Chemical-mechanical grinding device and method

A technology of chemical machinery and grinding equipment, which is applied in the direction of grinding equipment, grinding machine tools, electrical components, etc., can solve the problems of low utilization rate of grinding fluid, increase of process cost, waste of grinding fluid, etc., to reduce process cost, improve utilization rate, The effect of consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

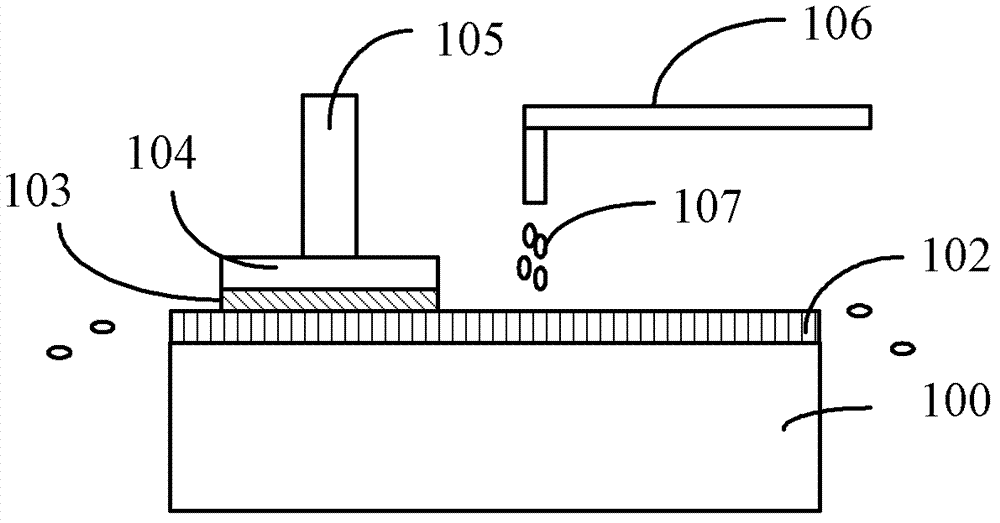

[0031] The inventor found that when using the existing chemical mechanical grinding device for grinding, the grinding liquid flowing out from the edge of the grinding pad also contains a large amount of unused grinding liquid stock solution. If the grinding liquid is directly discharged from the waste liquid pipeline, it will cause The great waste of grinding fluid and the low utilization rate of grinding fluid increase the process cost.

[0032] In order to solve the above problems, the inventor proposes a chemical mechanical polishing device.

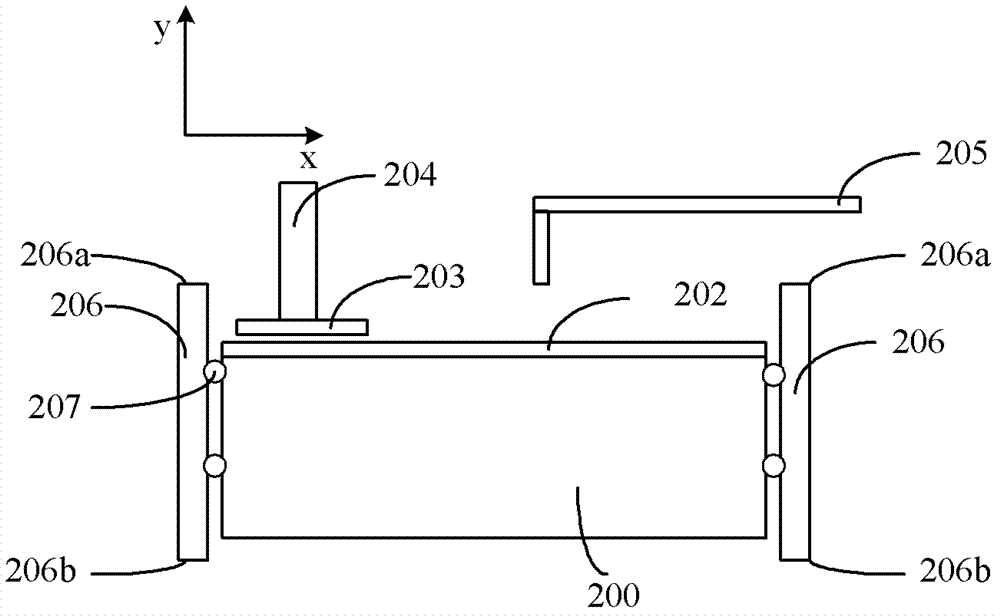

[0033] Please refer to figure 2 , is a schematic structural diagram of the chemical mechanical polishing device of the present invention.

[0034] The chemical mechanical polishing device comprises:

[0035] Grinding disc 200, described grinding disc 200 is for placing grinding pad;

[0036] Polishing pad (Polish Pad) 202, described polishing pad lays on described grinding disk 200, is used for grinding the surface to be ground of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com