Detection method for equivalent diameter of anticorrosive coating damaged surface of buried steel pipeline

A technology of equivalent diameter and anti-corrosion layer, which is applied in the field of indirect detection of the equivalent diameter of the damaged surface of the anti-corrosion layer of buried steel pipelines, can solve the problem that the damage size of the anti-corrosion layer cannot be accurately given.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

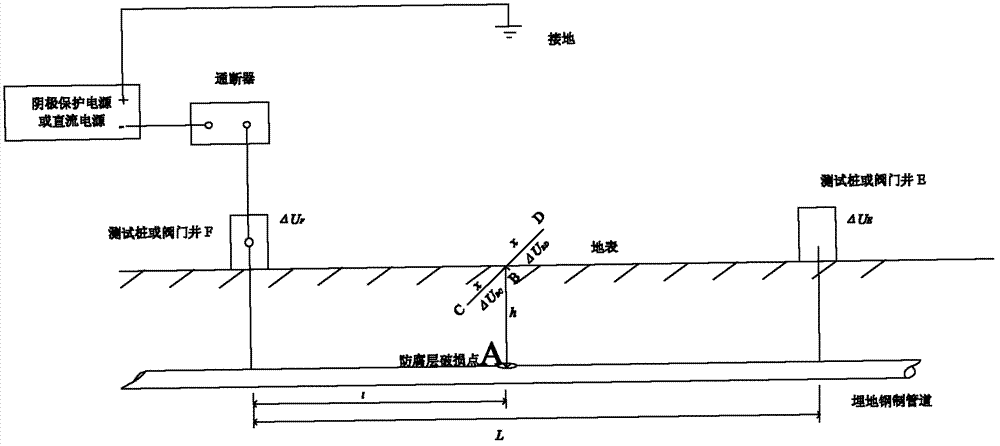

[0080] Example 1: There is a steel buried pipeline with a diameter of 325*6mm, the transmission medium is natural gas, and the operating pressure is 1.6MPa; the anti-corrosion protection adopts an applied current and an additional 3PE anti-corrosion layer. The surrounding environment of the pipeline is farmland and the soil is moist. There are no branches in the pipeline in the detection area.

[0081] Detection tools: PCS-2000 DC potential gradient detector produced in Australia, Japanese Fuji PL960 metal pipeline and cable positioner, distance measuring wheel, and vernier caliper.

[0082] Follow the steps below when testing:

[0083] 1. First, add the switch in the DC potential gradient detector PCS-2000 to the wire between the cathodic protection device of the applied current and the pipeline to realize the periodic on-off of the current on the wire (1 / 3 second on, 2 / 3 seconds off); adjust the applied current device so that the difference between the ground potential of ...

Embodiment 2

[0089] Example 2: There is a steel buried pipeline with a diameter of 219*6mm, the transmission medium is natural gas, and the operating pressure is 0.4MPa; anti-corrosion protection adopts sacrificial anodes and an additional 3PE anti-corrosion layer. The pipeline is located on the sidewalk next to the road in the urban area, and the sidewalk is laid For cement sand bricks. The detection area is between two valve wells, about 1500m long, and the pipeline between the two valve wells has no branches.

[0090] Detection tools: PCS-2000 DC potential gradient detector produced in Australia, Japanese Fuji PL960 metal pipeline and cable positioner, distance measuring wheel, vernier caliper, 220V AC current generator, constant voltage and constant current potentiometer.

[0091] Follow the steps below when testing:

[0092] 1. First, apply periodic on-off (1 / 3 second on, 2 / 3 second off) current to the pipeline through the switch in the DC potential gradient detector DCVG at the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com