Multi-blade molten iron desulphurization stirring device

The technology of molten iron desulfurization and stirring device is applied in the field of desulfurization device in metallurgical casting industry, which can solve the problems of unsatisfactory desulfurization effect of stirring head and affecting the service life of the system, and achieve the effects of simple structure, energy saving and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

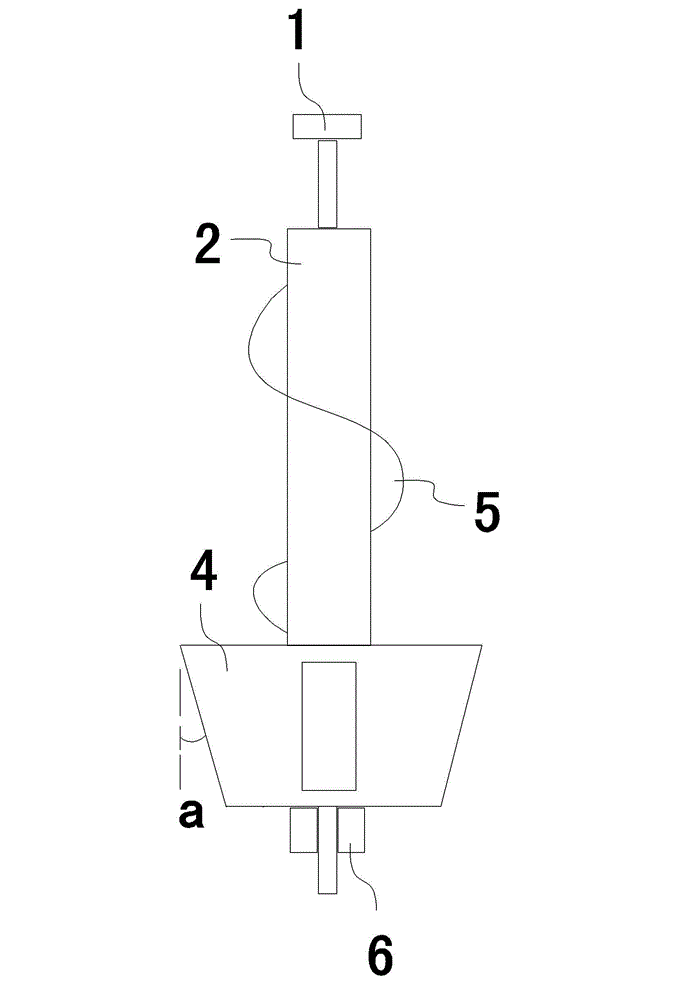

[0014] As shown in the figure, the multi-blade molten iron desulfurization stirring device includes a flange connection 1, a stirring shaft 2 fixedly connected to the flange connection 1, and a stirring blade 4 fixedly connected to the lower part of the stirring shaft 2; The top of the stirring blade 4 is fixedly equipped with a helical blade 5 .

[0015] In order to increase the stirring effect, the present invention is fixed with an auxiliary stirring blade 6 at the bottom of the stirring blade 4 .

[0016] The vertical deflection angle of the stirring blade 4 in the present invention is 10°≤a≤20°, and the vertical deflection angle a of the facade is preferably 13°

[0017] When the spiral blade 5 of the present invention is in operation, it also has the function of making the desulfurizer powder deeply penetrate into the melt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com