Compressor with compression pump body support member

A technology for compressing pumps and supports, which is applied to pump components, liquid fuel engines, and parts of pumping devices for elastic fluids. Performance and stability, reduction of welding deformation, effect of reducing welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

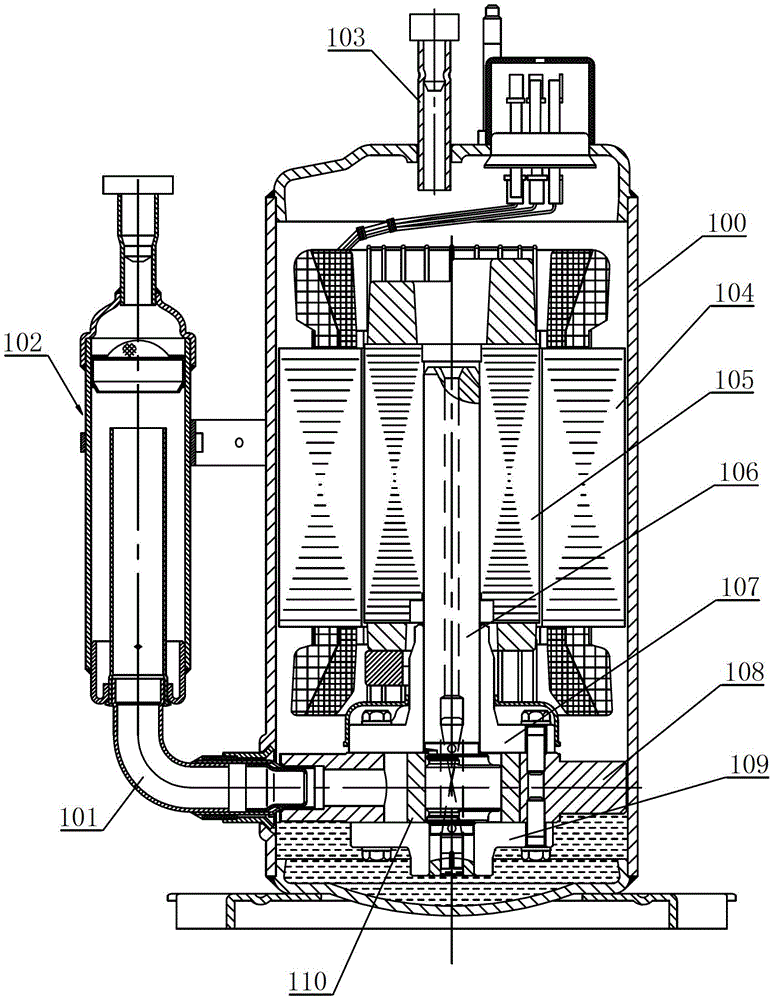

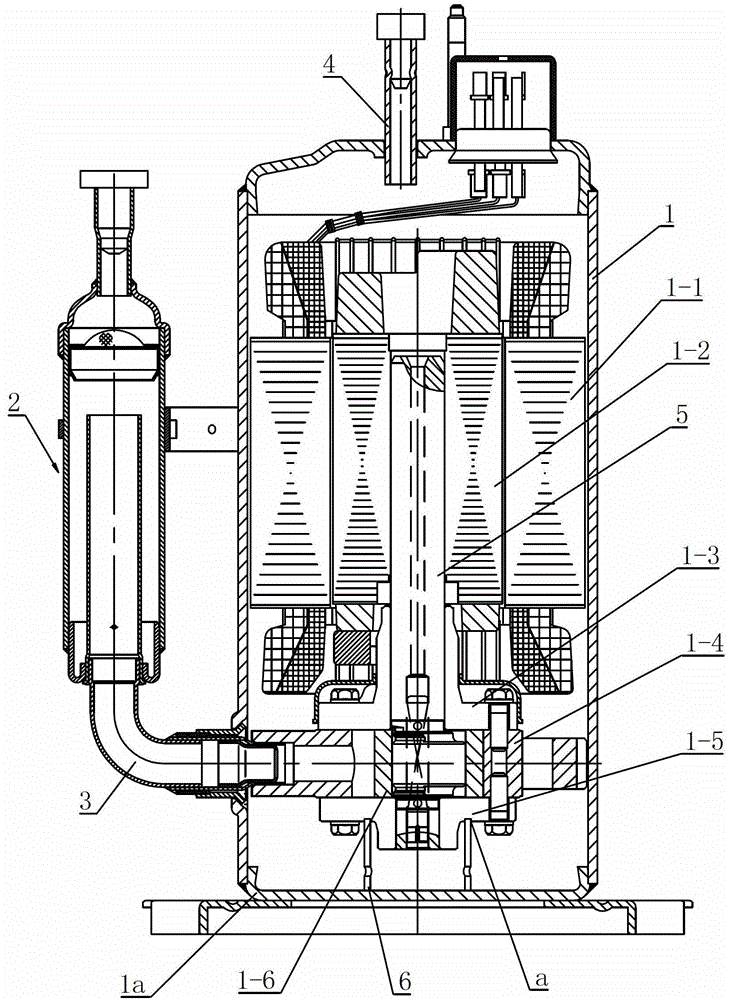

[0028] Such as figure 2 As shown, the compressor of this embodiment includes a closed casing 1, a motor assembly and a compression pump body arranged inside the closed casing 1, a gas-liquid separator 2 arranged on one side of the closed casing 1, and a gas-liquid separator 2 The intake elbow 3 communicates with the compression pump body of the compressor, so that the refrigerant enters the cylinder of the compressor from the gas-liquid separator 2 . The exhaust pipe 4 is arranged on the upper end of the closed casing 1, and the compressed high-temperature and high-pressure gas enters the circulation system from the exhaust pipe 4 . For ease of description, the figure 2 The axis direction of the middle compressor rotating shaft 5 defines up and down.

[0029] The motor assembly of the present invention includes a stator 1-1 fixed on the upper inner wall of the closed casing 1, and a rotor 1-2 rotatably arranged in the stator 1-1, and the compressor shaft 5 is driven to rot...

Embodiment 2

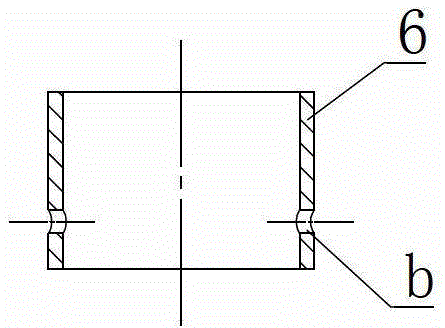

[0033] Also refer to Figure 5 , Image 6 and Figure 7 , the compression pump body support 6' of this embodiment is integrated with the lower flange 1-5, that is, the compression pump body support 6' is a part of the lower flange 1-5, and the compression pump body support 6' is located at The end of the boss part of the lower flange 1-5, the bottom of the compression pump body support 6' (that is, the bottom of the boss part of the lower flange 1-5) is directly in contact with the lower cover 1a to support the compression pump body . Four oil passage holes b arranged at intervals along the circumference are also processed on the lower peripheral wall of the compression pump body support member 6', through which refrigerated oil can enter the compression pump body, thereby lubricating the parts in the compression pump body. In this embodiment, the support member 6' of the compression pump body is made integrally with the lower flange 1-5, and the lower flange 1-5 is used fo...

Embodiment 3

[0035] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 2 is that: an annular deposition groove c is processed on the upper surface of the lower cover 1a, and the deposition groove c is recessed downward from the upper surface of the lower cover 1a, so that the freezing oil The sunken impurities may be deposited in the deposition groove c. Setting the sedimentation groove c on the upper surface of the lower cover 1a does not increase the height of the compression pump body support (that is, the height of the closed casing), nor does it affect its function of isolating impurities. The number of annular deposition grooves c can be set according to needs. In this embodiment, two rings of annular deposition grooves c located on the outside of the compression pump body support 6' are provided. In addition, the deposition groove c can also be a plurality of spaced apart and form annular arc grooves or circular grooves or other grooves of different s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com