Welding method for lengthening H-shaped steel of railway freight platform wagon chassis

A technology of railway freight and welding methods, which is applied in welding equipment, arc welding equipment, workpiece edge parts, etc., can solve the problems of complicated welding process, poor welding performance of welding joint length, etc., and achieve reduction of manufacturing cost, material saving, and butt weld seam Quality and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the drawings and embodiments.

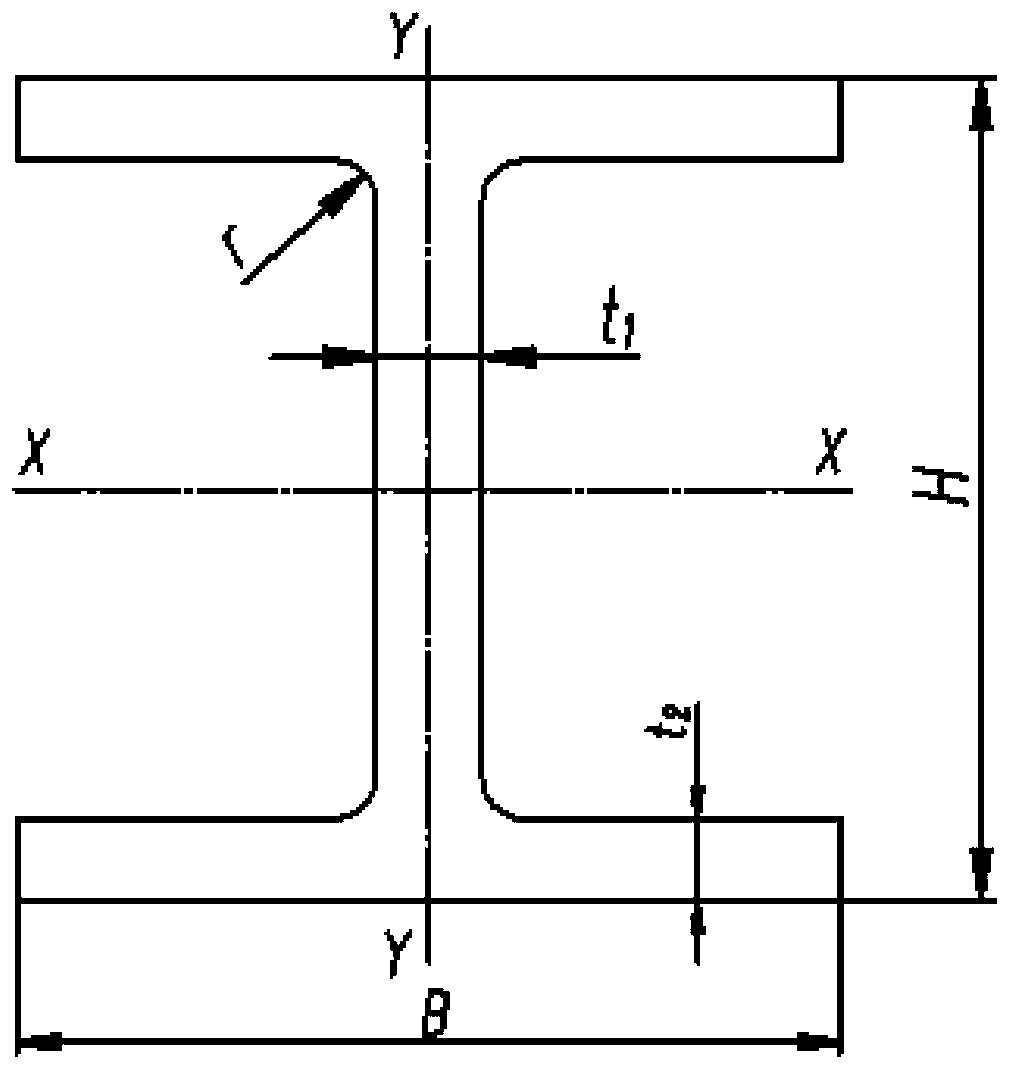

[0021] In order to meet product design requirements, reduce manufacturing costs, and ensure the quality of extension welding, the present invention provides a welding method for H-shaped steel extension for the underframe of a railway freight flat car. , The side beams are welded with rigid extensions, including the following steps:

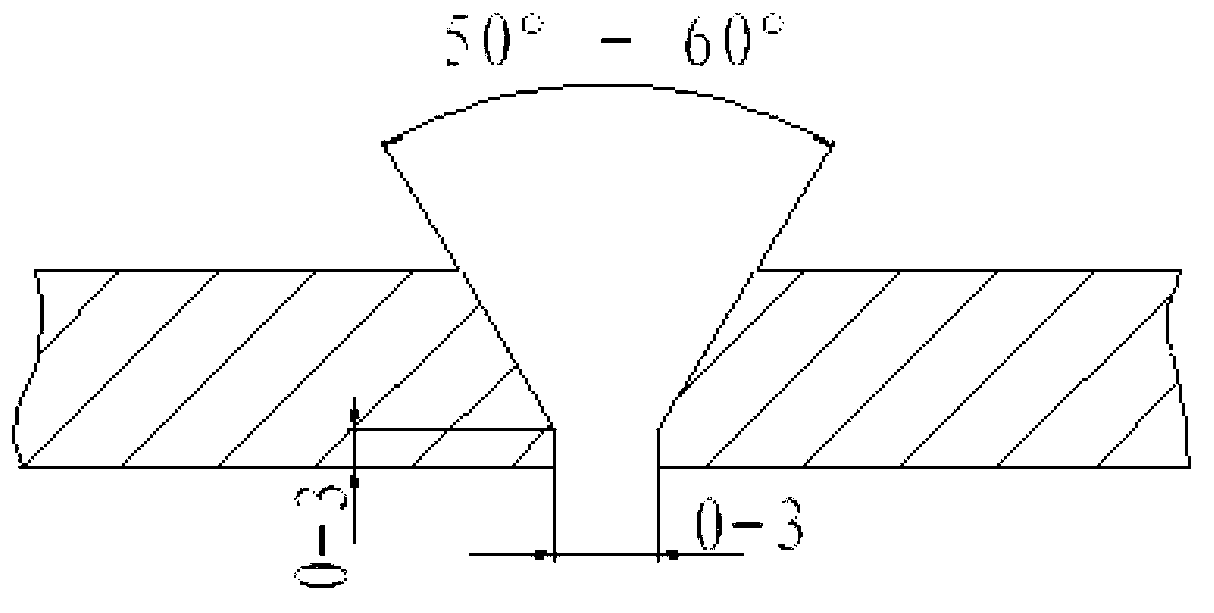

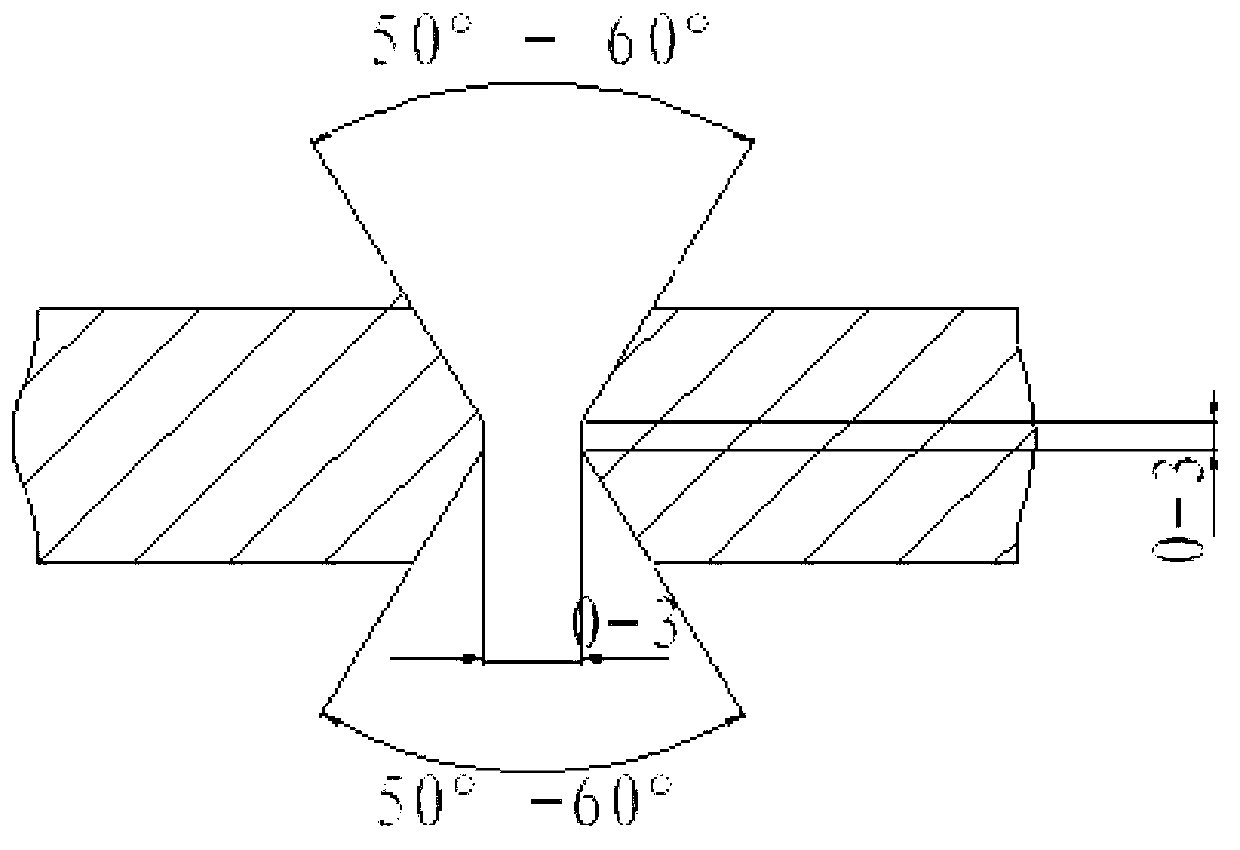

[0022] 1) Such as figure 2 , image 3 As shown, according to the preset length requirements of the H-shaped center beam or side beam of the railway freight flat car, the H-shaped steel is cut according to the preset length, and the H-shaped steel web and wing surface are provided with blunt edges for extension. Groove

[0023] Among them, the groove on the web is V-shaped (such as figure 2 As shown), the groove on the wing surface is X-shaped (such as image 3 As shown), the groove angles of the V-shaped and X-shaped grooves are both 50°~6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com