Composite pane having an electrically heatable coating

A composite window, electric heating technology, applied in the application of automotive windows, the field of automotive windows, to achieve the effect of uniform heating power distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

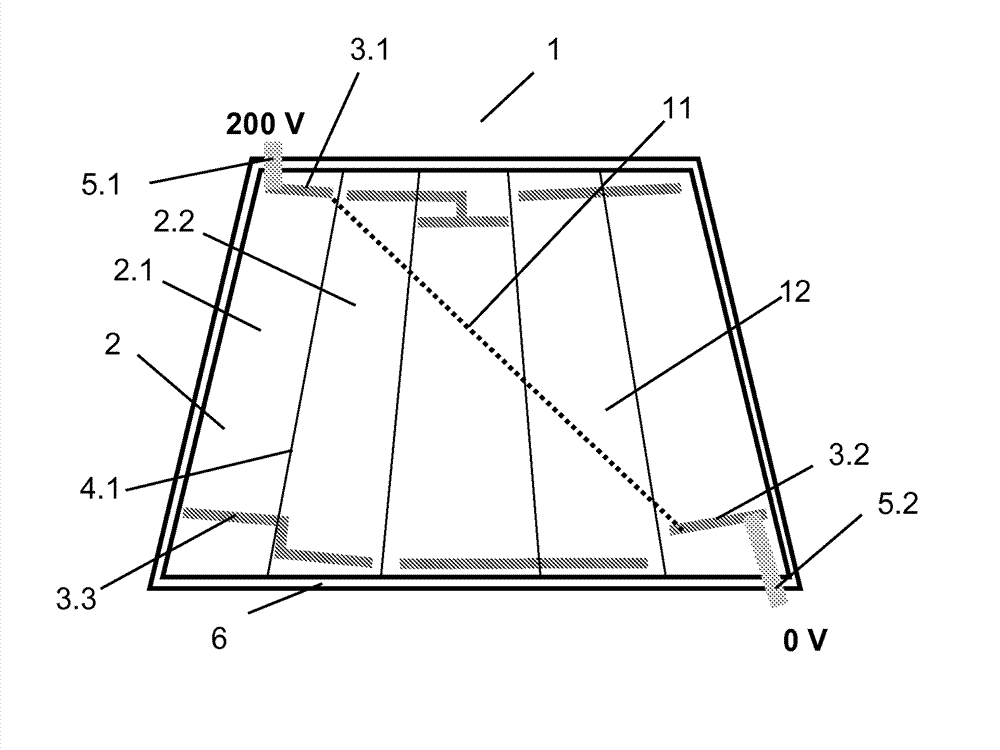

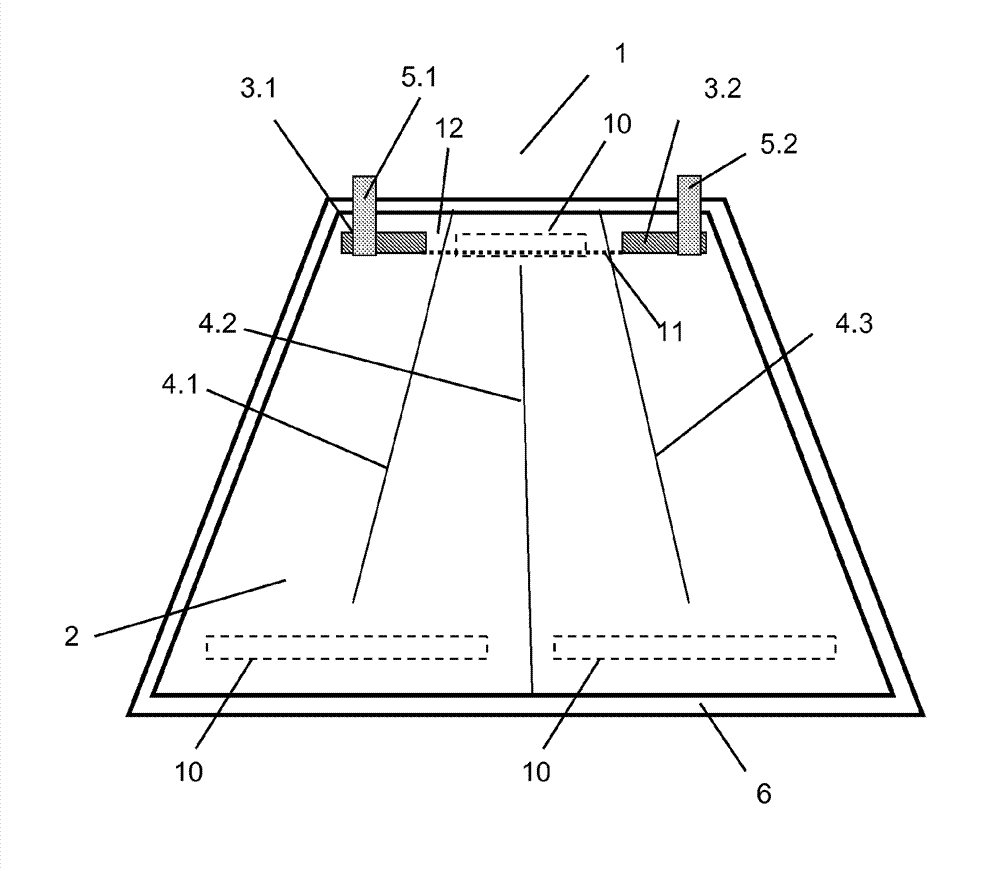

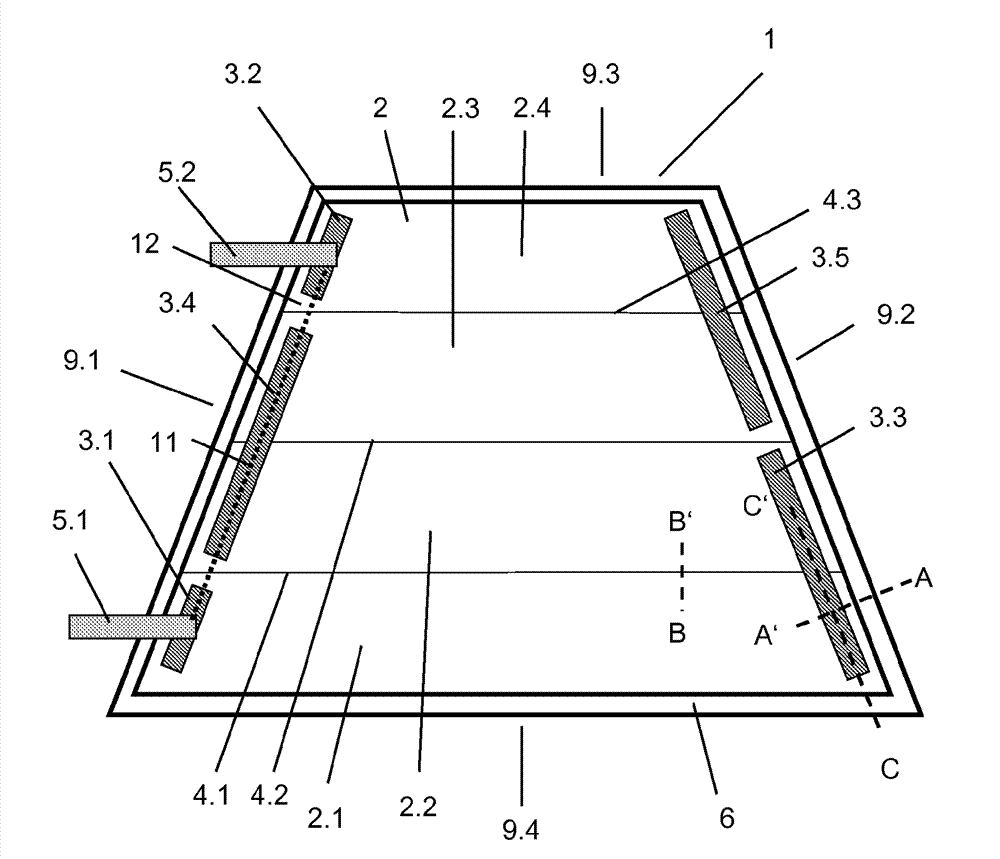

[0047] An embodiment of a composite window according to the invention with an electrically heatable coating is shown in the drawings, which is generally designated by the reference numeral 1 . figure 1 A composite window 1 designed according to the invention in the form of a motor vehicle windshield is shown in a plan view of the outer side IV of the inner window 1.2. figure 2showing along figure 1 A cross-sectional view of the line A-A'.

[0048] The individual panes 1.1 and 1.2 of the composite pane 1 are made of float glass and have a thickness of 2.1 mm each. The individual windows are interconnected with a thermoplastic interlayer. The thermoplastic interlayer is made of polyvinyl butyral (PVB) foil 7 with a thickness of 0.76 mm. In the example shown, a transparent, electrically conductive coating 2 is applied on the side III of the inner pane 1 . 2 facing the thermoplastic intermediate layer 7 . Instead, the electrically heatable coating can be applied to the side I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com