Sinter feeding system and method for improving burden distribution of blast furnace

A technology for sinter and blast furnace, applied in blast furnace, blast furnace details, blast furnace parts and other directions, can solve the problems of high density of material layer, loss, green core, etc., to achieve flexible adjustment, control particle size segregation, and improve air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

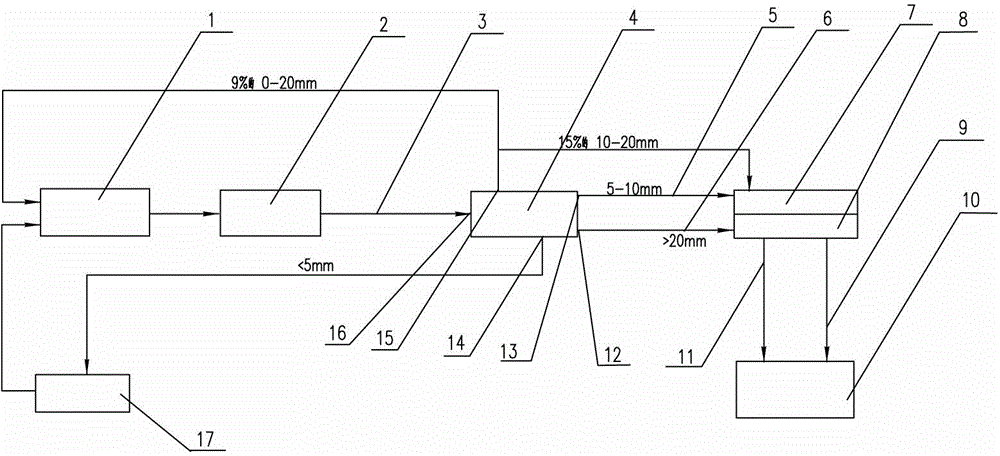

[0011] The present invention will be further described below in conjunction with accompanying drawing.

[0012] Such as figure 1 As shown, the sinter feeding system for improving blast furnace material distribution of the present invention includes a sinter feeding device 1, an annular cooler 2, a sinter conveying belt conveyor 3, a finished product trough, and a material distribution system between the finished product trough and the blast furnace roof. The finished ore conveying belt machine between the devices is characterized in that a screening machine 4 is provided between the sintered ore conveying belt 3 and the finished product ore tank, and the described screening machine 4 is a three-stage screening machine, and the three-stage screening machine is equipped with There are feed inlet 16, large-size finished ore discharge outlet 12 corresponding to the product on the primary sieve > 20mm, and 10-20mm finished ore medium-sized bottom layer discharge outlet 15 correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com