Improved type front shock absorption device of tricycle

A tricycle, front shock absorber technology, applied in axle suspension, bicycle accessories, transportation and packaging, etc., can solve the problems of small bearing capacity, shorten the service life of shock absorbers, damage the front shock absorber, etc., to improve the service life , Increase the working stroke and improve the effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

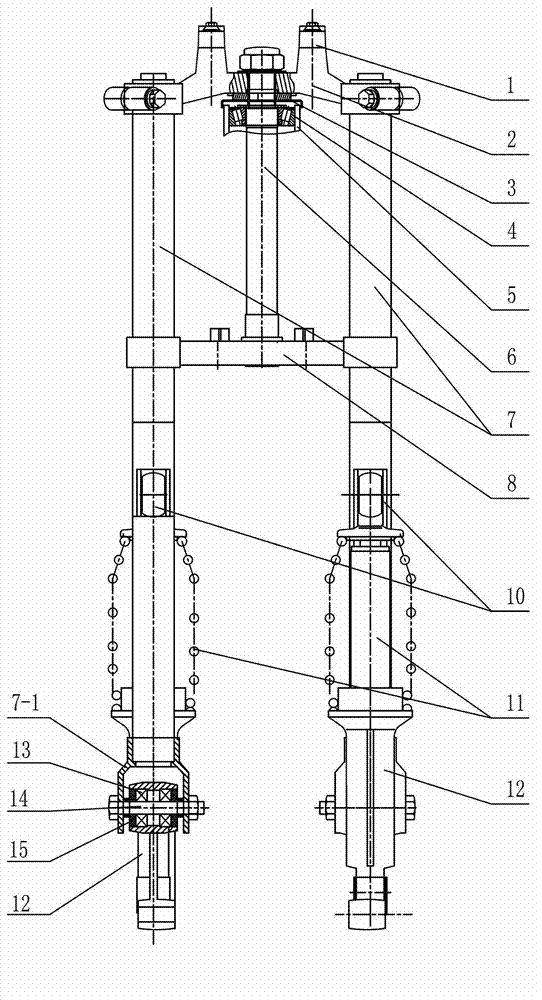

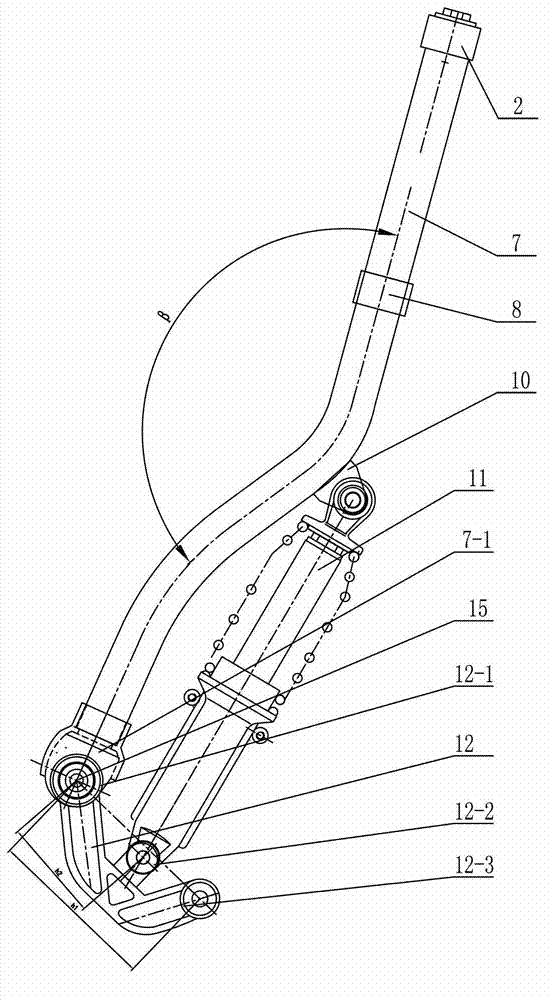

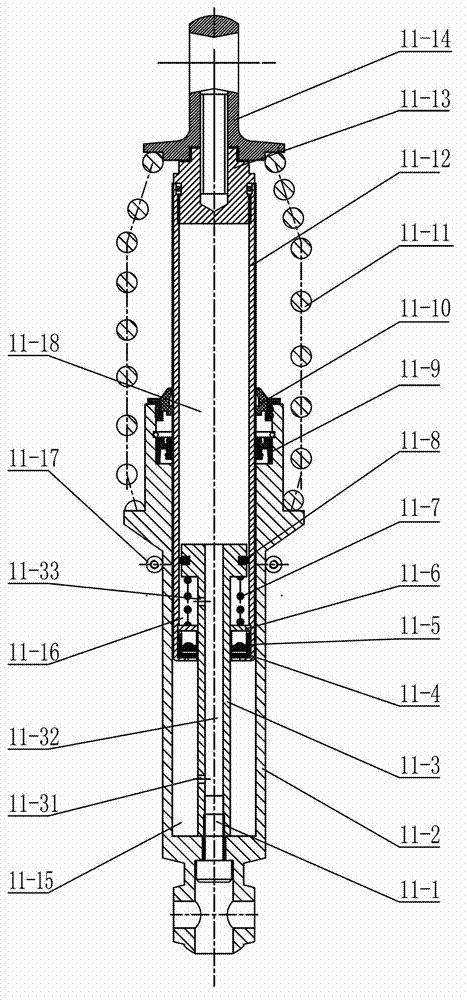

[0014] See Figure 1~3 As shown, the improved tricycle front shock absorber of the present invention includes a front fork assembly and two front shock absorbers 11, and the front fork assembly includes two front fork tubes 7, an upper joint connected to the two front fork tubes 7 Plate 2 and lower connecting plate 8 and lower hinged plate 12, the rear bottom of two front fork tubes 7 are hinged on the supporting seat 12-1 of lower hinged plate 12, the present invention is to make the lower hinged plate 12 hinged on the front fork tube 7 can be more Good flexible rotation, the bottom of the front fork tube 7 is fixed with a connector 7-1, and the support seat 12-1 of the lower hinge plate 12 is arranged in the connector 7-1, and at least one rolling bearing 13 is installed on the support seat 12-1. 1 and connected with the connecting shaft 14, the connecting shaft 14 is installed on the connecting head 7-1 through fasteners, one side of the connecting shaft 14 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com