Formation method of high-capacity power lithium iron phosphate battery

A lithium iron phosphate battery and the technology of its formation method are applied in the directions of non-aqueous electrolyte storage batteries, electrolyte storage batteries, charging/discharging of secondary batteries, etc. The film is not dense and complete enough to achieve the effect of improving the number of charge and discharge and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

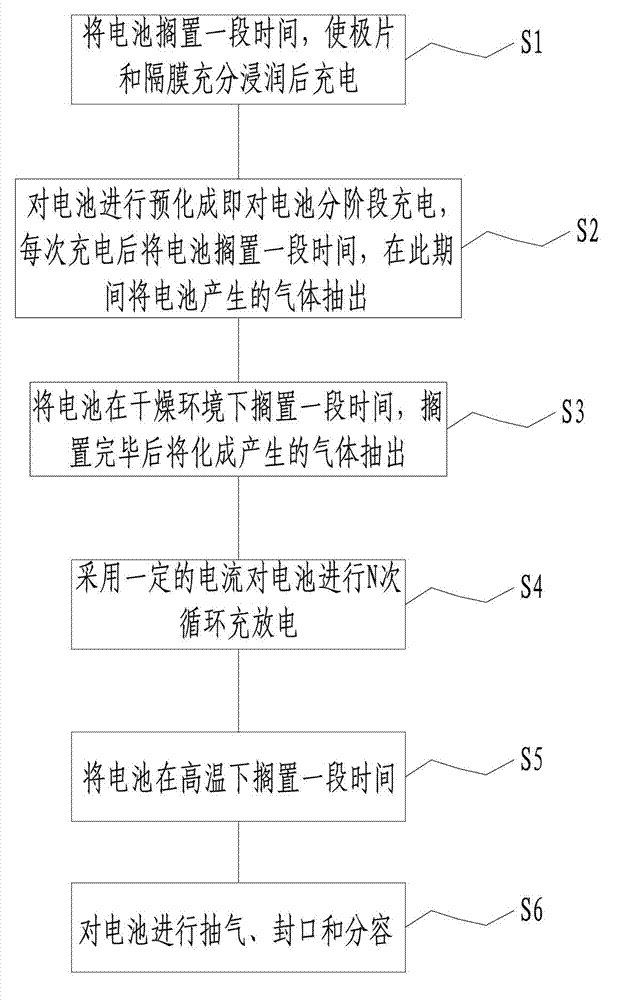

[0029] Such as figure 1 As shown, the present invention provides a method for forming a large-capacity lithium iron phosphate battery, comprising the following steps:

[0030] Step A: Put the electrolyte in the battery and leave it at room temperature for a period of time T, and start charging after the pole pieces and diaphragm are fully infiltrated;

[0031] Step B: Use a certain current A and power to preform the battery in stages, divide the preformation of the battery into N stages for charging according to the different battery capacities, and put it aside for a period of time T1 after each charge, and at the same time put it aside During the process, the gas inside the battery is pumped out;

[0032] Step C: After the preformation stage is completed, the battery is placed in a dry environme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com