Concrete shear wall with continuous annular reinforcement structure

A technology of concrete shear wall and annular steel bar, applied in the direction of structural elements, walls, building components, etc., can solve the problems of poor ductility of shear walls, and achieve the goal of enhancing ductility, avoiding premature collapse, and improving ultimate deformation capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

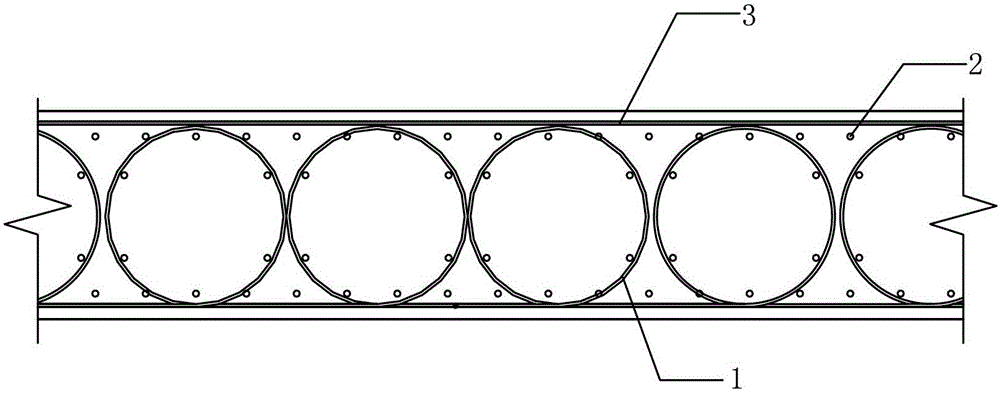

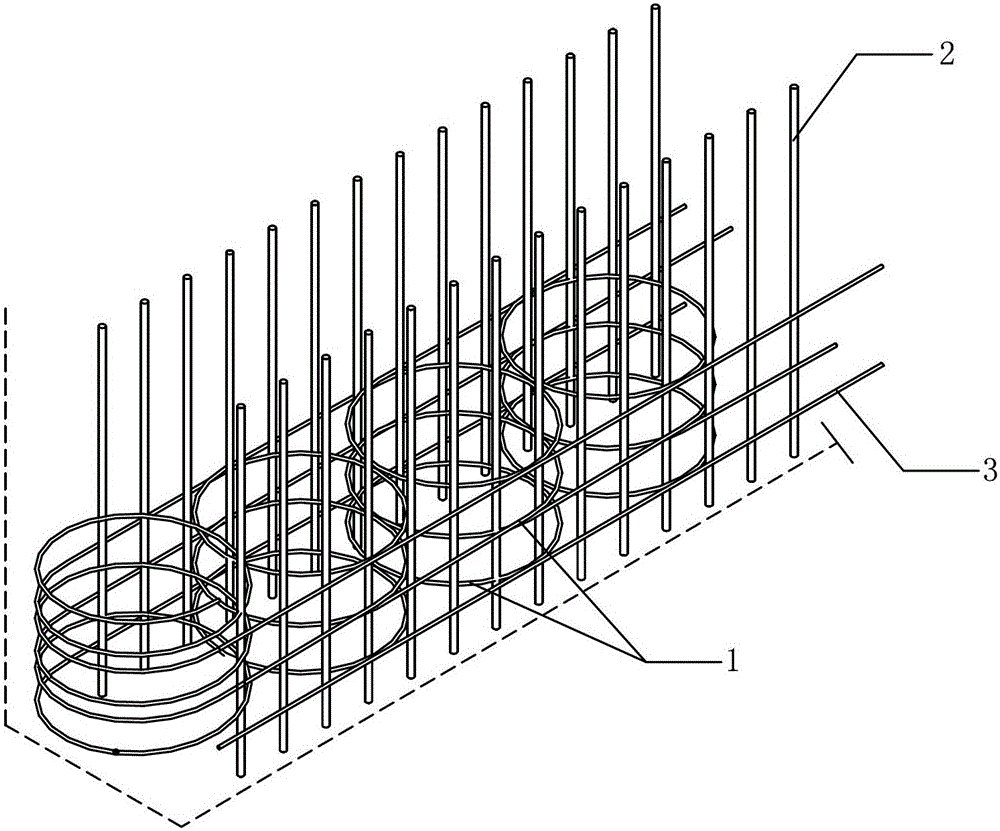

[0026] figure 1 with figure 2 It constitutes the specific embodiment 1 of the present invention.

[0027] Reference figure 1 with figure 2 This embodiment includes a wall and a steel frame built into the wall. The steel frame is composed of a horizontal ring-shaped steel bar structure 1 and a longitudinal steel bar structure 2. The horizontal ring-shaped steel bar structure 1 is composed of multiple layers of continuously distributed steel ring , The steel bars in the same layer are connected by 1-2 transverse steel bars 3 to form a whole, that is, a continuously distributed steel ring structure; the longitudinal steel bar structure 2 is composed of multiple longitudinal steel bars, and the longitudinal steel bars are arranged through the steel ring structure It is connected with the reinforcing steel ring and the transverse reinforcing steel 3, and at least part of the longitudinal reinforcing steel is located in the reinforcing steel ring.

[0028] In this embodiment:

[0029] I...

specific Embodiment 2

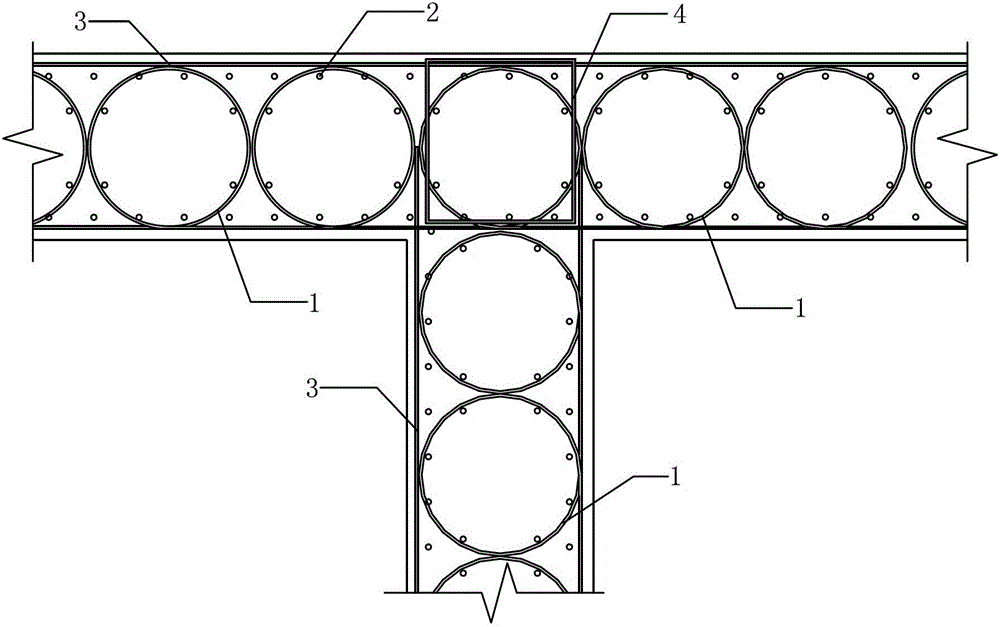

[0032] image 3 with Figure 4 It constitutes the specific embodiment 2 of the present invention.

[0033] Reference image 3 with Figure 4 The feature of this embodiment 2 is: the steel frame is a "T"-shaped wall frame with a wing wall, and the transverse ring-shaped steel bar structure 1 in the wing wall is composed of a steel bar wound into a plurality of continuously distributed steel rings , The horizontal ring-shaped steel bar structure 1 in the straight wall is composed of a steel bar that is wound into a plurality of continuously distributed steel rings and extends longitudinally and spirally at the junction with the wing wall to the height of another layer of the horizontal ring-shaped steel bar structure 1; The junction with the wing wall is provided with rectangular hoop and tie bars 4 adapted to the shape of the wall frame to adapt to the shape of the wall frame. The rest is the same as in Example 1.

specific Embodiment 3

[0034] Figure 5 It constitutes the specific embodiment 3 of the present invention.

[0035] Reference Figure 5 The feature of this embodiment 3 is that the steel frame is an "L"-shaped wall frame, and the horizontal ring-shaped steel structure 1 of each layer is composed of a plurality of continuously distributed steel rings that are wound along the "L" shape. The junction of the steel frame is composed of steel bars that are turned to extend; the junction of the "L"-shaped steel frame is provided with rectangular hoop and bracing 4 adapted to the shape of the steel frame to adapt to the shape of the wall frame. The rest is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com