Device and method of restraining torsional vibration of high-speed rolling mill based on lubricating of rolled interface and method

A high-speed rolling mill and interface lubrication technology, which is applied to the driving device of metal rolling mills, metal rolling, metal rolling, etc., to suppress the torsional vibration of high-speed rolling mills, reduce the sudden frequency of production accidents, and have a simple structure and composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

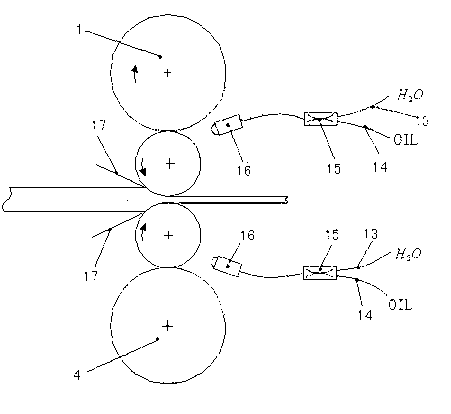

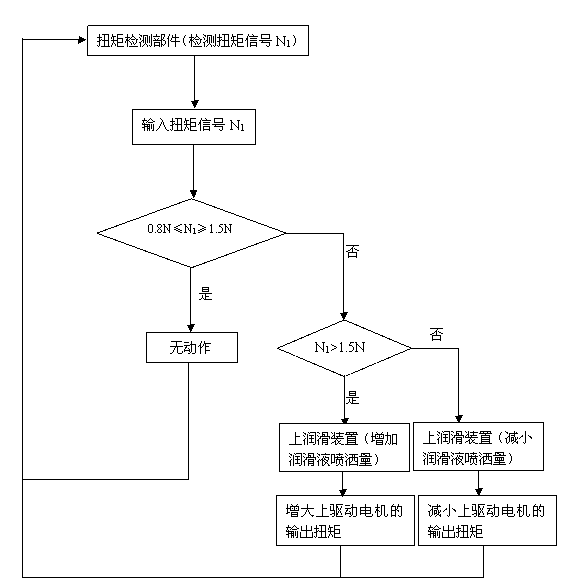

[0021] A device and method for suppressing torsional vibration of a high-speed rolling mill based on rolling interface lubrication, such as figure 1 As shown, the device mainly includes: rolling mill equipment, power transmission system, lubrication device, signal acquisition and processing device. Among them, the power transmission equipment is connected with the rolling mill equipment through the reduction box, the coupling, and provides power for the rolling of the high-speed rolling mill; the lubrication device is installed on the rolling mill equipment to meet the state of the lubricating oil film required for the rolling process at the rolling interface and to play a role The role of the cooling roll; the signal acquisition and processing device is installed on the components of the rolling mill power transmission system.

[0022] Such as figure 1 As shown, the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com