Integral drawing type tunnel boring machine (TBM) inverted arch block core mold

A pull-out and mandrel technology, used in shaft equipment, shaft lining, mining equipment, etc., can solve the problems of template deformation and long occupation time, and achieve the effect of reducing time, increasing work efficiency, reducing air bubbles and seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

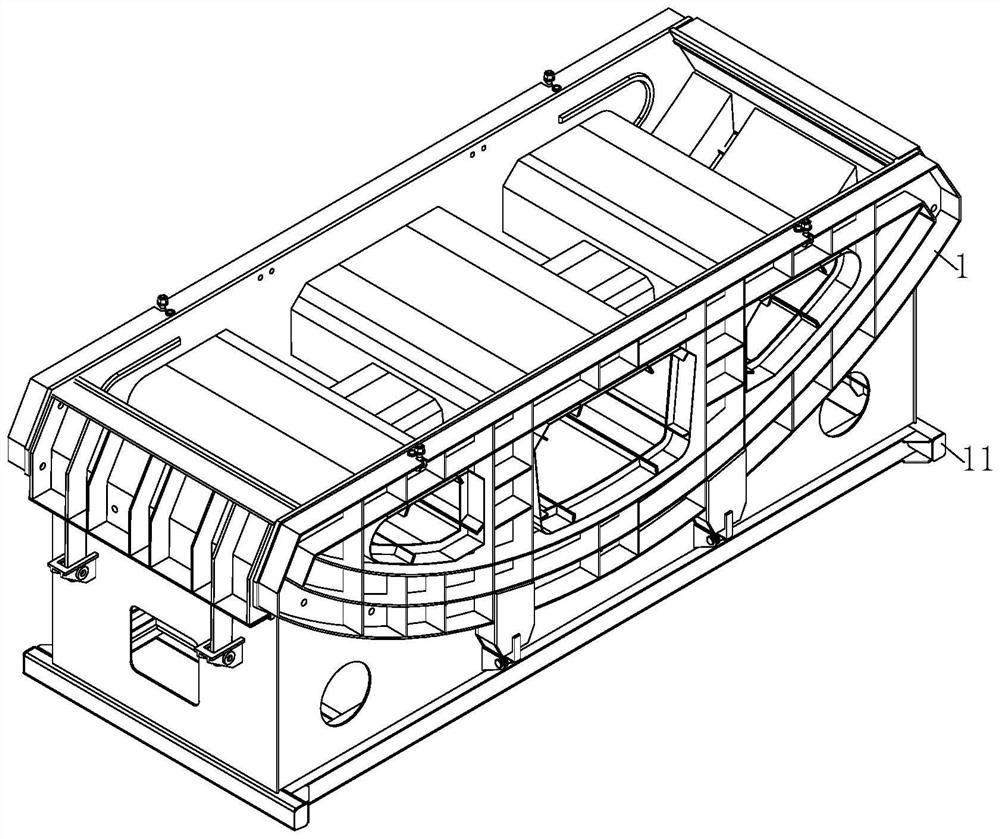

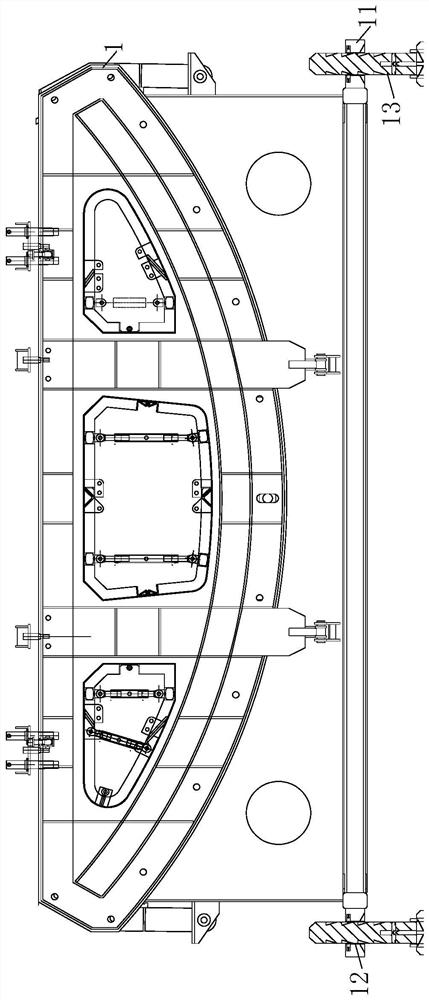

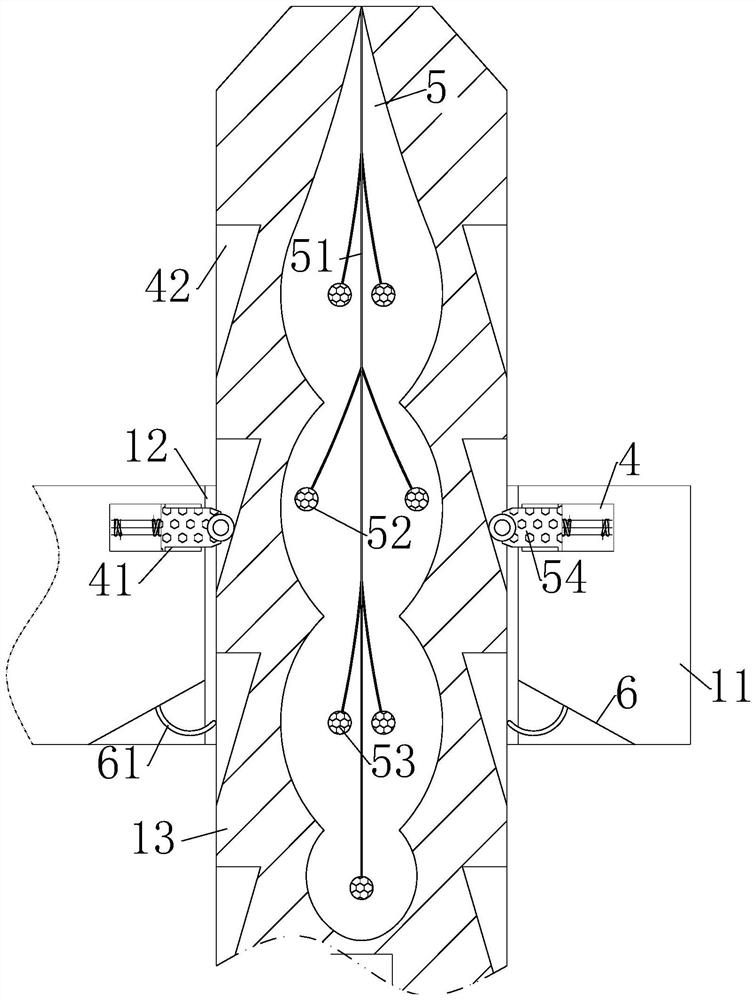

[0031] like Figure 1 to Figure 2 As shown, a kind of integral pulling type TBM inverted arch block core mold described in the embodiment of the present invention comprises inverted arch block core mold 1; the bottom surface of the inverted arch block core mold 1 is fixed with a bottom film 11; The top surface of the membrane 11 is located at the four corners and runs through a No. 1 chute 12; the interior of the multiple groups of the No. 1 chute 12 is slidably connected with a positioning rod 13; during operation, in the tunnel construction stage, with the continuous extension of the excavation depth, In order to protect the safety of the tunnel, it is often necessary to gradually lay the inverted arch blocks to disperse the stress on the supporting structure above the tunnel to both sides, and at the same time, it can effectively resist the reaction force from the lower stratum of the tunnel. The existing inverted arches are often made of reinforced concrete. Structure, the...

Embodiment 2

[0041] like Figure 7 As shown, Comparative Example 1, in which another embodiment of the present invention is: a pair of rollers 101 are rotatably connected to the top side wall of the pressing plate 24; the rollers 101 are in contact with the end of the limit block 23; When the pressing plate 24 is pushed by the linkage rod 25, the roller 101 installed on the top of the pressing plate 24 uses its own rotation to contact the end of the limit block 23, and the auxiliary limit block 23 is pushed out. , which can assist the stop block 23 to be pushed out smoothly, reduce the occurrence of jamming, and improve the stability of the equipment during operation.

[0042] During the work, in the tunnel construction stage, as the excavation depth continues to increase, in order to protect the safety of the tunnel, it is often necessary to gradually lay the inverted arch blocks to disperse the force of the supporting structure above the tunnel to both sides, and at the same time, it can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com