Steel truss girder all-welded joist slice and construction method thereof

A technology for steel truss girders and truss pieces, applied in the field of steel truss girder fully welded truss pieces and its construction, which can solve the problems of large number of welds on the construction site, high work intensity, and slow construction progress, so as to achieve fast construction progress and improve work efficiency. Efficiency, the effect of ensuring the quality of steel beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

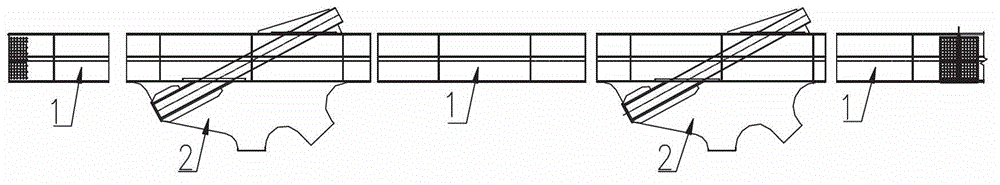

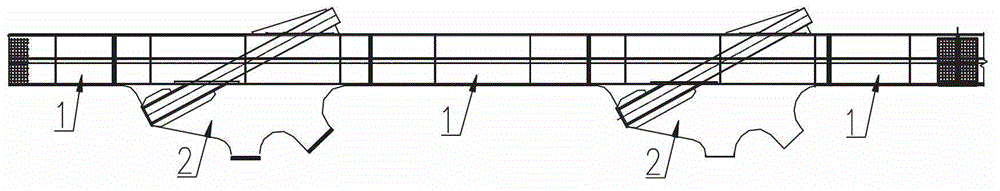

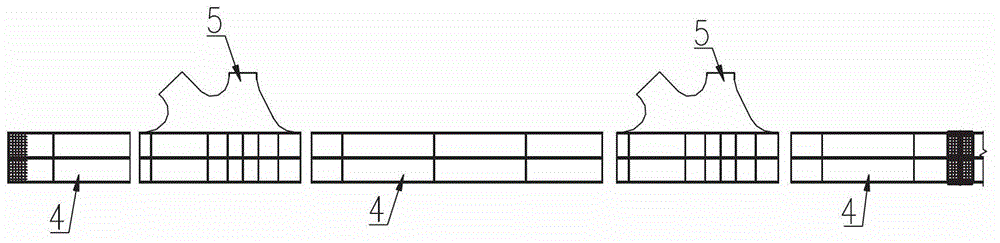

[0022] The present invention is a fully welded truss piece of a steel truss girder, two upper chord integral nodes 2 are welded at both ends and in the middle to form an integral upper chord 1 to form an integral upper chord 3, two lower chord integral nodes 5 are welded at both ends and in the middle to form a lower chord 4 The integral lower chord 6, the upper and lower ends of the oblique bar 7 and the vertical bar 8 are welded to the integral nodes of the integral upper chord member 3 and the integral lower chord member 6 respectively.

[0023] The sections of the upper chord 1 and the lower chord 4 are box-shaped. The section of the oblique bar 7 and the vertical bar 8 is box-shaped or I-shaped.

[0024] Construction method of the present invention, concrete steps are as follows:

[0025] 1) The outer ends of the two upper chord integral nodes 2 are butt penetration welded with the two upper chord rods 1, the inner ends are butt penetration welded with the two upper chor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com