Liquid fuel gasification device and liquid fuel burner

A liquid fuel and gasification device technology, which is applied in the direction of burners, combustion methods, combustion types, etc., to achieve the effects of increased gasification, good combustion effect, and reduced carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0024] First, the specific implementation of the liquid fuel gasification device of the present invention will be described in detail.

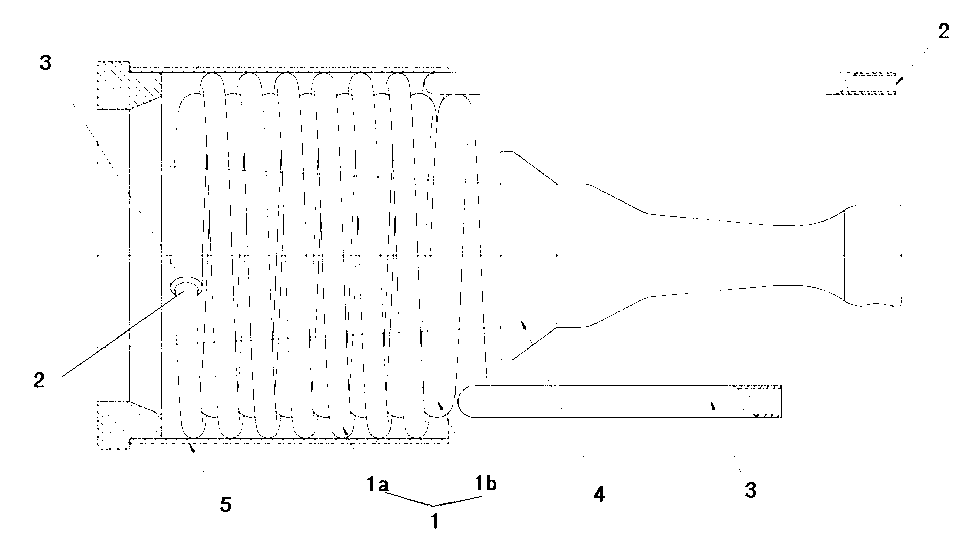

[0025] Such as figure 1 Shown is a schematic structural diagram of an embodiment of a liquid fuel gasification device of the present invention. The liquid fuel gasification device of this embodiment includes at least two layers of spiral gasification coils 1 stacked together. Each layer of spiral gasification coil 1 is provided with a fuel inlet 2 and a fuel outlet 3, two adjacent to each other. In the spiral gasification coil 1, the fuel outlet 3 of the spiral gasification coil 1 in the outer layer is connected to the fuel inlet 2 of the spiral gasification coil 1 in the inner layer, and the spiral gasification coil in the innermost layer The center of the tube 1 is provided with a heat source 4 for gasifying liquid fuel, the fuel inlet 2 of the spiral gasification coil 1 located in the outermost layer is connected to the liquid fuel storage de...

no. 2 example

[0031] The specific implementation of the liquid fuel burner of the present invention will be described in detail below.

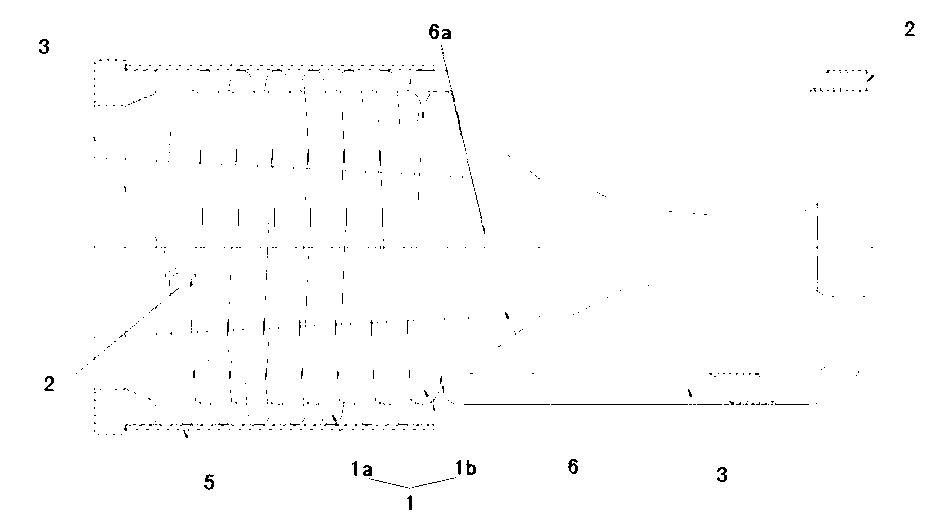

[0032] Such as figure 2 Shown is a schematic structural diagram of an embodiment of a liquid fuel burner of the present invention. The liquid fuel burner of this embodiment includes the liquid fuel gasification device and the combustion device 6 described in the first embodiment. The fuel inlet of the combustion device 6 is connected to the fuel outlet 3 of the spiral gasification coil 1 located in the innermost layer. That is, the fuel inlet of the combustion device 6 of this embodiment is connected to the fuel outlet 3 of the inner spiral gasification coil 1b.

[0033] The liquid fuel burner of this embodiment adopts the liquid fuel gasification device of the first embodiment, which can fully gasify the liquid fuel and can prevent the problem of carbon clogging, that is, realize the liquid gasification and combustion of the liquid fuel burner. It has the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com