Circuit board mark detection and offset detection method and arrangement method

A circuit board and offset technology, applied in the field of mark detection and offset detection, can solve the problems of bad sub-board detection, long idle time, etc., and achieve the effect of shortening the output time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

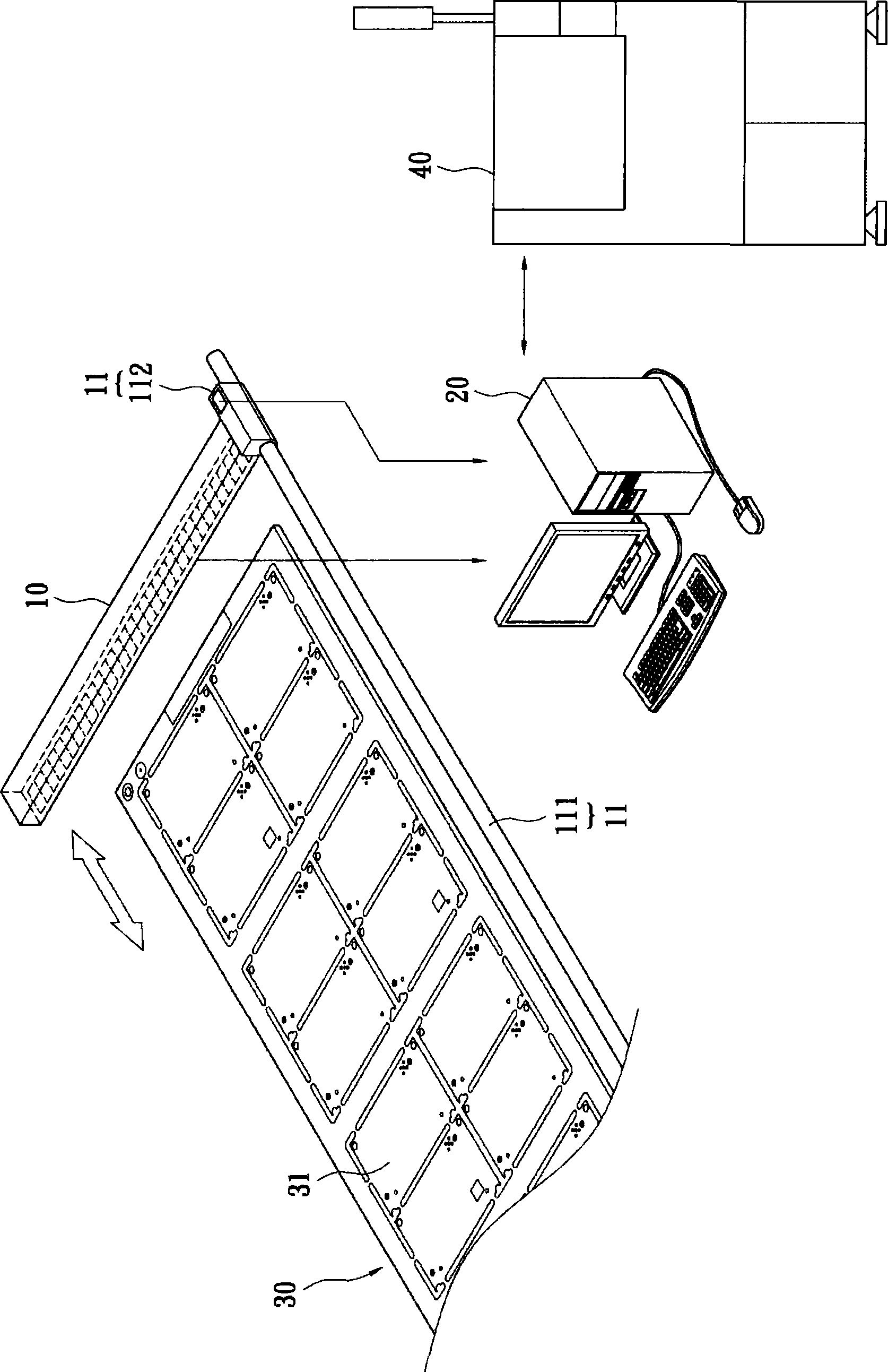

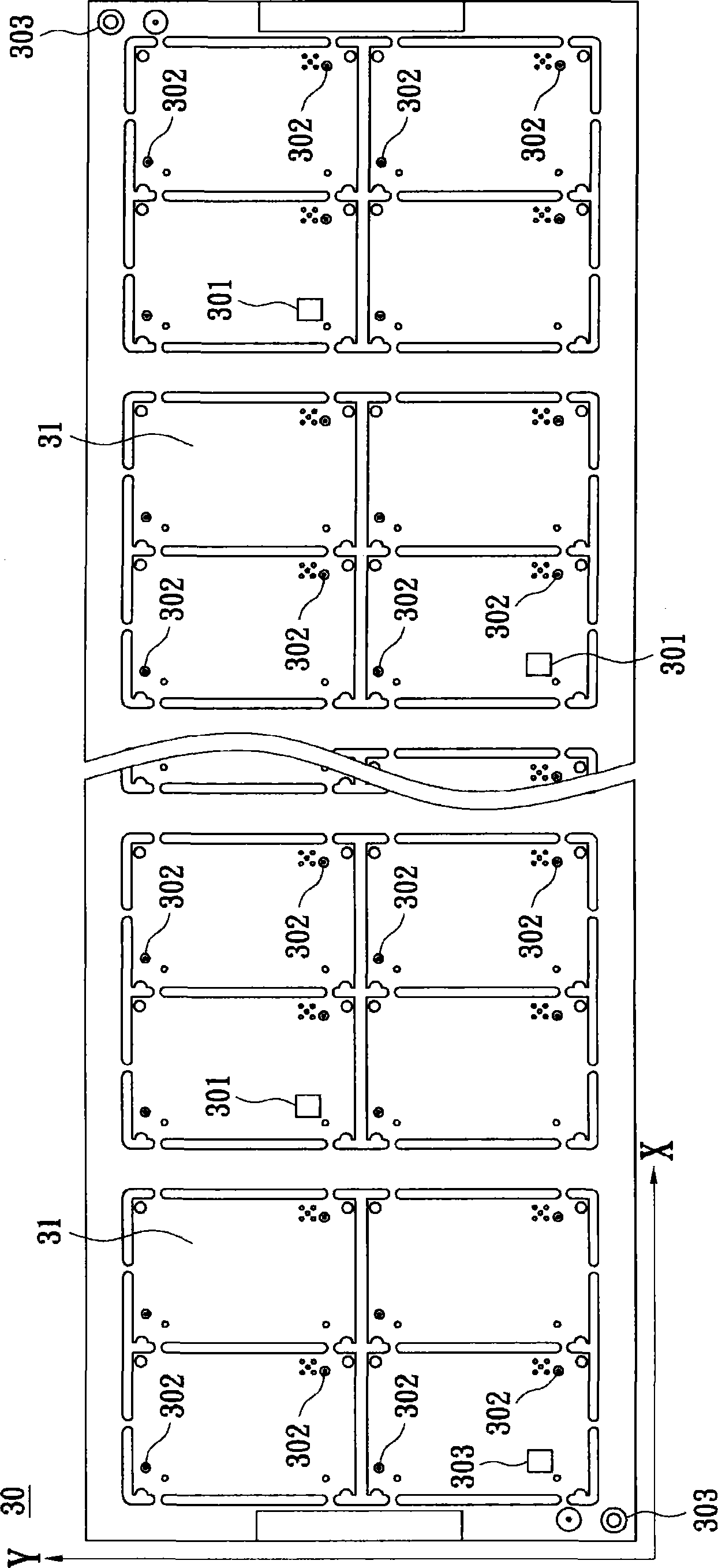

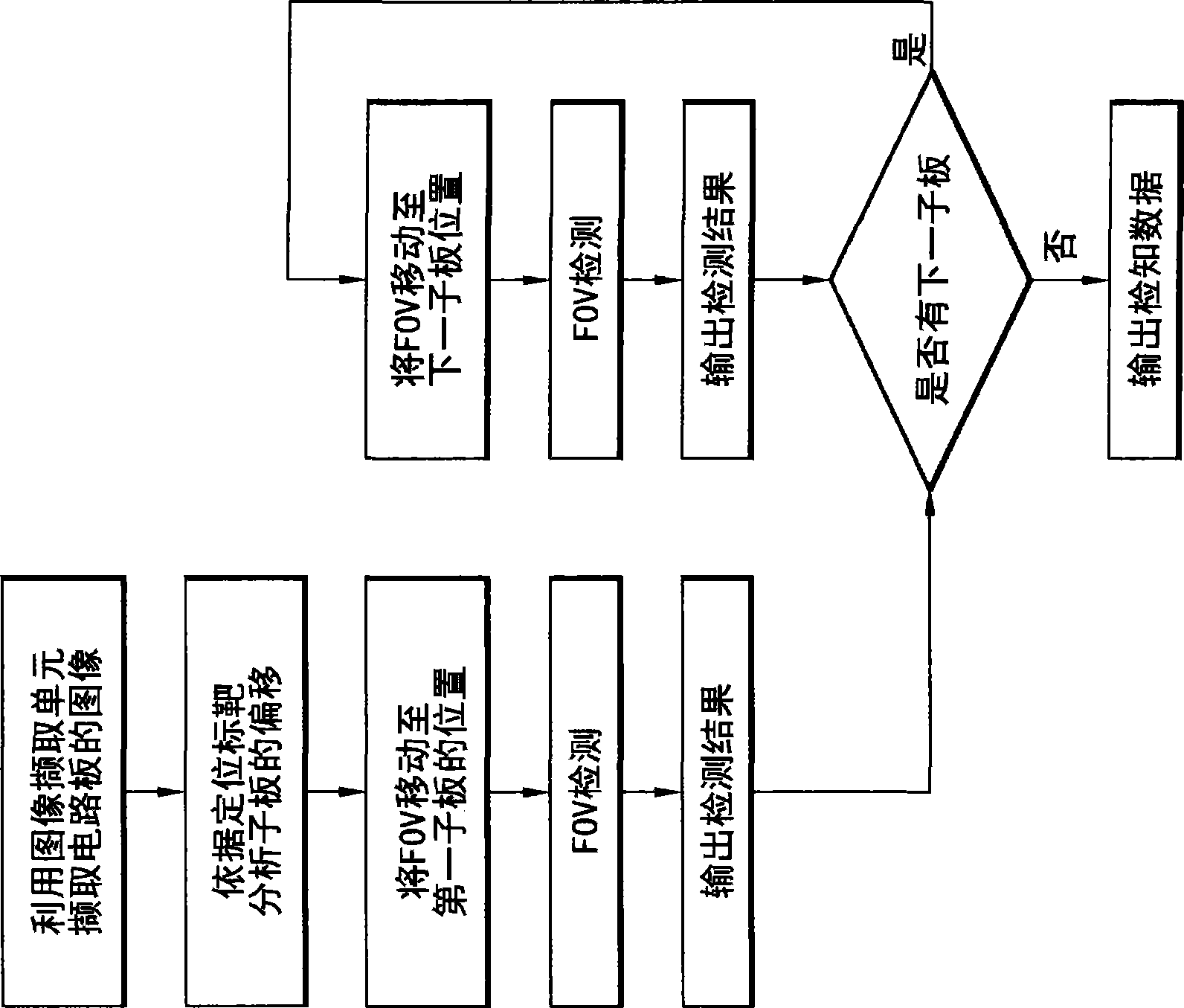

[0022] The present invention is to provide a detection device independent of the component mounting machine upstream of the component mounting machine (such as the pick-and-place machine, flip-up component machine: Flip Chip Mounter), which is used to quickly and independently detect the circuit Bad marks or / and local fiducial marks on multiple sub-boards on the board, and passed to the downstream pick-and-place machine, so that the subsequent part-placement steps can be based on the detection device of the mark The obtained detection data is placed on the sub-boards belonging to good products, so that the standby time of the pick-and-place machine (including film feeding, film output, target detection time and detection time of defective product marks) is greatly shortened, It is not necessary to perform this detection operation on the part placement machine, thereby increasing the productivity of the overall production line. Moreover, the detection device of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com