Pu'er tea pressing steam-pressure machine and tea pressing method

A technology for Pu-erh tea and pressed tea, which is used in tea processing before extraction, food forming, food science, etc., can solve the problem that the product shape and specifications do not have uniformity, continuity, product quality stability changes, and Pu-erh tea is not easy to control. and other problems, to achieve the effect of shortening labor time, reducing human processing errors, and beautiful products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described;

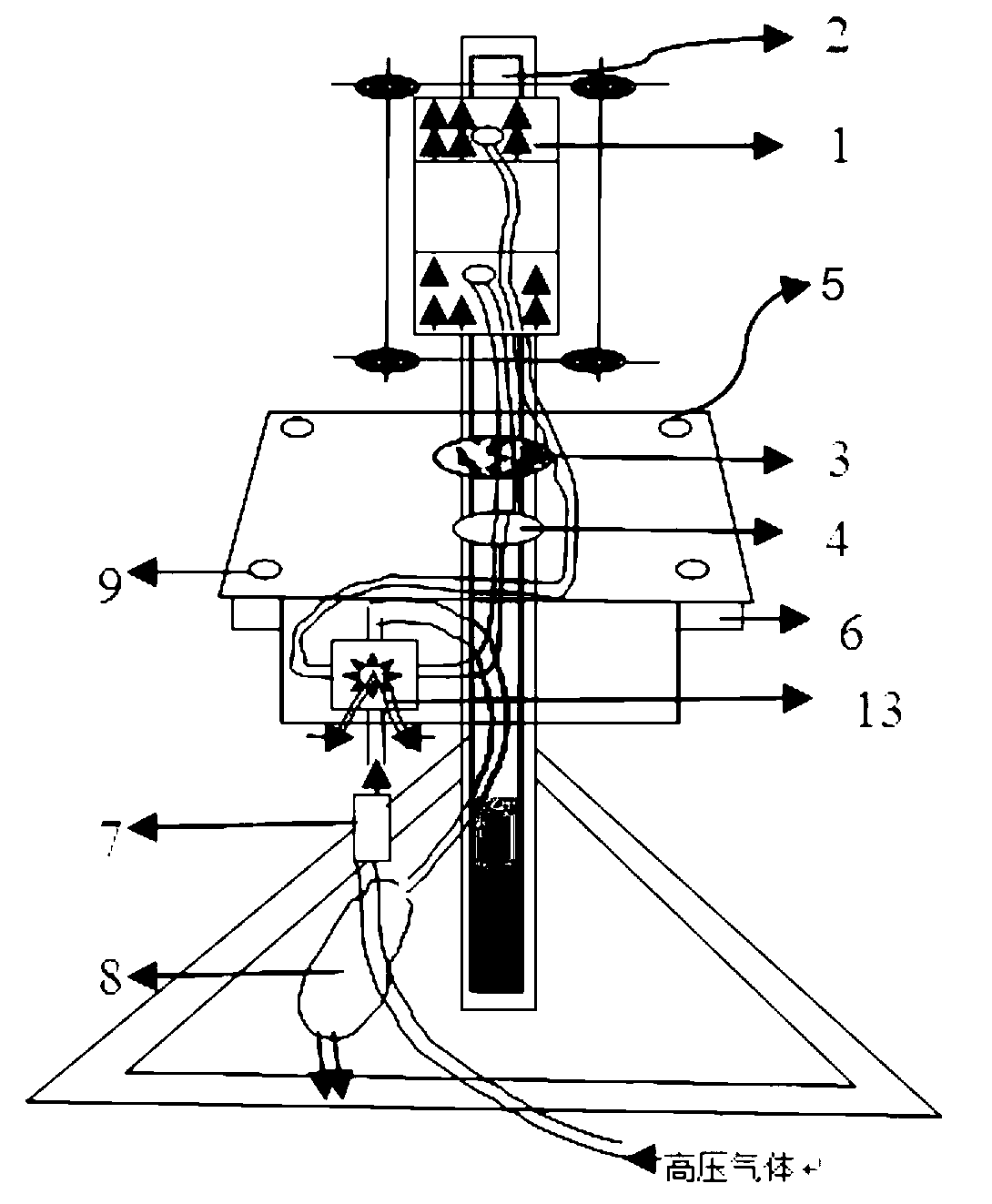

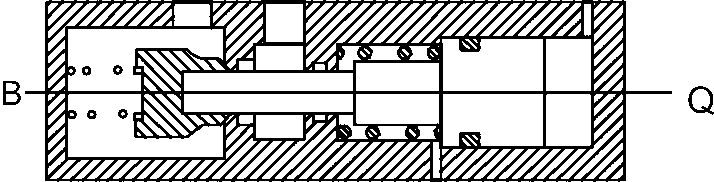

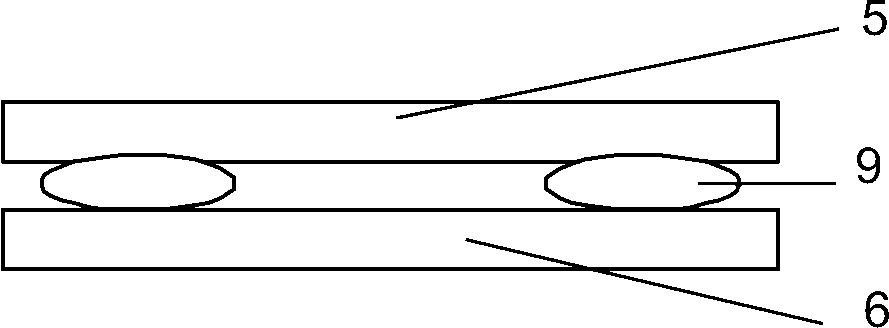

[0027] Such as figure 1 , 2 Shown: a steam press for tea pressing, including: cylinder 1, gantry frame 2, force-bearing round cake 3, adjustable mold 4, tea pressing panel 5, buffer panel 6, one-way valve 7, muffler 8 and manual switch 13. Adjustable mold 4 is placed flat on the tea pressing panel 5, and cylinder 1 is fixed upside down on the gantry 2, and the whole tea pressing steam compressor works by manual switch 13 to control air intake and air discharge. The material of the cake-shaped mold fixed by the tea press in the press tea steam press is made of stainless steel. The working principle is that the buffer panel 6 under the press tea panel 5 and the cylinder 1 work together to neutralize the pressure generated by the pressure, and the extrusion force is reversed. Chong effect. The air supply pipe and the air outlet pipe of the cylinder 1 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com