Mg/Mo/SiC extreme ultraviolet multilayer film reflector and manufacturing method thereof

A production method and multi-layer film technology, applied in the direction of chemical instruments and methods, mirrors, layered products, etc., can solve the problems of not meeting broadband reflectivity, narrow effective bandwidth, etc., to achieve widening bandwidth, improving reflectivity, reducing The effect of the number of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

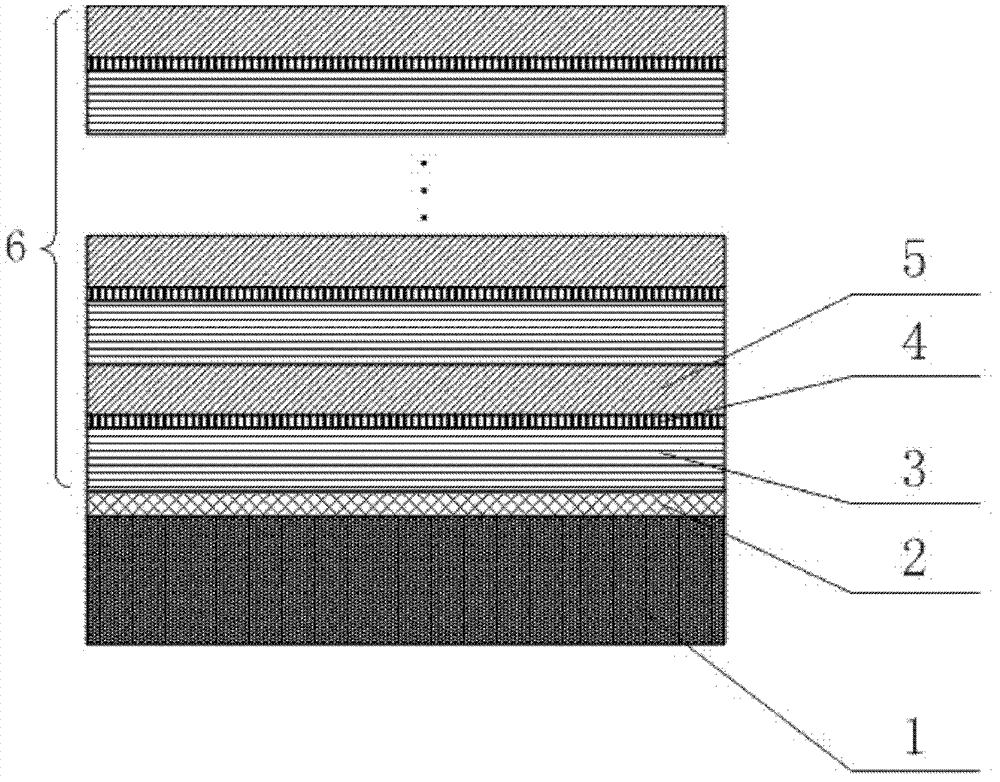

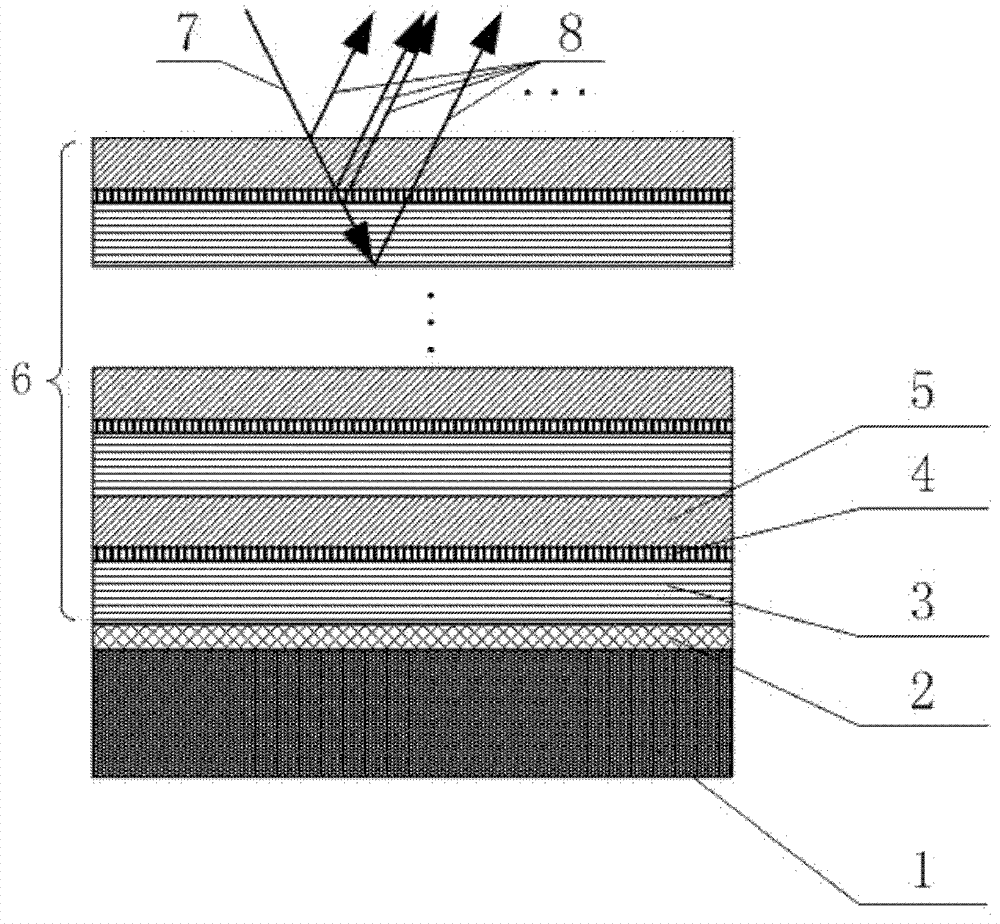

[0024] The manufacturing method of Mg / Mo / SiC extreme ultraviolet multilayer mirror, such as figure 1 As shown, first, ultra-smooth single crystal silicon wafers (crystal orientation of (100)) or glass are selected as the substrate 1 of the reflector, and the substrate roughness is 0.3-0.5 nm. Then, a SiC film with a thickness of 2-3 nanometers is plated on the substrate as a primer layer 2. Then the Mg film layer 3, Mo film layer 4 and SiC film layer 5 are repeatedly plated on the bottom layer 2 to form a Mg / Mo / SiC periodic multilayer film 6, the number of cycles is 30-40, the thickness of Mg and the thickness of the cycle The ratio is 0.7-0.8, and the ratio of the Mo film layer to the periodic thickness is 0.07-0.1. In the periodic multilayer film 6, the first layer plated in each cycle is a Mg layer, the second layer is a Mo layer, and the last layer is a SiC layer. After 30-40 cycles of plating, excellent performance can be obtained Mg / Mo / SiC extreme ultraviolet multilayer ...

Embodiment 2

[0027] Mg / Mo / SiC extreme ultraviolet multilayer film reflector, the reflector is composed of (100) silicon wafer as the substrate, the bottom layer and the Mg / Mo / SiC periodic multilayer film, the bottom layer is a thickness of 2 nanometers SiC is plated on the substrate, and the Mg / Mo / SiC periodic multilayer film is plated on the bottom layer. The first layer plated from bottom to top in each cycle is the Mg film layer, and the second layer is the Mo film layer. The last layer is the SiC film, the number of cycles is 30, the total thickness of the Mg / Mo / SiC multilayer film is 450 nanometers, of which the thickness of the Mg film is 9 nanometers, the thickness of the Mo film is 1 nanometer; the SiC film The thickness is 3 nanometers.

[0028] The manufacturing method of Mg / Mo / SiC extreme ultraviolet multilayer mirror includes the following steps:

[0029] 1) SiC with a thickness of 2 nanometers is plated on a super smooth silicon wafer or glass substrate with a crystal orientation ...

Embodiment 3

[0032] Mg / Mo / SiC extreme ultraviolet multilayer mirror. The mirror is composed of a glass substrate, a bottom layer and a periodic Mg / Mo / SiC multilayer film. The bottom layer is SiC with a thickness of 3 nanometers, which is plated on the substrate. / Mo / SiC periodic multilayer film is plated on the bottom layer, the first layer plated from bottom to top in each cycle is the Mg film layer, the second layer is the Mo film layer, and the last layer is the SiC film layer. The number is 40, the total thickness of the Mg / Mo / SiC multilayer film is 640 nanometers, among which the thickness of the Mg film layer is 11 nanometers, the thickness of the Mo film layer is 1.5 nanometers, and the thickness of the SiC film layer is 4.5 nanometers.

[0033] The manufacturing method of Mg / Mo / SiC extreme ultraviolet multilayer mirror includes the following steps:

[0034] 1) SiC with a thickness of 3 nanometers is plated on an ultra-smooth silicon wafer or glass substrate with a crystal orientation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com