Led drive circuit and led driving method

一种LED驱动、电路的技术,应用在电灯电路布置、电光源、电气元件等方向,能够解决闪烁等问题,达到抑制切换损耗的增加、避免过度增大的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] (Basic structure of an LED drive circuit using a DC / DC converter)

[0034] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. The invention is applicable to both buck and boost converter types. However, in the following description, the case applicable to the buck converter type will be described as an example.

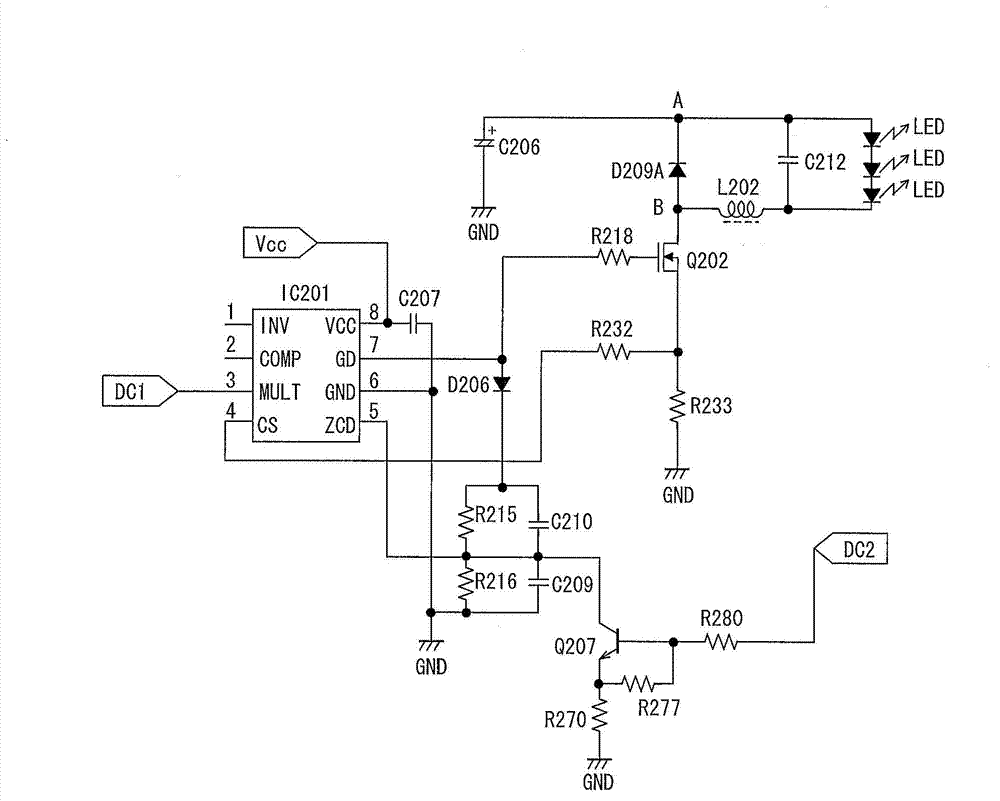

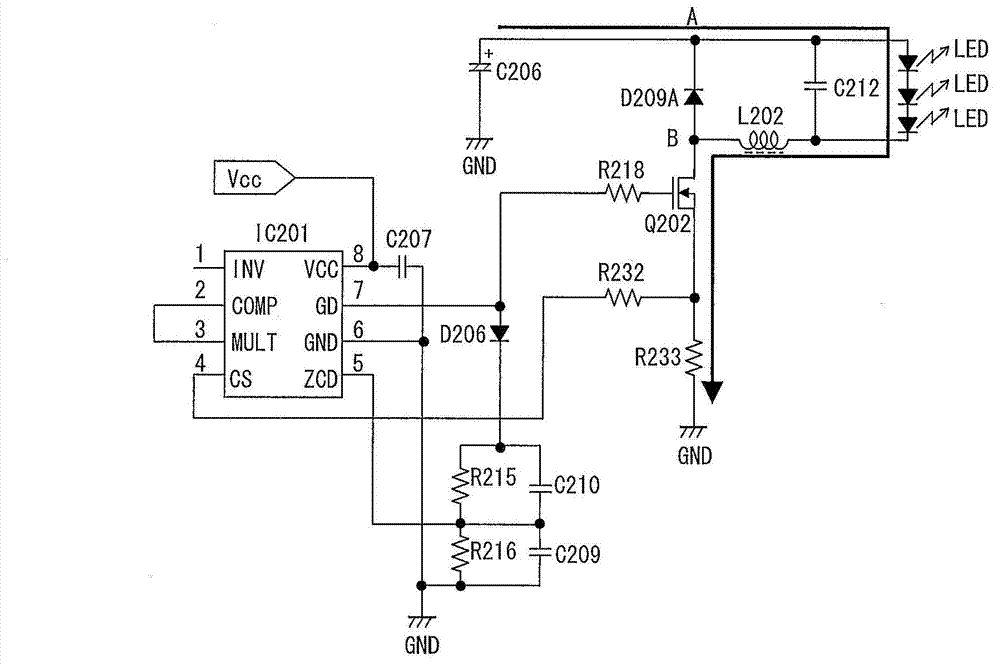

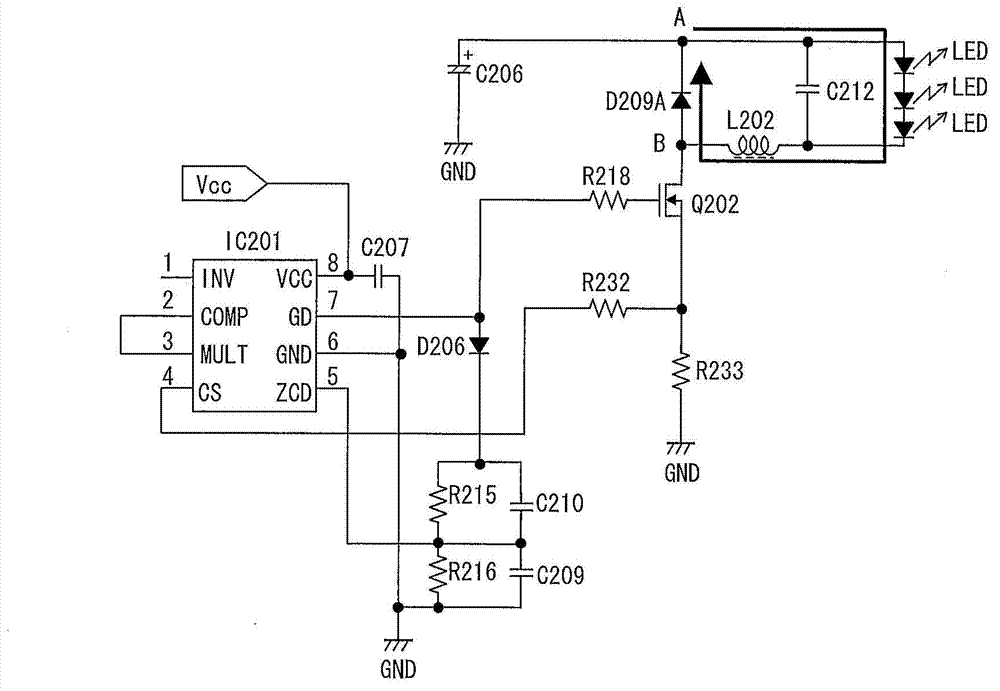

[0035] figure 2 with image 3 It is a circuit diagram showing a typical structure of an LED drive circuit using a conventional PWM dimming method. This circuit shows a rated current circuit, and in this rated current circuit, L6562 (trade name) manufactured by STMicro is used as a control IC. Figure 4 said in the use of figure 2 and image 3 The current flowing through the LED when the LED driving circuit shown is driving the LED. This LED drive circuit includes a step-down converter type DC / DC converter (hereinafter simply referred to as “inverter”) including an inductor L202 , a transistor Q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com