Shearing mechanism of resin-based fiber placement system

A shearing mechanism, resin-based technology, applied in metal processing and other directions, can solve the problems that the fiber belt is easy to fall into the channel, the impact of the entire mechanism, and the short service life of the blade, so as to achieve convenient application, improve reliability, and reduce cutting force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

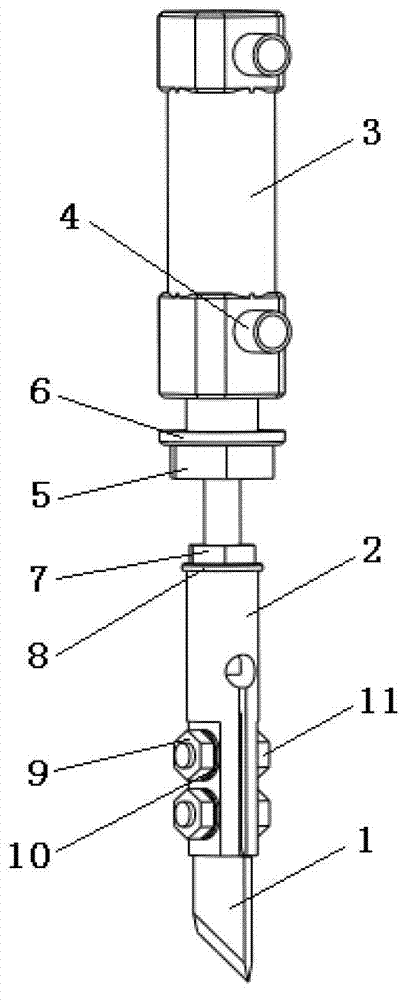

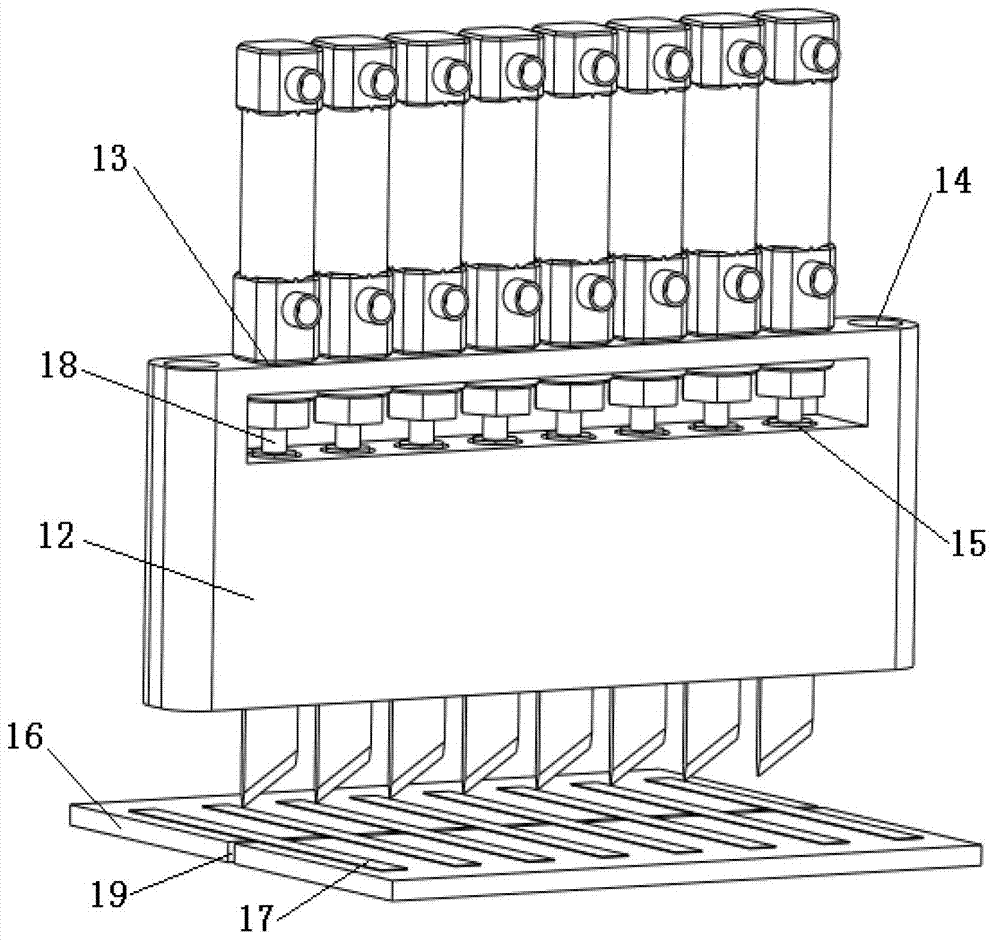

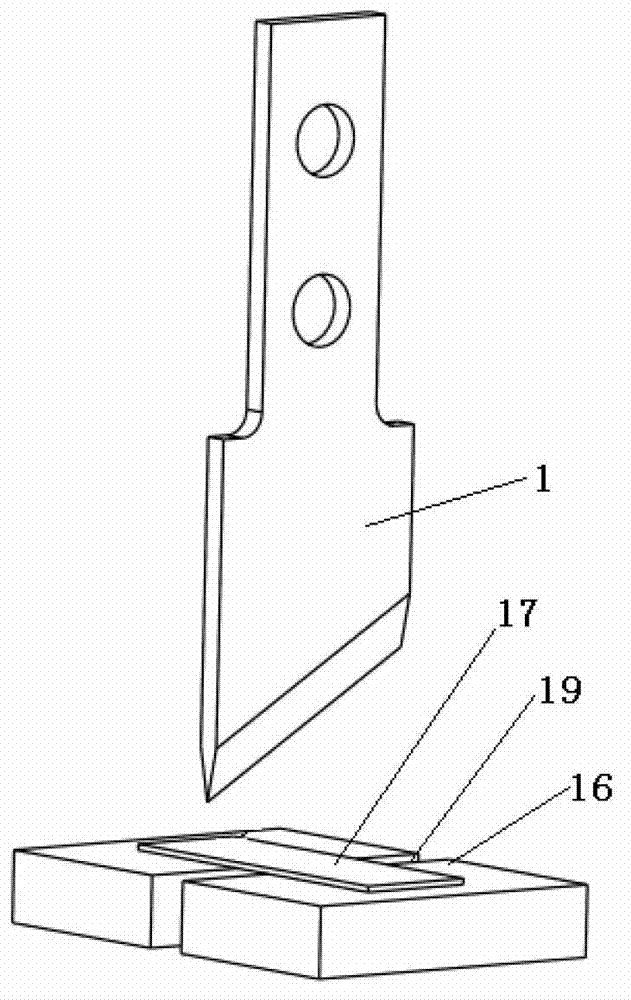

[0025] Such as figure 1 , 2 , 3, 4, and 5 show that the mechanism mainly includes an oblique blade 1, a handle block 2, a cylinder frame 12, an anvil 16, an anvil slit 19 and a driving element cylinder 3 of the device; in this mechanism, the oblique blade 1 The bolt 11, the third spring washer 10, the third nut 9 are connected with the handle block 2, the handle block 2 is connected with the cylinder rod 18 through the second spring washer 8, the second nut 7, and the cylinder 3 is connected by the second spring washer 8 and the second nut 7. A nut 5 and the first spring washer 6 are installed in the first installation hole 13 on the cylinder frame 12, and finally the whole shearing mechanism is integrated in the silk laying head of the silk laying system through the second installation hole 14. please combine image 3 As shown, in the silk laying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com