Device for machining F-shaped steel used in track skeleton for magnetic levitation train

A technology for a maglev train and a processing device, which is applied to tracks, track laying, track maintenance, etc., can solve the problems of inability to directly measure and process rail bolt hole groups, large processing errors, and waste of resources, avoiding direct measurement and positioning. , high cost, the effect of avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

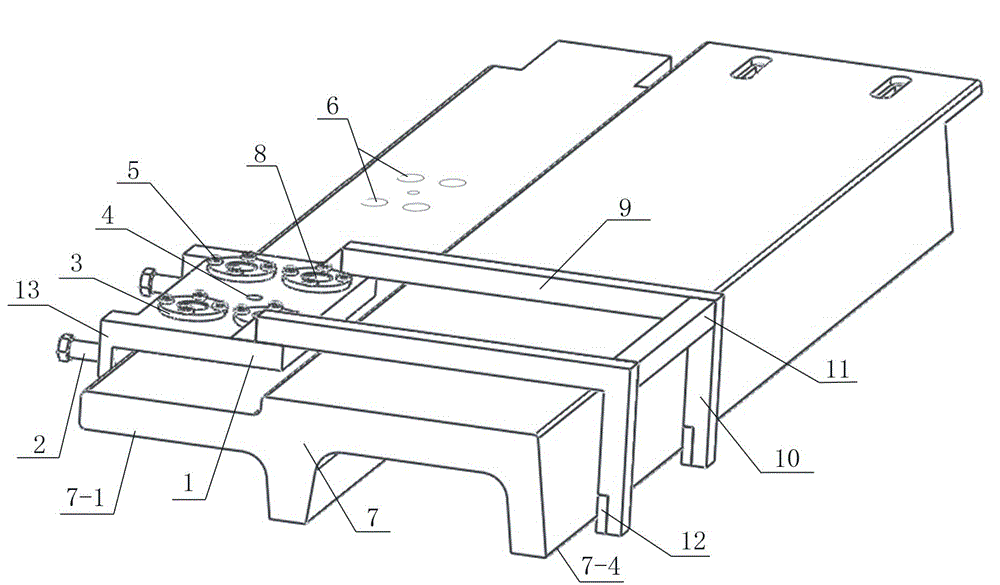

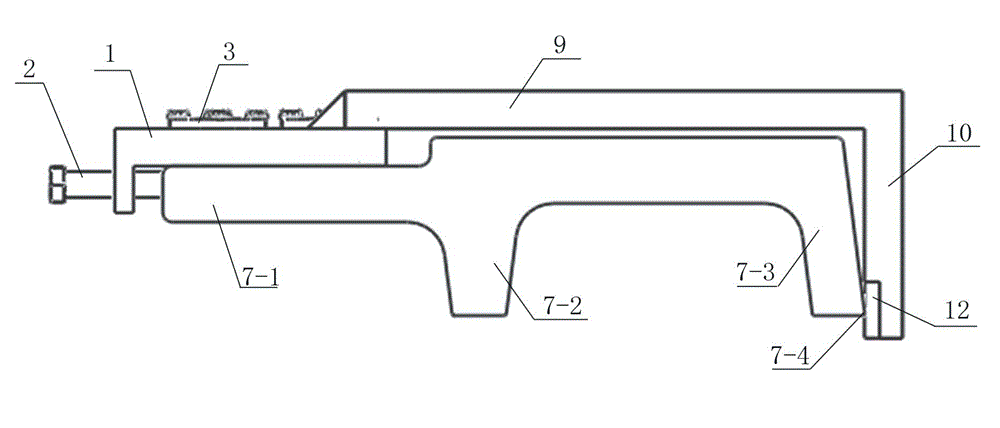

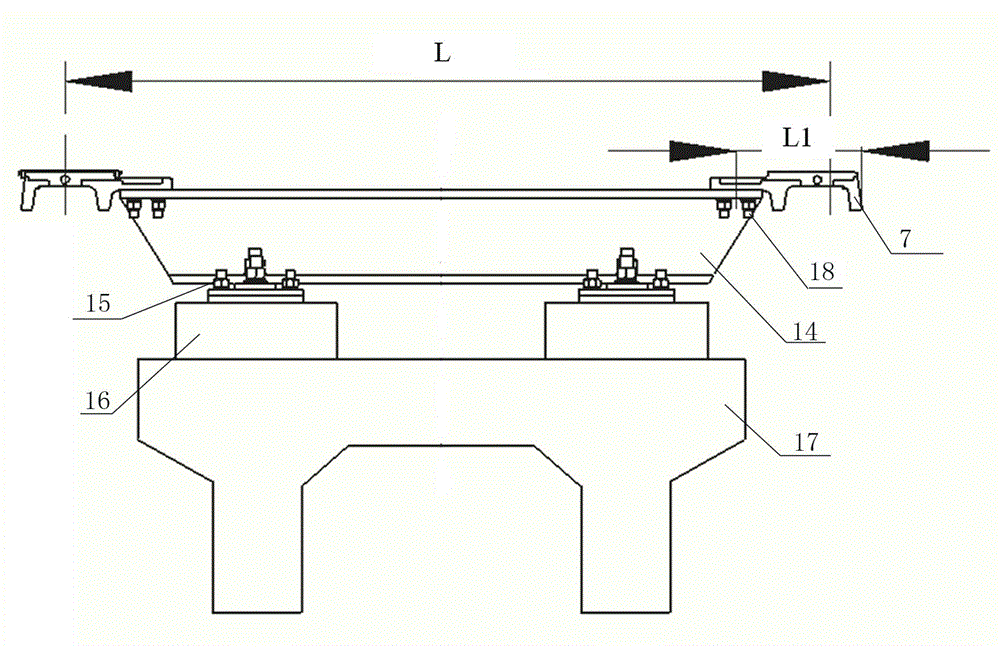

[0017] like figure 1 and figure 2 As shown, a schematic diagram and a front view of the three-dimensional structure of the processing device of the present invention in cooperation with F-shaped steel are provided, and the shown F-shaped steel 7 is composed of a wing plate 7-1, an inner pole web 7-2 and an outer pole web 7- 3 components, the lower right of the outer pole web 7-3 is the outer corner 7-4; during the use of the F-shaped steel 7, bolt hole groups 6 need to be processed on its wing plate 7-1. The shown processing device comprises a central module 1, a horizontal support 9, a vertical support 10, a side plate 13, a tightening rod 2, a spacer sleeve 3, a connecting rod 11, and a side plate 13; The upper surface of -1 matches, and the four limit sleeves 3 are arranged on the central module 1 according to the size requirements of the bolt hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com