Novel cotton condensing device

A new type of technology for condensing cotton, which is applied in the field of new condensing equipment, can solve the problems of strong fan vibration, high failure rate of cotton condenser, and high noise, so as to improve the effect of dust filtration, improve the effect of dust filtration and impurity removal, and overcome the failure rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

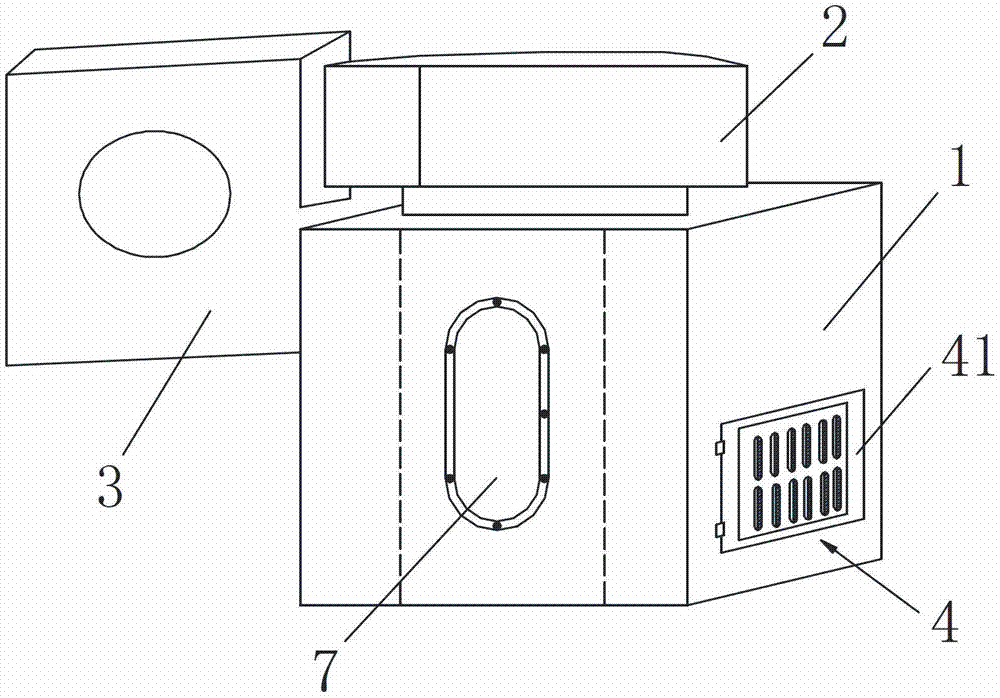

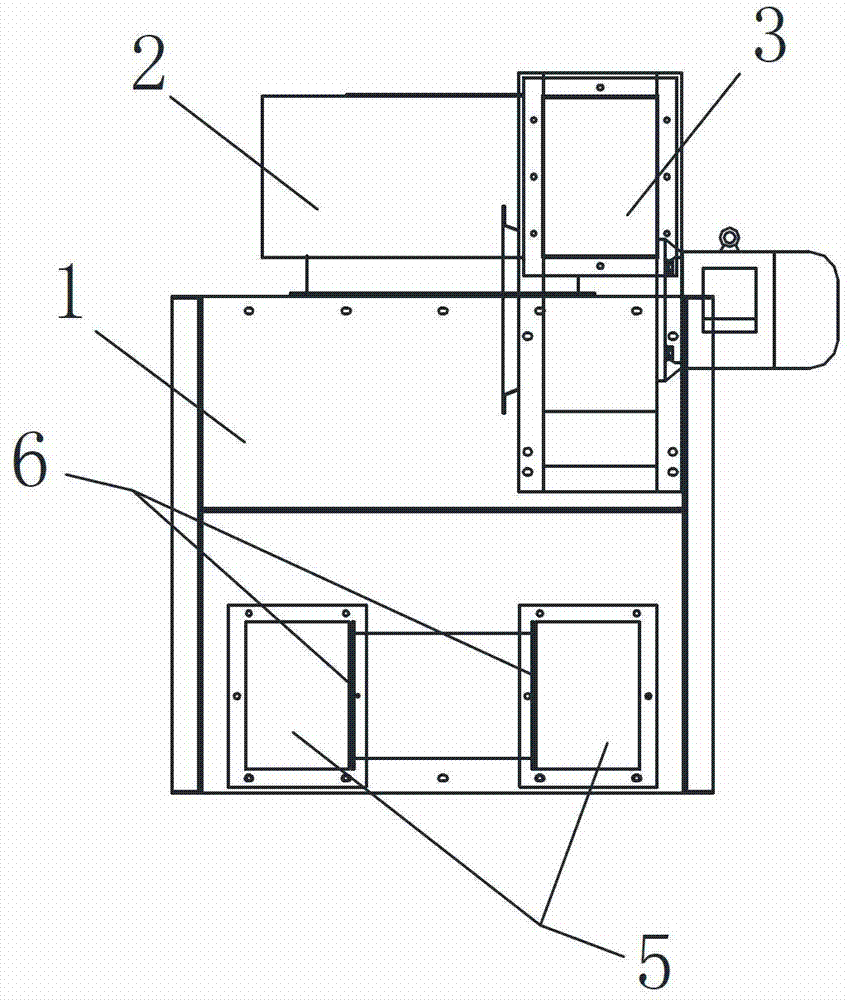

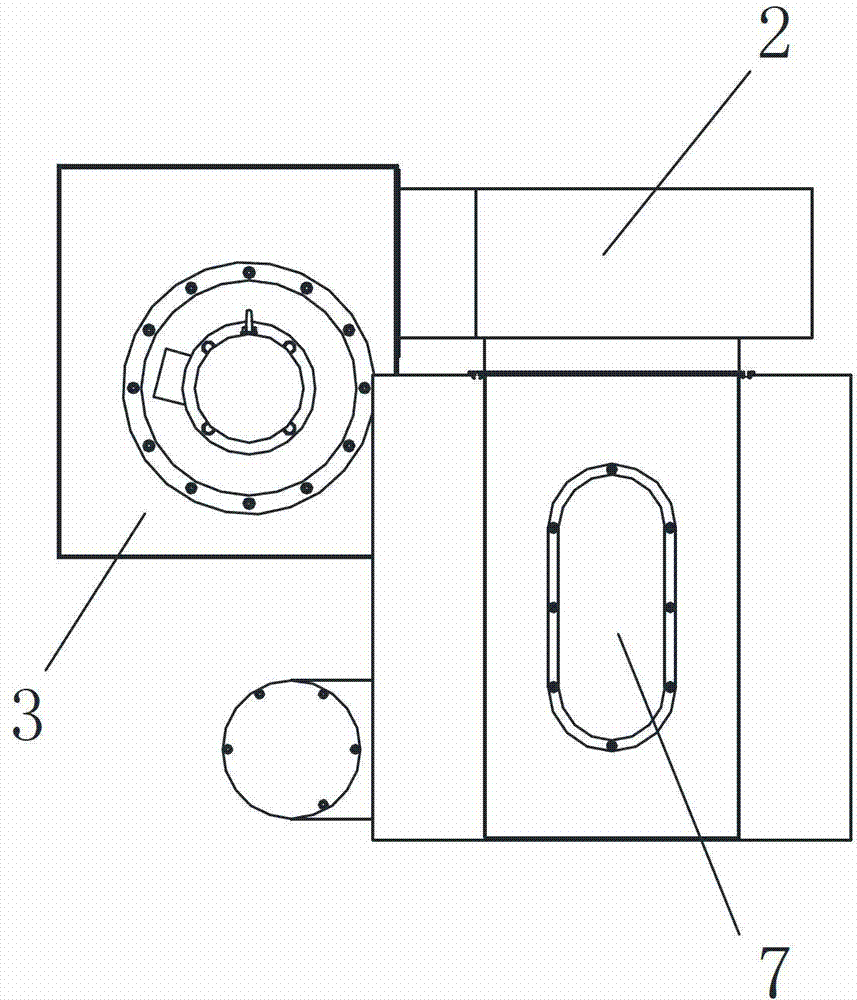

[0024] combine Figure 1 to Figure 3 As shown, the novel condensing device includes a condenser housing 1, and a nodding cylinder is arranged inside the condenser housing, and meshes are arranged on the nodding cylinder. Preferably, the mesh holes are formed along the side wall of the nodding cylinder It gradually becomes smaller from top to bottom. The linters and dust impurities mixed in the raw materials (fibers) are of different sizes. During the falling process inside the doffing cylinder, it is beneficial to form layers and remove impurities. The relatively large linters pass through the doffing tube. The mesh holes in the upper part of the cotton cylinder are sucked out of the doffing cylinder, and the relatively small dust particles are sucked out of the doffing cylinder through the upper mesh holes, and the rest can also be sucked out from the lower mesh holes, which is beneficial to improve the dust filtering effect.

[0025] On the top of the condenser shell 1, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com