TJC buckling restrained bracing member

A support member and buckling restraint technology, applied in building components, building structure, earthquake resistance, etc., can solve the problems of increasing cross-sectional area, high production cost, not very economical, etc., to improve bending resistance, save installation costs, The effect of improving stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

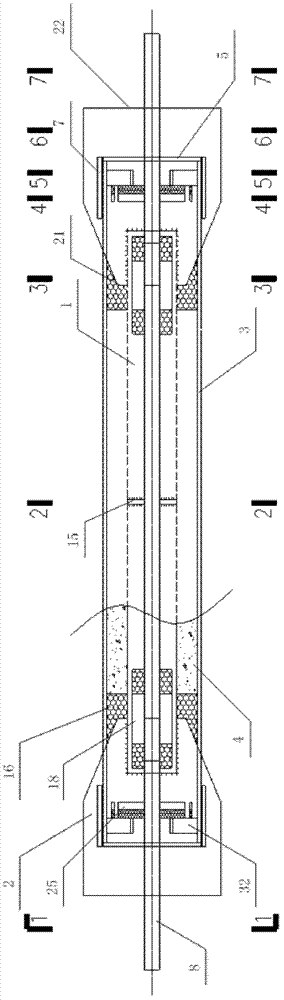

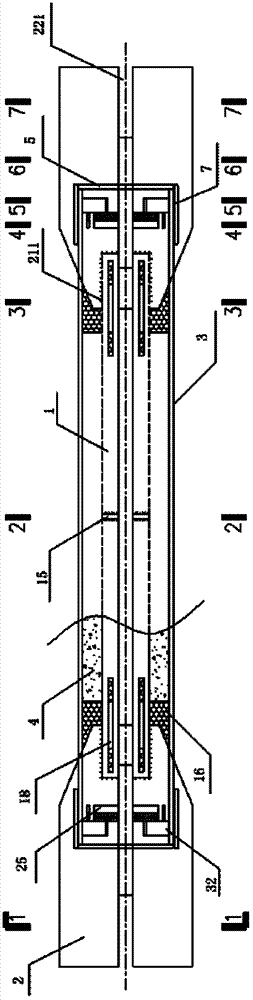

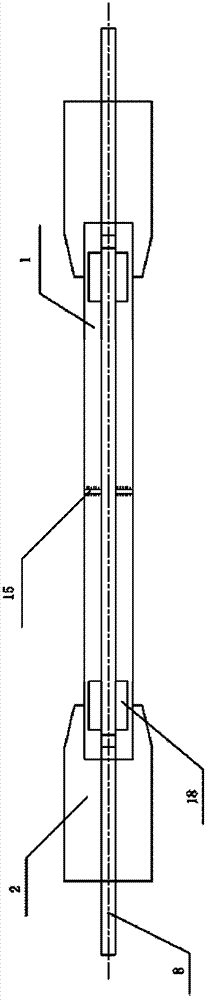

[0046]The invention provides a TJC buckling restraint support member, which can also be called a TJC buckling restraint support. The support end nodes are made of high-strength steel, and the core energy-consuming section, that is, the core material part, is made of low-strength steel or low yield point steel, reducing The appearance size of the support and the amount of steel used are optimized; the stiffener of the node at the end of the support passes through the sleeve, so that the stability design and the strength design are not coupled, and the support design can be the most economical; the bending resistance of the support node is improved through the outer collar of the node. The overall stability of the support is improved; through the interaction between the clamping plate and the angle steel, after the support core plate is fatigued and fractured, the internal force is transmitted to the support sleeve, which avoids the general buckling-constrained support breaking un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com