Dynamic high-pressure microfluidization-enzymolysis method for preparing hypoallergenic beta-lactoglobulin

A high-pressure micro-jet and lactoglobulin technology, which is applied in the field of dairy processing and the production of hypoallergenic β-lactoglobulin, can solve the problems of no β-lactoglobulin products and less statistical reports on milk allergy , to achieve the effect of eliminating allergies, reducing allergies, reducing or allergies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment the present invention is described in further detail:

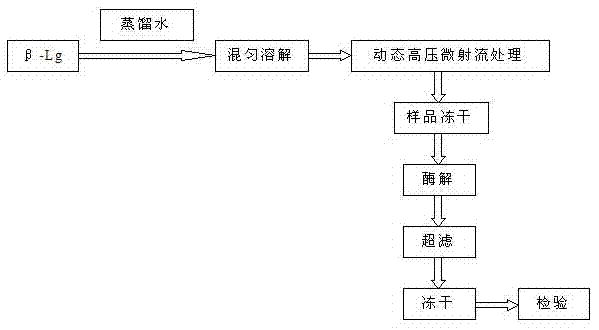

[0018] Weigh 1g of β-lactoglobulin, dissolve it in 1L of secondary deionized water at room temperature, and use a magnetic stirrer to stir at a speed of 50-80rpm for 5-10min to completely dissolve the protein; use a dynamic high-pressure microjet at a pressure of 160MPa The β-lactoglobulin solution was treated 3 times, and the sample was collected for lyophilization; 118.8 mg of the lyophilized β-lactoglobulin sample was dissolved in 10 mL of 50 mM, pH 7.8 and ionic strength of 0.08 M (NaCl) Prepare in Tris buffer; weigh 0.066mg trypsin (10,000U / mg) and dissolve in 5mL Tris buffer of 50mM, pH7.8 and ionic strength 0.08M (NaCl) for use; weigh trypsin inhibitor 110.6 mg was dissolved in 2 mL of 50 mM Tris buffer with pH 7.8 and ionic strength of 0.08 M (NaCl) for use; according to the enzyme-to-substrate ratio of 1:40, 250 μL of trypsin solution was added to 10 mL of β-lactate In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com