Compound protein amino-acid feed

A compound protein and protein feed technology, applied in the field of animal feed, to achieve the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

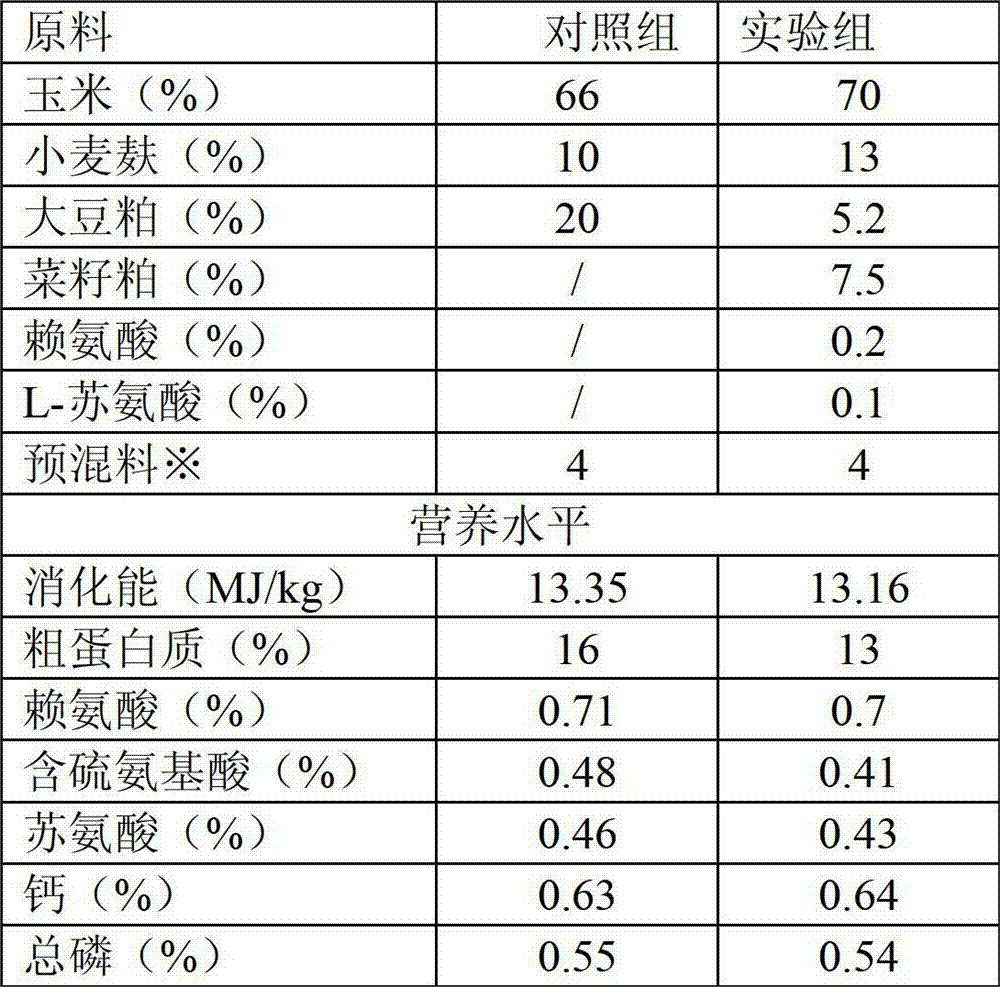

[0012] Embodiment 1, 30kg-60kg growing pig diet experiment

[0013] Experimental design: diets with two protein levels, the control group was a corn-soybean meal type high crude protein diet with a crude protein content of 16%; the experimental group was a low protein diet with a protein content of 13%, balancing sulfur-containing amino acids and Threonine content, see the following table 1 for details:

[0014] Table 1 embodiment 1 two kinds of diet experimental designs

[0015]

[0016] Note: *The content of lysine in the compound premix is 2.5%.

[0017] The preparation process: first crush the soybean meal, and then take part of the crushed soybean meal and carry out step-by-step premixing with lysine and threonine. Then other pulverized soybean meal and rapeseed meal are added into the blender for stirring and mixing, and finally the mixture of soybean meal powder and various amino acids previously premixed step by step is added into the blender. Mix and stir for ...

Embodiment 2

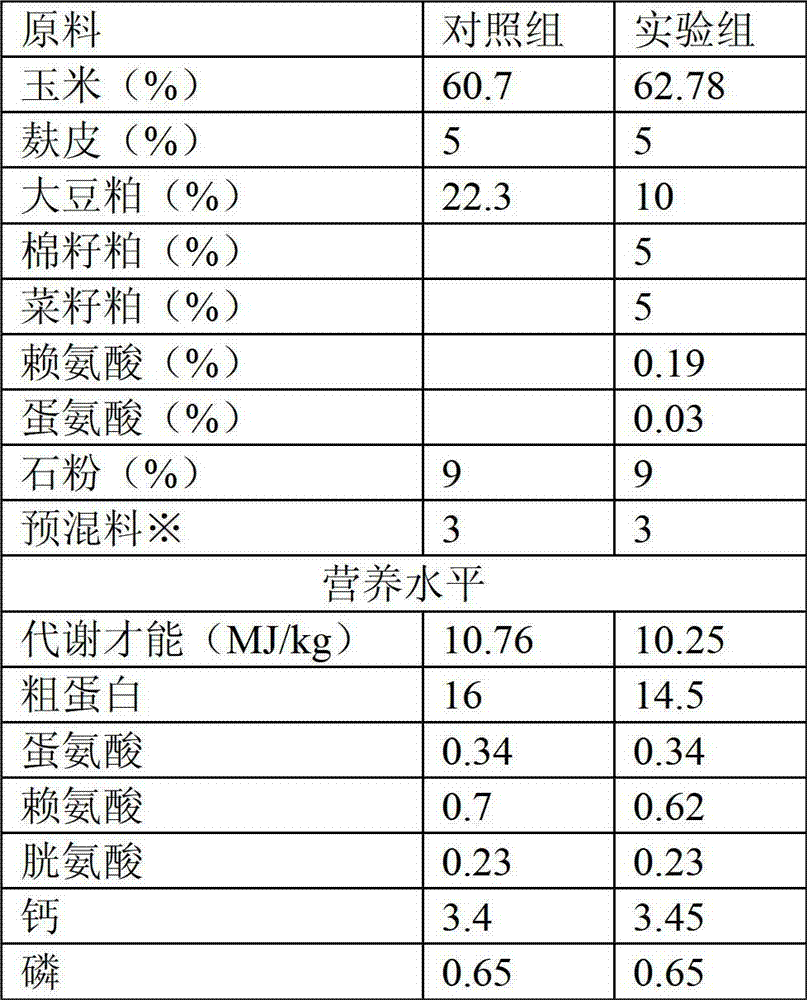

[0019] Example 2: Diet experiment for high-yielding laying hens

[0020] Experimental design: diets with two protein levels, the control group was a corn-soybean meal type high crude protein diet with a crude protein content of 16%; the experimental group was a low protein diet with a protein content of 14.5%, and a balanced lysine content , see Table 2.

[0021] Two kinds of diet experimental design of table 2 embodiment 2

[0022]

[0023] Note: *The premix contains 3.3% methionine.

[0024] The control group is the corn-soybean meal type high crude protein ration based on the total amino acid that has been used in the current laying hen scale farms: the experimental group is the embodiment of the application of the compound protein amino acid of the present invention in the laying hen scale farms, with digestible amino acids as the basis Basic low protein diet. The proportion of amino acids in the compound protein is: 10% soybean meal, 5% cottonseed meal, 5% rapeseed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com