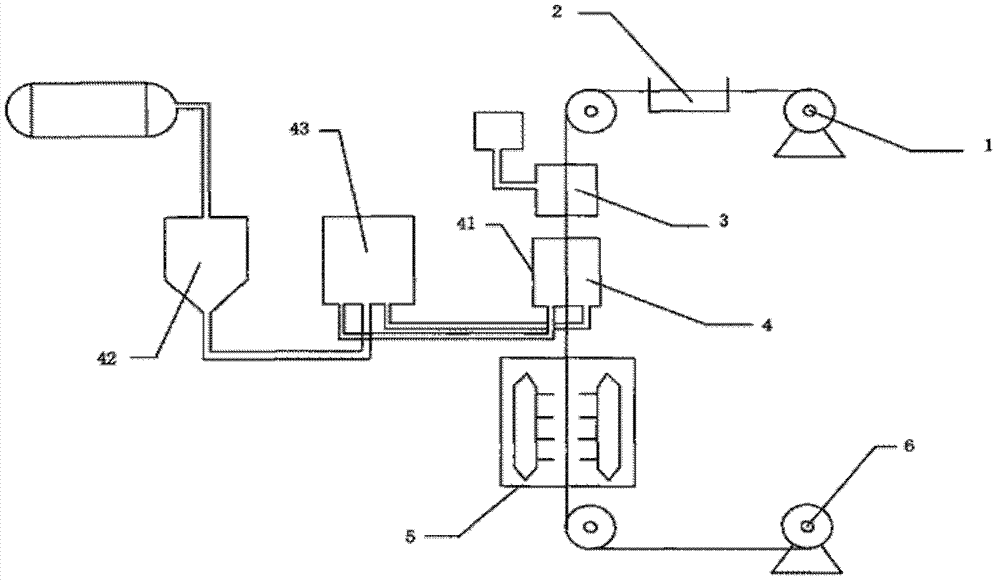

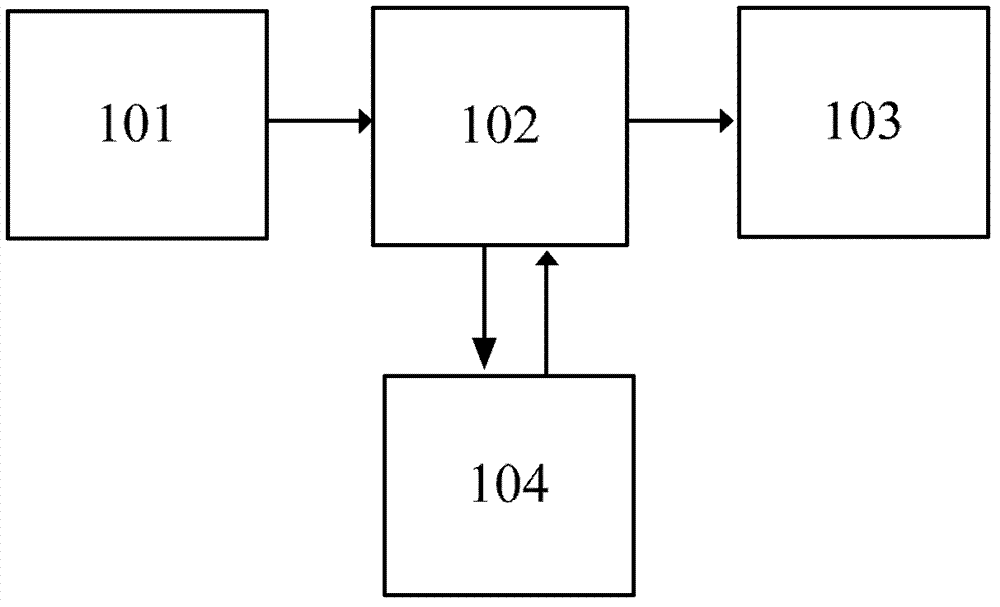

[0059] The diamond wire saw sand planting method provided by the present invention has been described in detail above, and the diamond wire saw sand planting system provided by the present invention will be described in detail below.

[0060] refer to image 3 , image 3 It is a structural schematic diagram of a diamond wire saw sand planting system provided by the present invention. The diamond wire saw sand planting system includes: a coating device 101 for uniformly coating the resin adhesive on the surface of the core wire; Diamond particles are negatively charged, the core wire is positively charged, and the negatively charged diamond particles are sprayed into the resin binder on the surface of the positively charged core wire 102; used for core wire curing Shaped curing device 103 .

[0061] Preferably, the diamond wire saw sand planting system in the embodiment of the present invention further includes: a recovery device 104, the recovery device 104 is used to collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com