A clamping device for an aircraft nose wheel

A technology of nose wheel and holding clip, which is applied in the direction of launching/dragging transmission device, etc., which can solve the problems of disengagement of holding clip device, side slipping of nose wheel, easy to cause accidents, etc., achieve reliable locking state and prevent side slipping of nose wheel , Reliable effect of clamping state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with specific embodiments, the clamping device is further described:

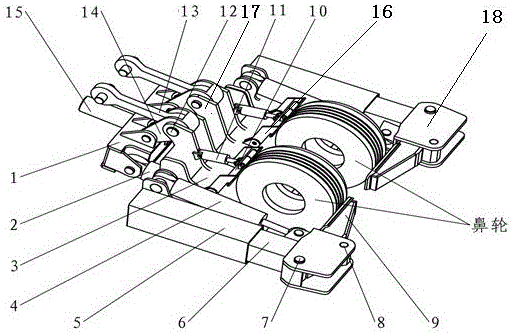

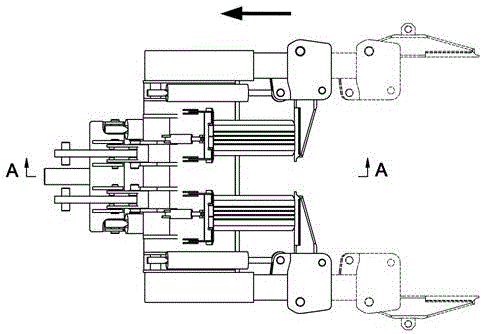

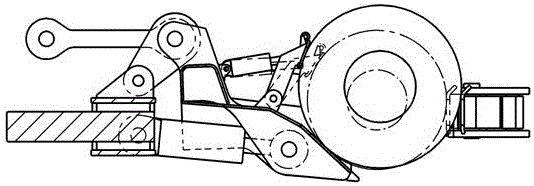

[0023] A clamping device for an aircraft nose wheel, comprising a vehicle frame, characterized in that an upper link 13, a lower link 14, a lifting cylinder 2, a rotating pin 15, a swing frame 1, a pressing bracket 16, a pressing Oil cylinder 11, upper pressing arm 10, hinge pin 12, clamp 9 and clamp pin 7, swing frame 1 is hinged with vehicle frame through rotation pin 15, front end of lifting oil cylinder 2 is hinged with swing frame 1, The rear end is hinged with the lower end of the pallet 3, and the upper end of the front part of the pallet 3 is provided with a lifting turret 17 and a pressing bracket 16. The contact working plane between the rear part of the pallet 3 and the nose wheel is an inclined plane to constrain the vertical direction of the nose wheel. The front end of the lifting turret 17 is provided with a hinge pin 12, the rear end is provided with a compression...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com