Wedge-shaped self-locking pounder unhooking device

A technology of automatic decoupling and supporting claws, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of large oil cylinder design, high cost, slow decoupling of rammers, etc., and achieves improved operational safety, simple structure, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

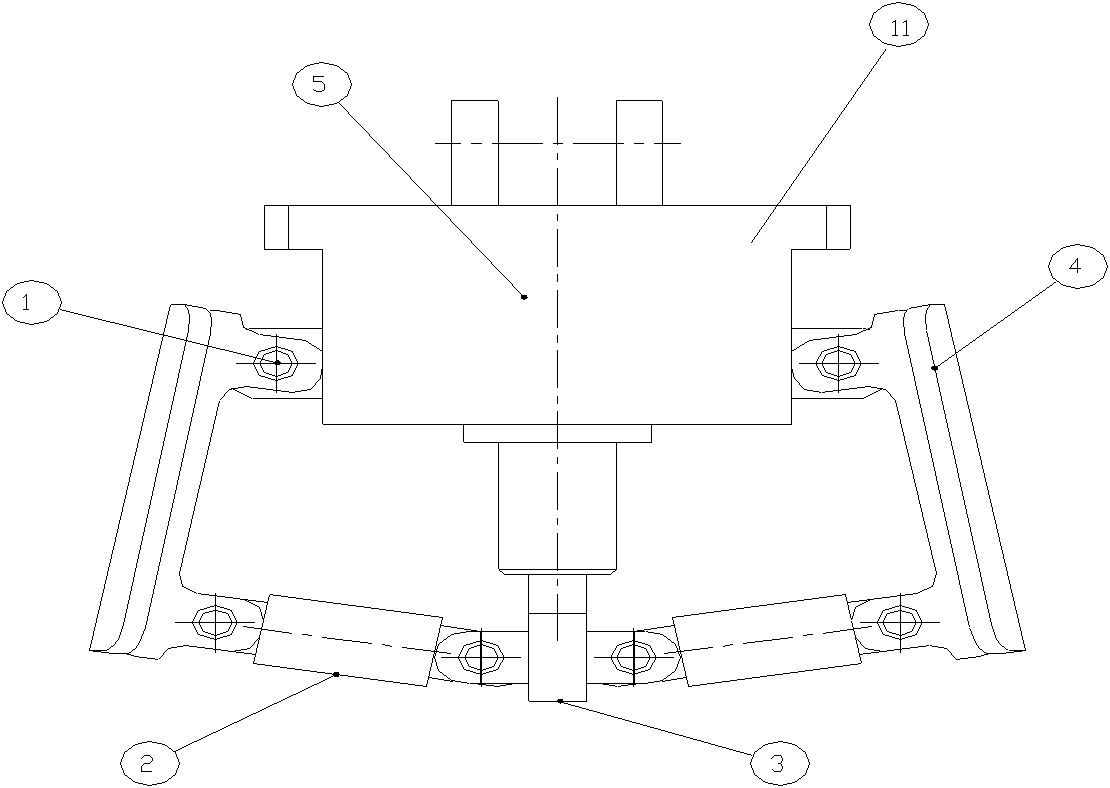

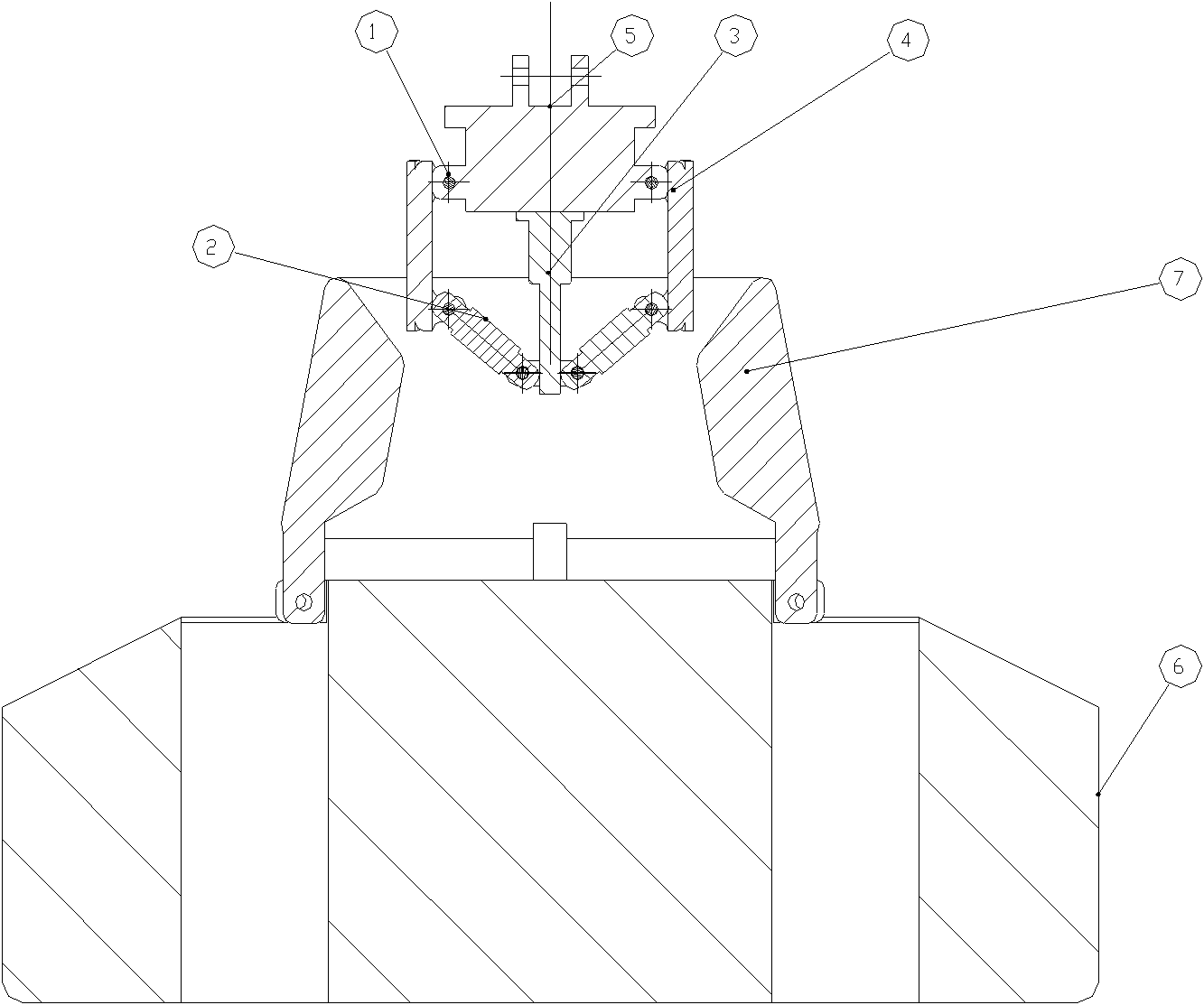

[0019] Such as image 3 , 4 Shown, according to the automatic decoupling device of the present invention is made of two parts that cooperate with each other, promptly comprises the automatic decoupling parts of automatic decoupling device according to the present invention (it is attached figure 1 Indicated generally by reference number 11) and appended image 3 , 4 Guide part 7 shown in .

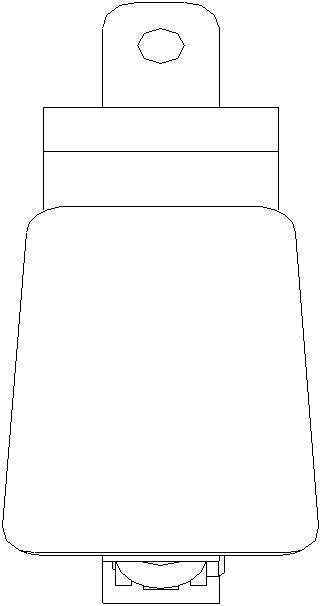

[0020] Such as figure 1 As shown, the automatic decoupling component 11 includes a hoisting bracket 5 as a main body component. The hoisting bracket is preferably cylindrical, but may also be in the shape of a parallelepiped, a truncated cone, a prism, or the like. As long as its center of gravity is on its central longitudinal axis. Lifting lugs are arranged on the top surface of the lifting bracket 5, through which the suspension hook of the dynamic compactor can lift the tamper. The side surfaces of the hoisting bracket 5 and the upper part of the supporting claw 4 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com