Liquid fuel gasification device and burner

A liquid fuel, gasification device technology, applied in the burner, combustion method, combustion type, etc., to achieve good combustion effect, high combustion efficiency, and reduce carbon precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0024] First, the specific implementation of the liquid fuel gasification device of the present invention will be described in detail.

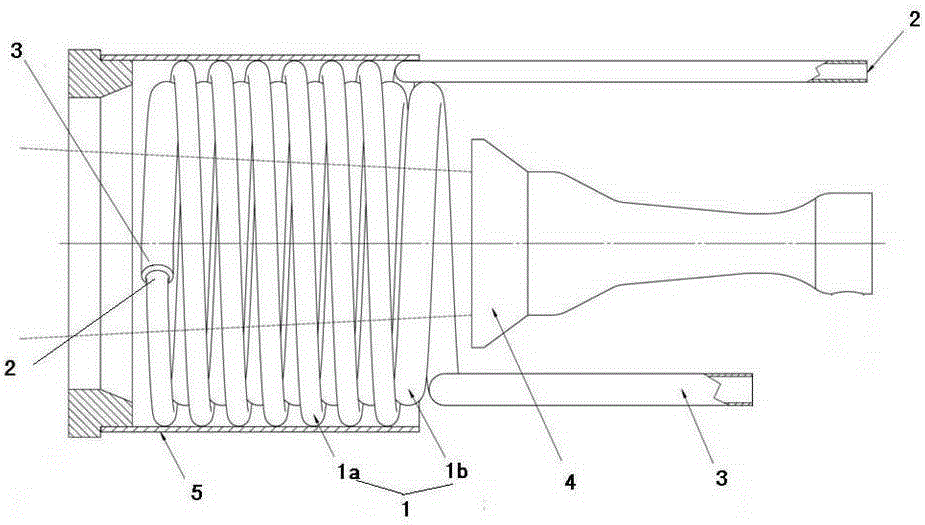

[0025] Such as figure 1 Shown is a schematic structural diagram of an embodiment of the liquid fuel gasification device of the present invention. The liquid fuel gasification device of this embodiment includes at least two layers of spiral gasification coils 1 stacked together, each layer of spiral gasification coils 1 is provided with a fuel inlet 2 and a fuel outlet 3, adjacent to each other In the layered spiral gasification coil 1, the fuel outlet 3 of the outer spiral gasification coil 1 is connected to the fuel inlet 2 of the inner spiral gasification coil 1, and the innermost spiral gasification coil The center of the tube 1 is provided with a heat source 4 for vaporizing liquid fuel, the fuel inlet 2 of the outermost spiral gasification coil 1 is externally connected to the liquid fuel storage device, and the fuel outlet of the inner...

no. 2 example

[0031] The specific implementation of the liquid fuel burner of the present invention will be described in detail below.

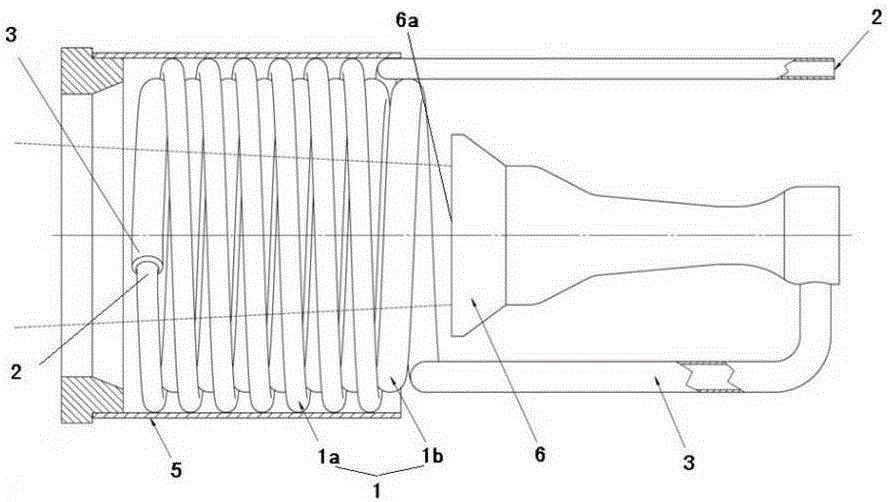

[0032] Such as figure 2 Shown is a schematic structural view of an embodiment of the liquid fuel burner of the present invention. The liquid fuel burner of this embodiment includes the liquid fuel gasification device and the combustion device 6 described in the first embodiment, the fuel inlet of the combustion device 6 is connected with the fuel outlet 3 of the spiral gasification coil 1 located in the innermost layer , that is, the fuel inlet of the combustion device 6 of this embodiment is connected with the fuel outlet 3 of the inner spiral gasification coil 1b.

[0033] The liquid fuel burner of this embodiment, by adopting the liquid fuel gasification device of the first embodiment, can fully gasify the liquid fuel, and can prevent the problem of carbon clogging, that is, realize the liquid gasification combustion of the liquid fuel burner, The ut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com