Full-flow-point rapid detection device for water meter

A detection device and full flow technology, applied in the direction of measuring device, test/calibration device, liquid/fluid solid measurement, etc., can solve the problems of low production efficiency, inability to adjust the water meter in real time with the serial detection device, and fail to solve the problem of quick test of flow point and other issues, to achieve the effect of improving calibration accuracy and production efficiency, and improving sampling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

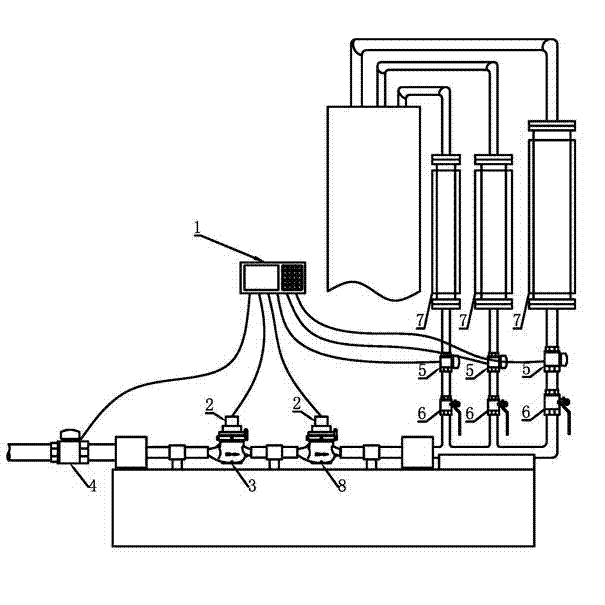

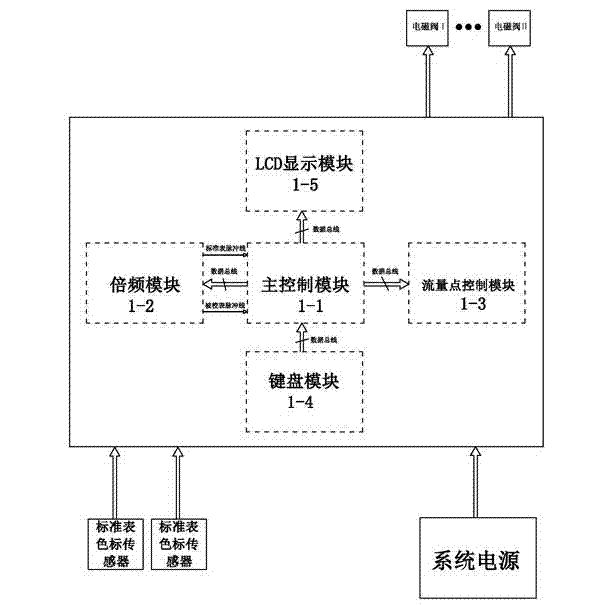

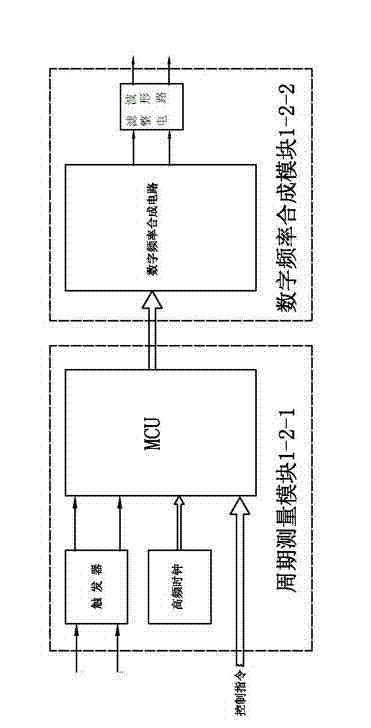

[0013] A rapid detection device for full flow point of a water meter includes an embedded controller and a detection system. The detection system includes a water inlet pipe and a water outlet pipe. A standard water meter and a calibrated water meter are sequentially installed on the pipeline between the water inlet pipe and the calibrated water meter. It is a color mark sensor with a pulse signal, and the solenoid valve Ⅰ which can control the opening or closing of the meter calibration water source is installed at the water inlet pipe, and the solenoid valve Ⅱ which realizes the switching of the flow point is installed at the water outlet pipe; the embedded controller includes a The frequency multiplication module that multiplies the pulse input by the color mark sensor, the flow point control module that can realize the automatic switching of each flow point, the keyboard module that can receive the operator's input parameters and instructions, the LCD display module that ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com