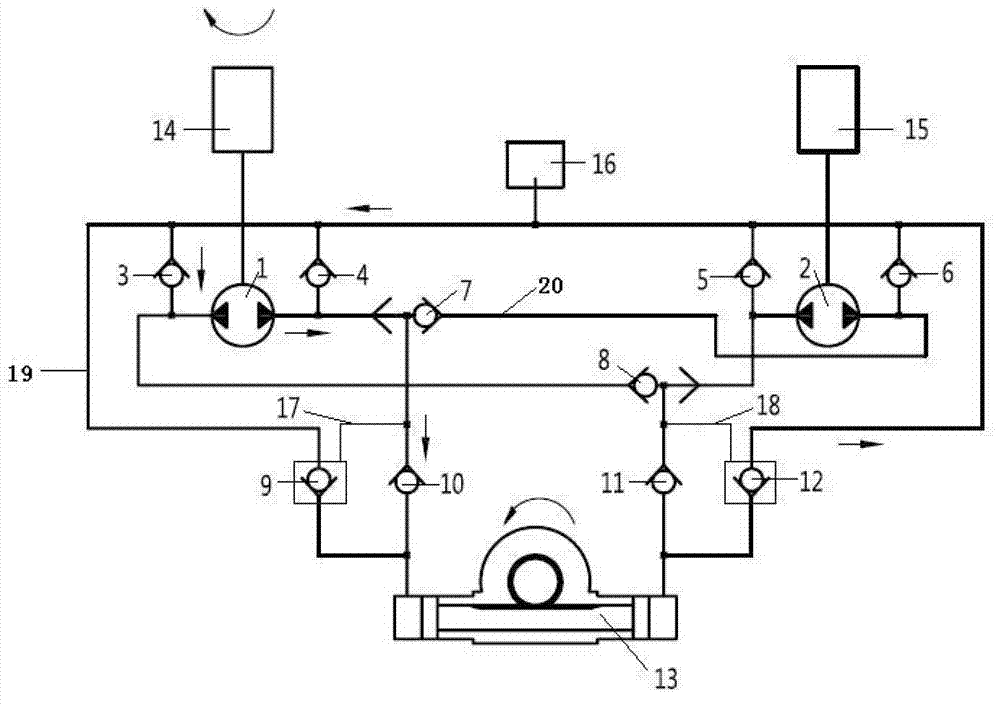

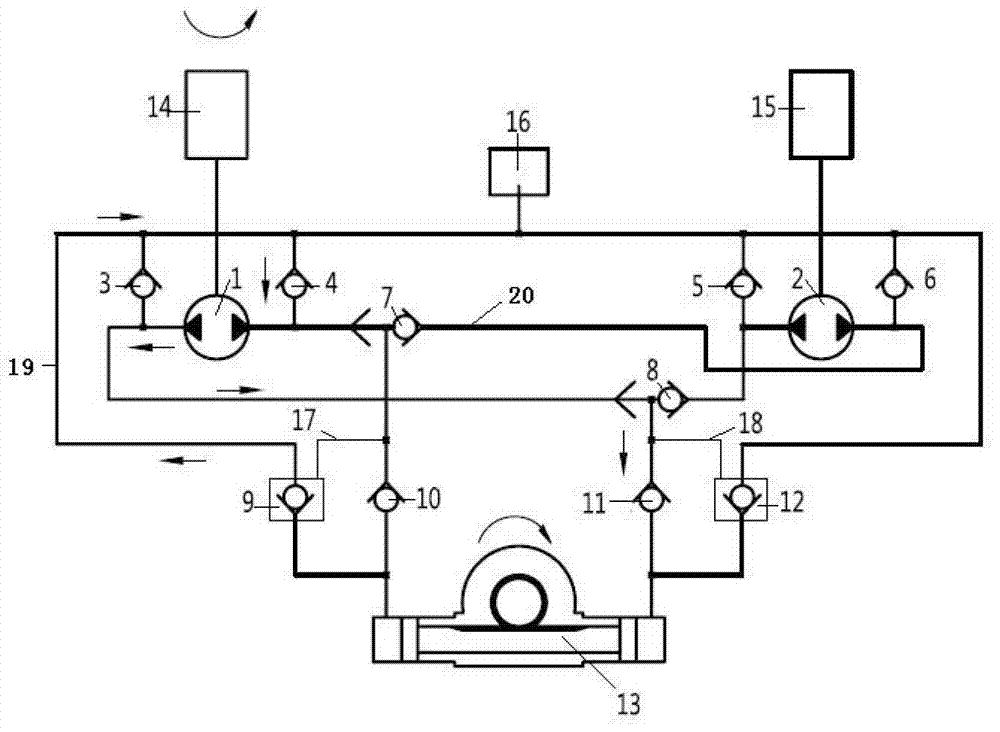

Full-automatic hydraulic bidirectional servo off tracking correction system

A calibration system and fully automatic technology, applied in the field of hydraulic systems, can solve the problems of inconvenient installation, high failure rate, inconvenient installation and maintenance, etc., and achieve the effect of convenient installation and replacement, low failure rate and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A fully automatic hydraulic two-way servo deviation correction system is shown in the figure. The system includes a rack-and-pinion swing cylinder 13, a left two-way pump 1 and a right two-way pump 2. The system is symmetrical about the rack-and-pinion swing cylinder 13 , the left two-way pump 1 and the right two-way pump 2 are symmetrically distributed, and the left friction wheel 14 and the right friction wheel 15 are arranged on the left two-way pump 1 and the right two-way pump 2, and the left cavity of the rack and pinion swing oil cylinder 13 along the Connect the first pipeline 19 to the right chamber in turn to connect the left end to control the one-way valve 9, the oil tank 16 and the right end to control the one-way valve 9, and through the second pipeline 20 to connect the right shuttle valve 8, The right two-way pump 2 and the left shuttle valve 7, the left hydraulic control pipeline 17 and the left first one-way valve 10 are connected between the left shutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com