Petronaphthalene rectification reflux temperature control device and control method thereof

A technology of reflux temperature and control device, which is applied in the field of petroleum naphthalene rectification, can solve the problems such as difficulty in controlling the reflux temperature of ethylene tar, and achieve the effects of easy control of reflux temperature, production cost saving, and easy control of recovery of naphthalene gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

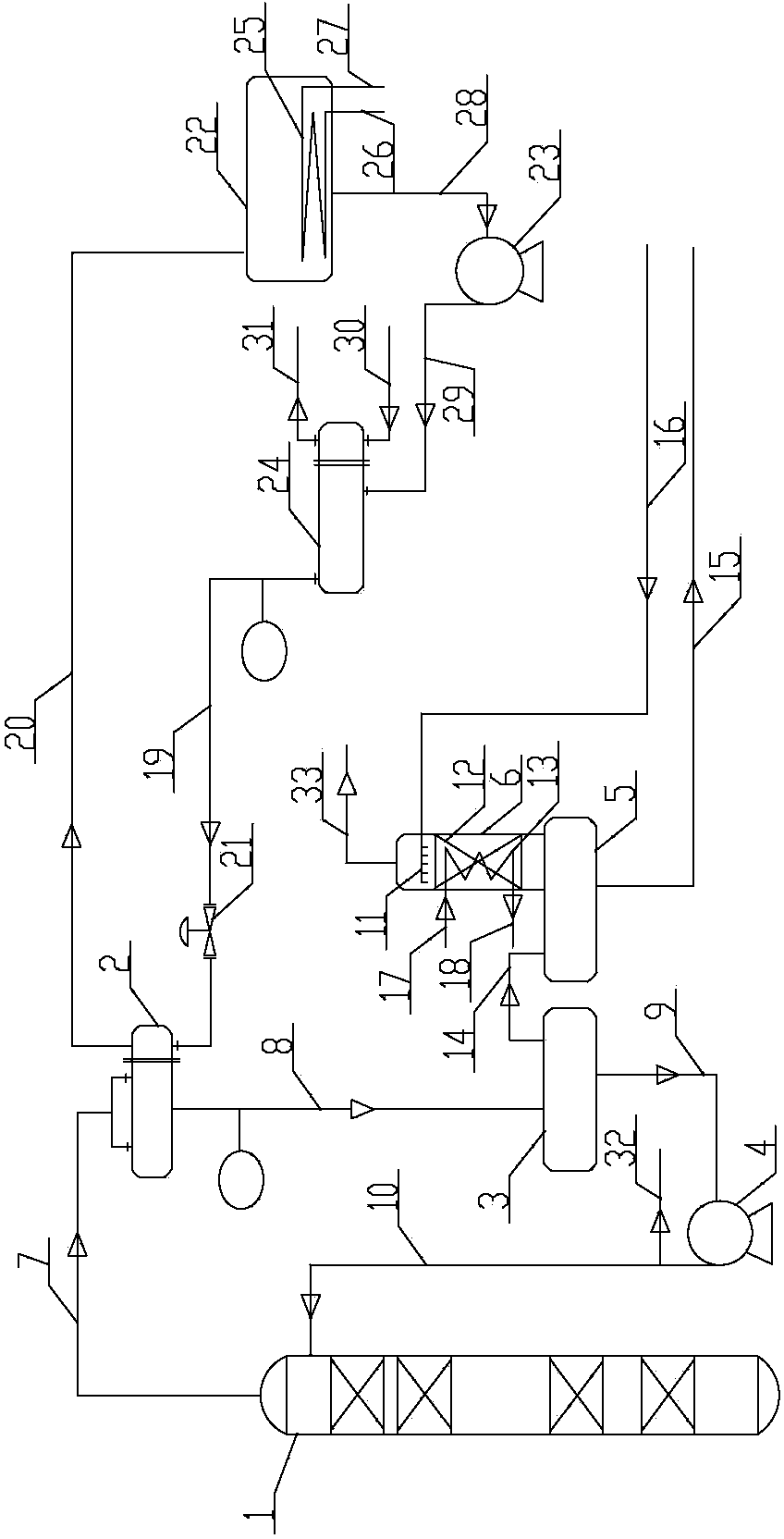

[0019] Embodiment 1, this petroleum naphthalene rectification reflux temperature control device comprises rectification tower 1, condenser 2, reflux tank 3, tower top reflux pump 4, naphthalene gas absorption tank 5 and naphthalene gas absorption tower 6; Naphthalene gas absorption tank The upper end of 5 and the lower end of naphthalene gas absorption tower 6 are fixedly connected together and communicate with each other. There is a rectification tower gas outlet at the top of rectification tower 1, and a rectification tower liquid inlet is arranged at the top of rectification tower 1. The gas outlet and the tube-side inlet of the condenser 2 are fixedly connected together through the first pipeline 7, the tube-side outlet of the condenser 2 and the top inlet of the reflux tank 3 are fixedly connected together through the second pipeline 8, and the bottom outlet of the reflux tank 3 The inlet of the tower top reflux pump 4 is fixedly connected together by the third pipeline 9,...

Embodiment 2

[0020] Embodiment 2 differs from Embodiment 1 in that: a hot water tank 22, a hot water circulation pump 23 and a cooler 24 are arranged outside the condenser 2; a heat conduction oil coil 25 is fixedly installed in the hot water tank 22 12th pipeline 26 and 13th pipeline 27 are fixedly connected to the inlet and outlet of the heat-conducting oil coil 25 respectively, and the outer ends of the 12th pipeline 26 and the thirteenth pipeline 27 are located outside the hot water tank 22; The bottom outlet of the water tank 22 and the inlet of the hot water circulation pump 23 are fixedly connected together through the fourteenth pipeline 28, and the outlet of the hot water circulation pump 23 and the tube side inlet of the cooler 24 are fixedly connected together through the fifteenth pipeline 29 , the tube-side outlet of the cooler 24 and the shell-side inlet of the condenser 2 are fixedly connected together through the tenth pipeline 19, and the shell-side outlet of the condenser ...

Embodiment 3

[0021] Embodiment 3, differs from Embodiment 1 and Embodiment 2 in that: the 18th pipeline 32 is fixedly installed on the 4th pipeline 10, and the 19th pipeline 33 is fixedly connected on the gas outlet of the naphthalene gas absorption tower 6 , a vacuum pump is fixedly installed on the nineteenth pipeline 33 . In this way, the gas phase not absorbed by the naphthalene gas absorbing liquid after the mass transfer and heat transfer reaction takes place is discharged through the nineteenth pipeline 33 and the vacuum pump.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com