A kind of sculpture cement preparation device for arts and crafts

A preparation device and technology for arts and crafts, which is applied in the field of sculpture cement preparation devices for arts and crafts, can solve problems such as low adhesion, easy mildew, and easy cracking of large sculptures, and achieve the effect of convenient operation and use, and high automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

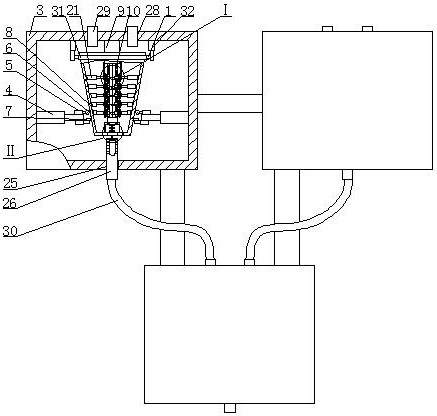

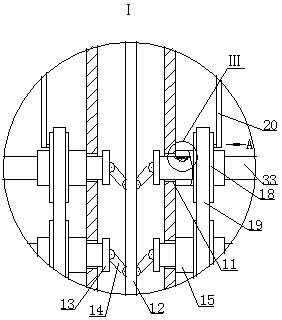

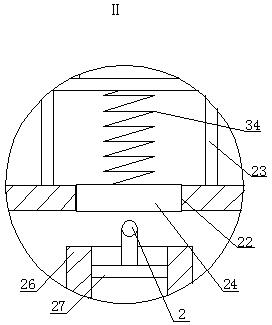

Image

Examples

Embodiment 1

[0020] Embodiment one: 80 parts of carboxymethyl cellulose CMC, 95 parts of carboxymethyl cellulose CMS, 10 parts of dioctyl isophthalate, 50 parts of glycerol, 2.8 parts of sodium benzoate, 100 parts of light calcium carbonate, carbonic acid Magnesium 60 parts, talcum powder 225 parts, titanium dioxide 120 parts, purified water 370 parts. The sculpture cement is preferably made of the raw materials in this weight part, and the prepared sculpture cement has the advantages of uniform color, slight fragrance, good adhesion, and no pollution.

Embodiment 2

[0021] Embodiment two: 95 parts of carboxymethyl cellulose CMC, 80 parts of carboxymethyl cellulose CMS, 7 parts of dioctyl isophthalate, 60 parts of glycerol, 0.6 part of sodium benzoate, 120 parts of light sodium calcium carbonate, carbonic acid Magnesium 80 parts, talcum powder 120 parts, titanium dioxide 130 parts, purified water 390 parts. The sculpture clay is preferably made of the raw materials of this weight part. The prepared sculpture clay has uniform color, slight fragrance, extremely low toxicity, less impurities, cold resistance (-17 ° 2 hours), heat resistance (45 ° 2 hours), etc. advantage.

Embodiment 3

[0022] Embodiment three: 110 parts of carboxymethyl cellulose CMC, 110 parts of carboxymethyl cellulose CMS, 4 parts of dioctyl isophthalate, 40 parts of glycerol, 5 parts of sodium benzoate, 110 parts of light sodium calcium carbonate, carbonic acid Magnesium 70 parts, talcum powder 130 parts, titanium dioxide 225 parts, purified water 350 parts. The sculpture cement is preferably made of the raw materials of this weight part. The prepared sculpture cement has extremely low toxicity, less impurities, cold resistance (-17 ° 2 hours), heat resistance (45 ° 2 hours), good adhesion, and no pollution And other advantages, the arts and crafts sculptures made of this clay are not afraid of wind and rain, and are not easy to crack and deform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com