High-water-loss curing plugging agent for plugging fissures

A technology of plugging agent and high water loss, applied in the field of plugging agent, can solve the problems of not easy to dissolve blockage by acid, high price, etc., and achieve the effect of easy blockage removal, low cost and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Each component and parts by weight of forming the plugging agent:

[0032] 50 parts of main material, 9 parts of filter aid, 23 parts of curing agent, 10 parts of fiber material and 8 parts of bridging material;

[0033] Wherein, the main material is calcium oxide;

[0034] The filter aid is calcium carbonate (purchased from Lingshou Aoke Petroleum Auxiliary Co., Ltd.);

[0035] The curing agent is magnesium sulfite (purchased from Tianjin COSL Chemical Co., Ltd.);

[0036] The fibrous material is wood chips;

[0037] The bridging material consists of walnut shells (purchased from Lingshou Aoke Petroleum Auxiliary Co., Ltd.), mica (purchased from Lingshou Aoke Petroleum Auxiliary Co., Ltd.) and rubber particles (Beijing Zhongke Risheng Technology Co., Ltd., model : PF-SGL) is mixed according to the mass ratio of 3:2:2, and the walnut shell is composed of coarse walnut shell with a particle size greater than 3.35mm, medium walnut shell with a particle size of 1.68-3.3...

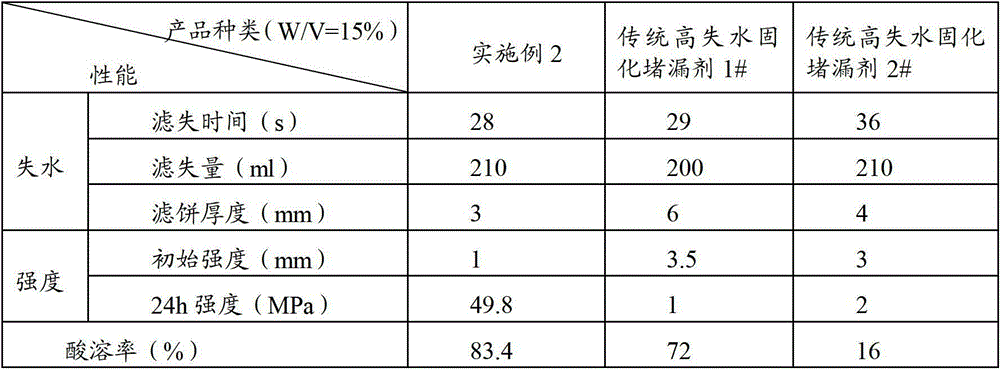

Embodiment 2

[0042] Components and parts by weight of the plugging agent: 60 parts of main material, 10 parts of filter aid, 15 parts of curing agent, 8 parts of fiber material and 7 parts of bridging material;

[0043] Wherein, the main material is magnesium oxide;

[0044] The filter aid is calcium carbonate (purchased from Lingshou Aoke Petroleum Auxiliary Co., Ltd.);

[0045] The curing agent is sodium sulfite (purchased from Tianjin Anqing Fine Chemical Co., Ltd.);

[0046] The fibrous material is paper scraps;

[0047] The bridging material is made by mixing walnut shells, mica and rubber particles in a mass ratio of 3:2:2. The walnut shells are composed of coarse walnut shells with a particle size greater than 3.35mm and medium walnut shells with a particle size of 1.68-3.35mm. It is mixed with fine walnut shells with a particle size of 0.38-1.68mm at a mass ratio of 1:1:1; mica is composed of medium mica with a particle size of 0.38-0.8mm and fine mica with a particle size of les...

Embodiment 3

[0053] Components and parts by weight of the plugging agent: 70 parts of main material, 10 parts of filter aid, 10 parts of curing agent, 5 parts of fiber material and 5 parts of bridging material;

[0054] Among them, the main material is alumina;

[0055] The filter aid is calcium carbonate (purchased from Lingshou Aoke Petroleum Auxiliary Co., Ltd.);

[0056] The curing agent is sodium hypophosphite (purchased from Tianjin Zhengan Chemical Trade Co., Ltd.);

[0057] The fibrous material is a mixture of wood chips and paper chips;

[0058] The bridging material is made by mixing walnut shells, mica and rubber particles in a mass ratio of 3:2:2. The walnut shells are composed of coarse walnut shells with a particle size greater than 3.35mm and medium walnut shells with a particle size of 1.68-3.35mm. It is mixed with fine walnut shells with a particle size of 0.38-1.68mm at a mass ratio of 1:1:1; mica is composed of medium mica with a particle size of 0.38-0.8mm and fine mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com