Preparation method of 2-acetylchloromethoxy-1,3-dichloropropane

A technology of chloromethoxy and dichloropropane, which is applied in the field of preparation of 2-acetylchloromethoxy-1.3-dichloropropane, can solve the problems of high cost, inconvenient use, easy discoloration and the like, and achieves the reaction time Short, less side reactions, the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

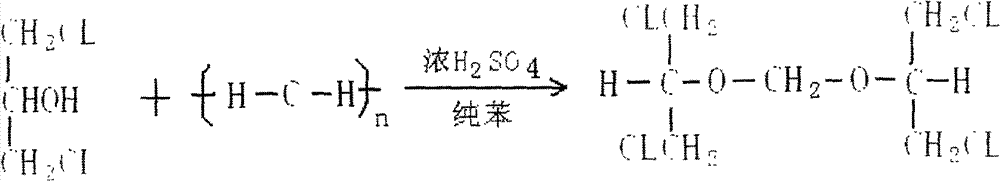

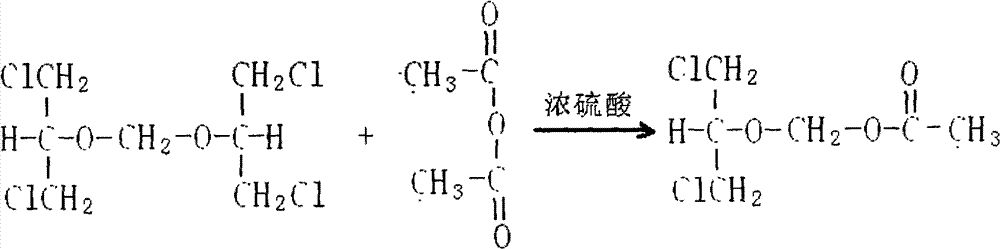

Method used

Image

Examples

Embodiment 1

[0030] Extract the following substances by weight ratio:

[0031]

[0032] In a clean and dry reaction kettle, add 1.3-dichloro-2-propanol, paraformaldehyde, and sulfuric acid, slowly raise the temperature, raise the temperature to 96-98°C in 2 hours, keep it warm for 2 hours, after the heat preservation is completed, cool down to 10°C and start dripping Add acetic anhydride, keep the temperature at 15-20°C, after the addition, raise the temperature at 35-40°C and keep it warm for 10 hours, add potassium acetate, stir, recover the acetic anhydride in vacuum to 100°C, cool down to 20°C, filter, and pump the filtrate into the refined In the distillation still, collect 115°C / 10mmHg distillate to obtain 2-acetylchloromethoxy-1.3-dichloropropane with a weight yield of 80% and a content of ≥95%.

Embodiment 2

[0034] Starting from the second charge, extract the following substances by weight ratio:

[0035]

[0036]

[0037] In a clean and dry reaction kettle, add 1.3-dichloro-2-propanol, paraformaldehyde, sulfuric acid, slowly raise the temperature, raise the temperature to 96-98°C in 2 hours, keep it warm for 2 hours, after the heat preservation is complete, cool it down to 10°C, add 250kg of the distillate steamed below 115°C / 10mmHg during the rectification described in Example 1, then start to add acetic anhydride dropwise, the temperature remains at 15-20°C, after the addition is completed, the temperature is raised at 35-40°C for 10 hours, Add potassium acetate, stir, vacuum recover acetic anhydride to 100°C, cool down to 20°C, filter, pump the filtrate into a rectification kettle, collect 115°C / 10mmHg distillate to obtain 90% weight yield, content ≥ 95% 2-Acetylchloromethoxy-1,3-dichloropropane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com