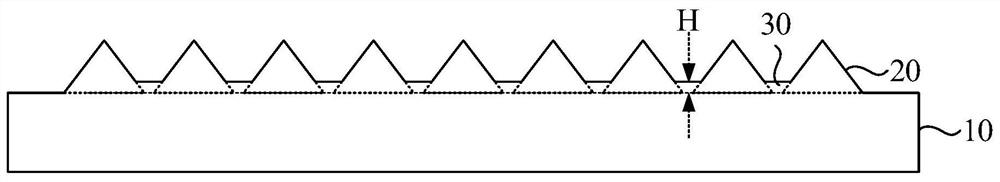

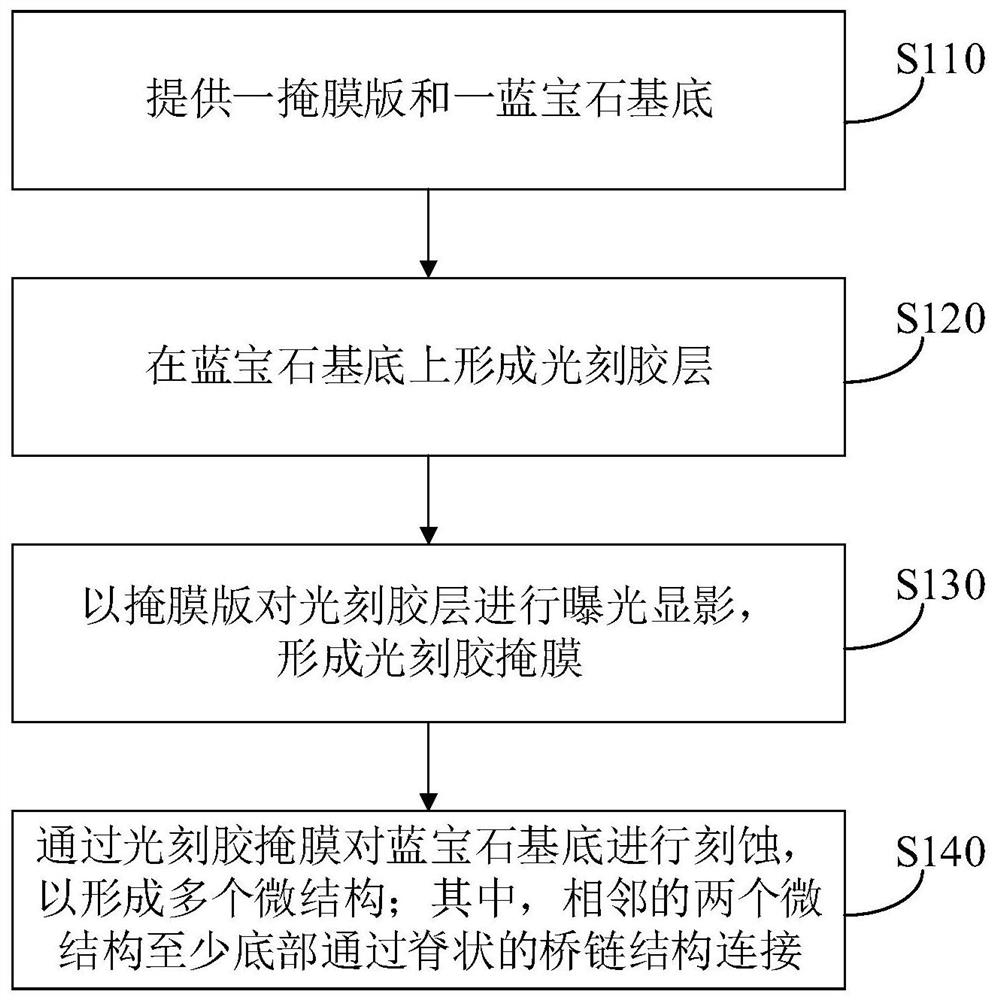

Bridge chain type patterned sapphire substrate, preparation method and LED epitaxial wafer

A technology for patterning sapphire and sapphire substrates, which is used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. to increase the reflection area, increase the reflection interface area, and improve the reflection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

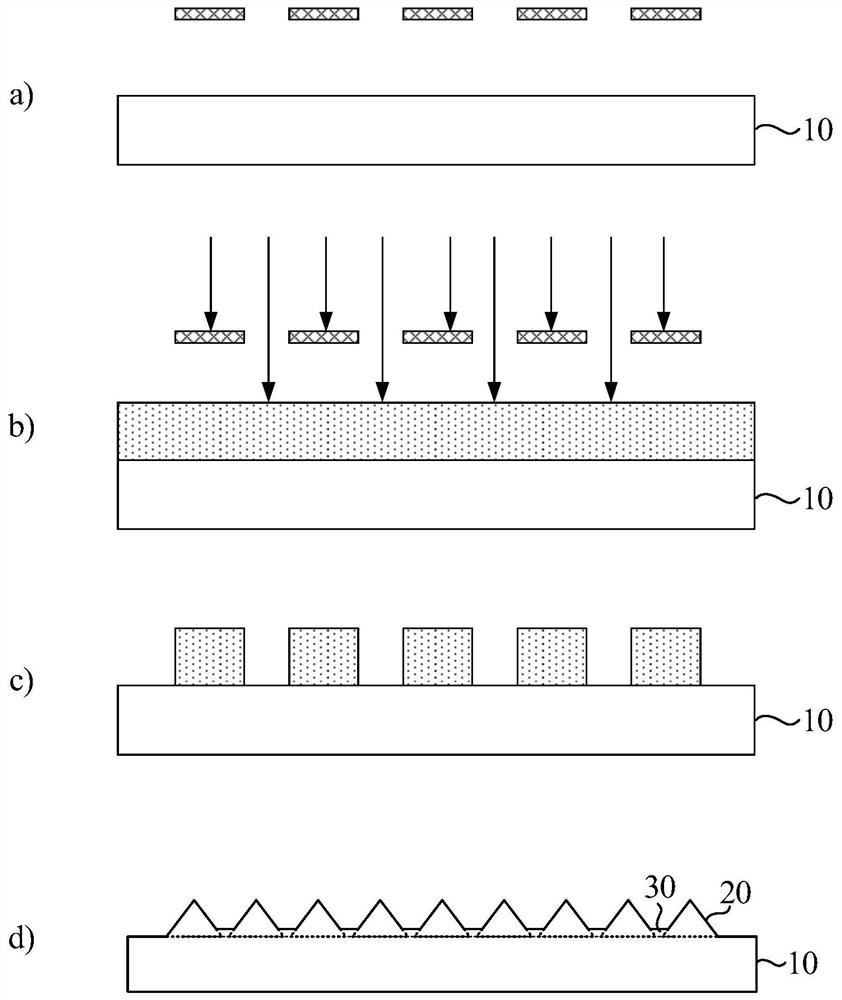

[0077] Based on the various implementation modes provided by the present invention, the bridge-chain patterned sapphire substrate and the preparation method of the present invention will be introduced below with a specific example. Figure 15 It is a cross-sectional SEM test diagram of a photoresist mask provided by an embodiment of the present invention under different magnifications, Figure 16 The embodiment of the present invention provides a cross-sectional SEM test diagram of a bridge-chain patterned sapphire substrate under different magnifications, Figure 17 It is a top-view SEM test diagram of a bridge-chain patterned sapphire substrate under different magnifications provided by the embodiment of the present invention, Figure 18 It is a top-view SEM test diagram of another bridge-chain patterned sapphire substrate under different magnifications provided by the embodiment of the present invention. The preparation method includes:

[0078] S311. Prepare a special pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com