Underground high-pressure hydraulic fracturing hole sealing material for coal mine and hole sealing technology

A technology of hydraulic fracturing and sealing materials, which is applied in the direction of sealing/isolation, wellbore/well components, drilling composition, etc., which can solve the problems of large shrinkage, insufficient sealing depth, thin slurry, etc., and achieve reduction The effect of water loss, sealing depth and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

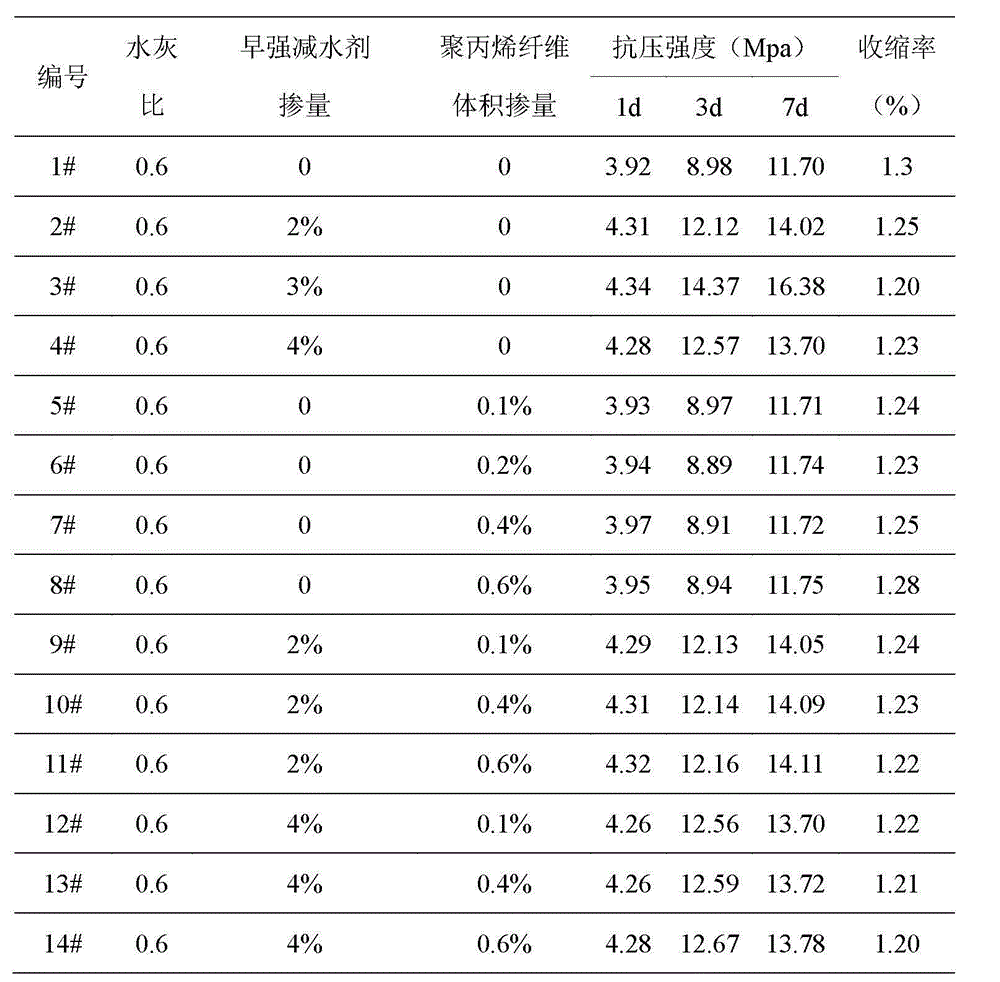

[0022] Example 1: The components of the sealing material are: 100 parts of cement, 60 parts of water, 2 to 4 parts of early strength superplasticizer, and 0.08 to 0.5 parts of polypropylene fiber (volume content of 0.1 to 0.6%).

[0023] Table 1 Experimental data of sealing material ratio

[0024]

Embodiment 2

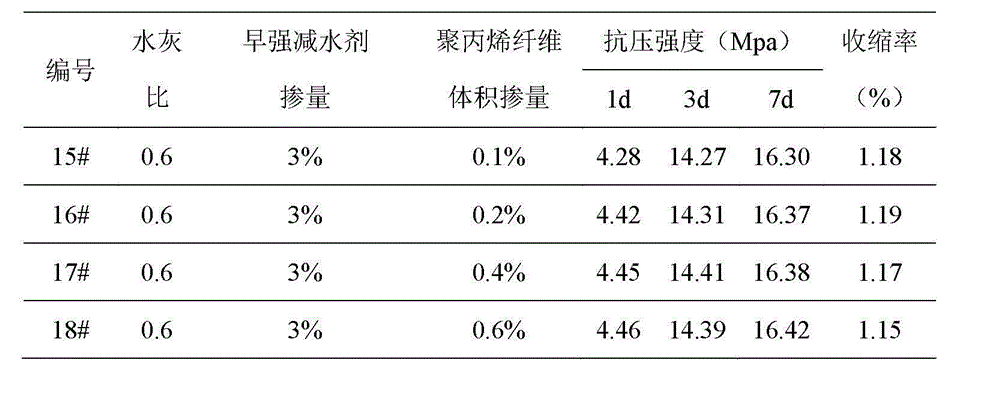

[0025] Example 2: The components of the sealing material are: 100 parts of cement, 60 parts of water, 3 parts of early-strength superplasticizer, and 0.08-0.5 parts of polypropylene fiber (volume dosage 0.1-0.6%).

[0026] It can be seen from the 18th group of data in Table 2 that when the dosage of early strength superplasticizer is 3% and the volume dosage of polypropylene fiber is 0.6%, the strength is the largest and the shrinkage is the smallest.

[0027] Table 2 Experimental data of the optimal ratio of sealing materials

[0028]

[0029] In the above plan, the polypropylene fiber is an inert material. It is compatible with the Ms early-strength superplasticizer and has good compatibility without affecting other properties of the slurry. The Ms early-strength superplasticizer is directly added to the mixing water, and the polypropylene fiber Dry mix with cement first, mix evenly, then add water to make it evenly distributed in the slurry, and will not block pipelines ...

Embodiment

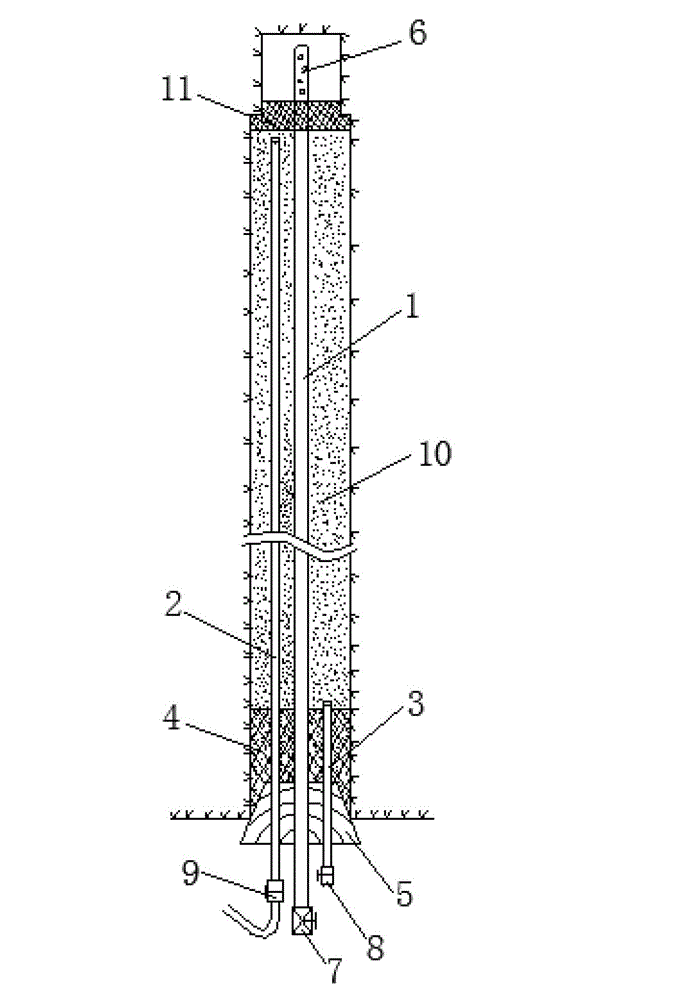

[0031] Embodiment: sealing process, as figure 1 shown, including the steps in the following order:

[0032] a Drill a hole with a diameter of 75mm on the coal rock mass, construct it to the top of the coal seam, and ream the hole to the bottom of the coal seam with a drill bit with a diameter of Φ94mm.

[0033] b. Send the fracturing pipe 1 to the roof of the coal seam at the bottom of the borehole. The front part of the fracturing pipe 1 is the screen 6, and the screen 6 is wrapped with gauze with a length of 50-100 cm to prevent the backflow of the sealing slurry from blocking the fracturing pipe; The lower end of the pipe 6 wraps and binds cotton yarn to form a cotton yarn plug 11, which is used to plug the hole section at the junction of the coal seam floor and the coal-rock mass, and plays the role of sealing the hole sealing slurry 10 and filtering water. The split pipe 1 is connected and put into the borehole until it reaches the bottom of the borehole. Send the grout...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com