Method for preparing PDMS chip including both square and arc-shaped channel

A curved channel and square technology, which is applied in the field of microfluidic chip preparation, can solve problems such as complex process steps, stagnation of synthetic materials, and large differences in geometric configuration, and achieve the effect of simple and fast process and controllable arc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

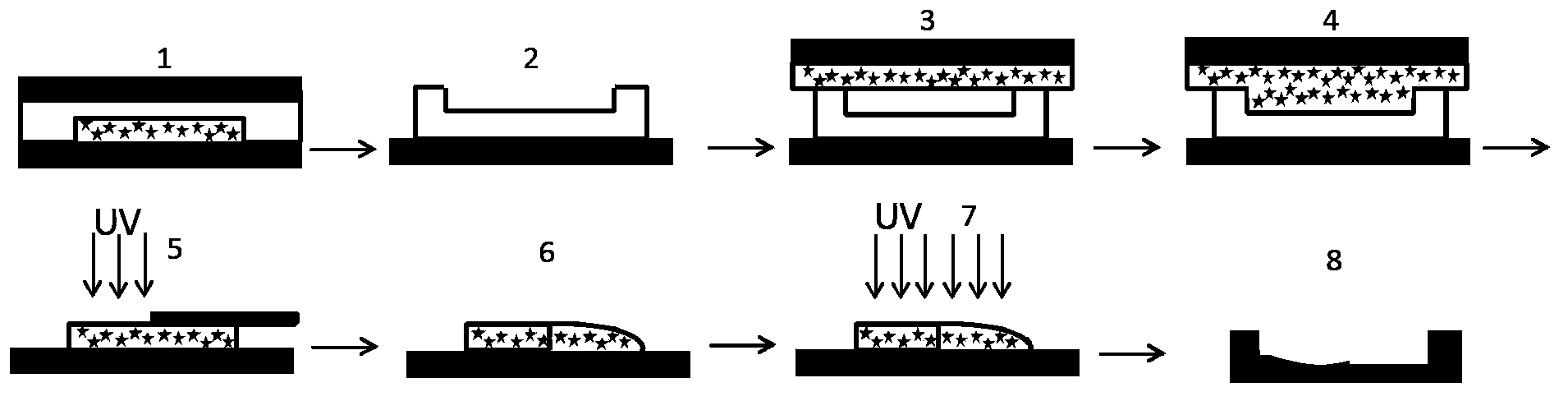

[0026] as per figure 1 The steps shown further illustrate the implementation steps and substantive features of the method:

[0027] (1) A cross-linked SU-8 positive mold containing microchannel patterns was prepared by standard photolithography, and the microprotrusions contained were rectangular squares;

[0028] (2) Preparation of female PDMS: Clamp the cross-linked SU-8 male mold with a certain thickness of liquid PDMS. After the PDMS is cured, the female PDMS with the positive mold pattern reversed is obtained after the PDMS is opened, and the female PDMS is attached. On the glass sheet and silanized to facilitate subsequent demoulding;

[0029] (3) Preparation of uncrosslinked SU-8 positive mold: 150 micron thick solid uncrosslinked SU-8 photoresist removes air bubbles in advance, and clamps it with the PDMS female mold attached to the glass plate and puts it in a vacuum In the oven, after the inside of the oven is evacuated, the temperature is raised to 100°C and maint...

Embodiment 2

[0034] as per figure 1 In the steps shown, the liquid circuit layer in the chip integrated with the microvalve structure is prepared.

[0035] (1) A cross-linked SU-8 positive mold containing microchannel patterns was prepared by standard photolithography, and the microprotrusions contained were rectangular squares;

[0036] (2) Preparation of female PDMS: Clamp the cross-linked SU-8 male mold with a certain thickness of liquid PDMS. After the PDMS is cured, the female PDMS with the positive mold pattern reversed is obtained after the PDMS is opened, and the female PDMS is attached. On the glass sheet and silanized to facilitate subsequent demoulding;

[0037] (3) Preparation of uncrosslinked SU-8 positive mold: 150 micron thick solid uncrosslinked SU-8 photoresist removes air bubbles in advance, and clamps it with the PDMS female mold attached to the glass plate and puts it in a vacuum In the oven, after the inside of the oven is evacuated, the temperature is raised to 100°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com