Modified vegetable protein adhesive and preparation method thereof

A plant protein and adhesive technology, which is applied in the preparation of protein adhesives, animal glue or gelatin, adhesives, etc., can solve the problems of no improvement in flow performance, wood degradation and discoloration, and short service life of products, and it is easy to achieve the quality of finished products The effect of control, fast curing speed and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

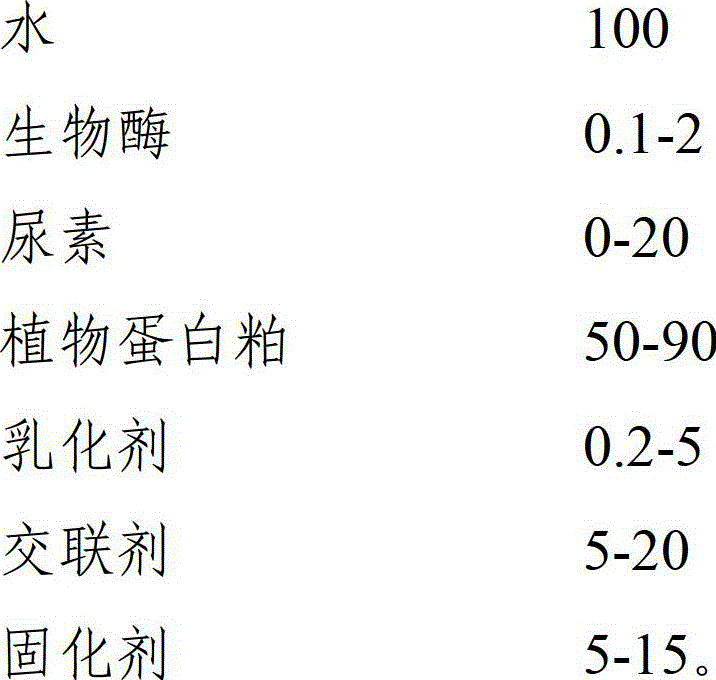

[0039] 1. Prepare materials according to the following weight ratio (Kg):

[0040]

[0041]

[0042] 2. Add all the above-mentioned raw materials into the reaction kettle, stir evenly, and obtain the vegetable protein meal solution;

[0043] 3. Adjust the pH value of the solution to 7.0 with NaOH, react at 50°C for 60 minutes, then raise the temperature to 90°C, and completely inactivate the biological enzyme;

[0044] 4. Add 1Kg of PEO-PPO-PEO emulsifier, and process it with a homogenizer to make it fully emulsified and dispersed, with a pressure of 60MPa, and set aside;

[0045] 5. Add 15Kg of water-based epoxy resin crosslinking agent and 5kg of hexamethylenediamine curing agent before use, and stir evenly. The performance indicators of the vegetable protein adhesives are detected, as shown in Table 1.

Embodiment 2

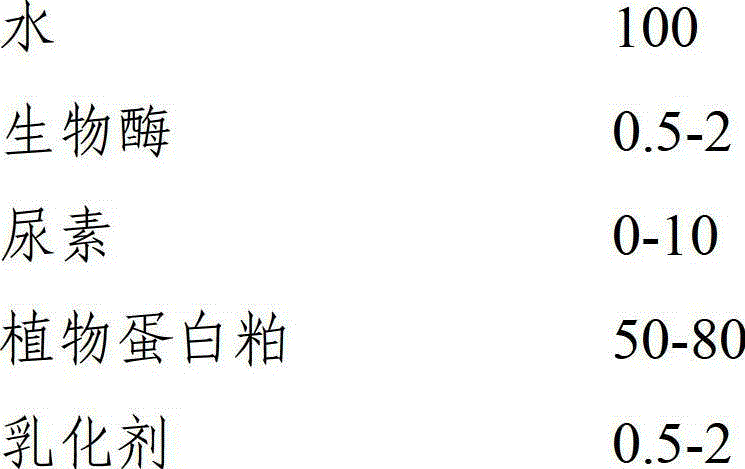

[0047] 1. Prepare materials according to the following weight ratio (Kg):

[0048]

[0049] 2. Add all the above-mentioned raw materials into the reaction kettle, stir evenly, and obtain the vegetable protein meal solution;

[0050] 3. KOH adjusted the pH value of the solution to 7.0, reacted at 50°C for 180 minutes, then raised the temperature to 90°C, and completely inactivated the biological enzyme;

[0051] 4. Add 0.5Kg sorbitan fatty acid ester emulsifier, 0.7Kg SDS and 0.8KgPEO-PPO-PEO, and process it with a homogenizer to make it fully emulsified and dispersed, and set aside;

[0052] 5. Before use, add 10Kg of water-based epoxy resin crosslinking agent and 4kg of diethylenetriamine, and stir evenly. The performance indicators of the vegetable protein adhesives are detected, as shown in Table 1.

Embodiment 3

[0054] 1. Prepare materials according to the following weight ratio (Kg):

[0055]

[0056] 2. Add all the above-mentioned raw materials into the reaction kettle, stir evenly, and obtain the vegetable protein meal solution;

[0057] 3. NaOH adjusted the pH of the solution to 5.5, reacted at 50°C for 120 minutes, then raised the temperature to 90°C, and completely inactivated the biological enzyme;

[0058] 4. Add 0.4Kg SDBS and 1.0Kg PEO-PPO-PEO, and process it with a homogenizer to make it fully emulsified and dispersed, and set aside;

[0059] 5. Before use, add 12Kg of water-based epoxy resin crosslinking agent and 8kg of m-phenylenediamine, and stir evenly. The performance indicators of the vegetable protein adhesives are detected, as shown in Table 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap