Martensitic stainless steel sheet

A stainless steel plate and system technology, applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problem of high susceptibility to stress corrosion cracking of stainless steel, and achieve the goal of improving ultimate deformation capacity, excellent corrosion resistance, excellent strength and processability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

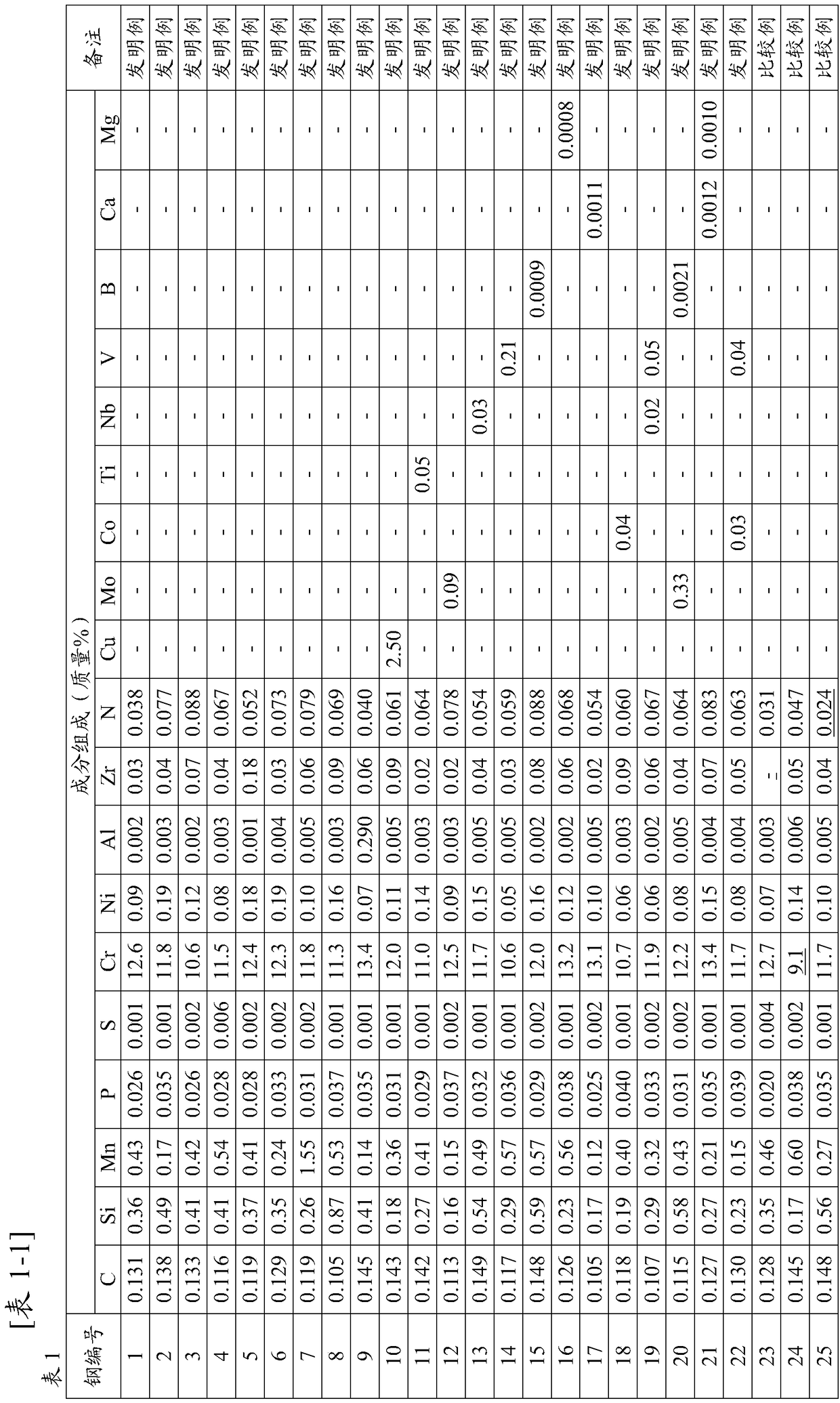

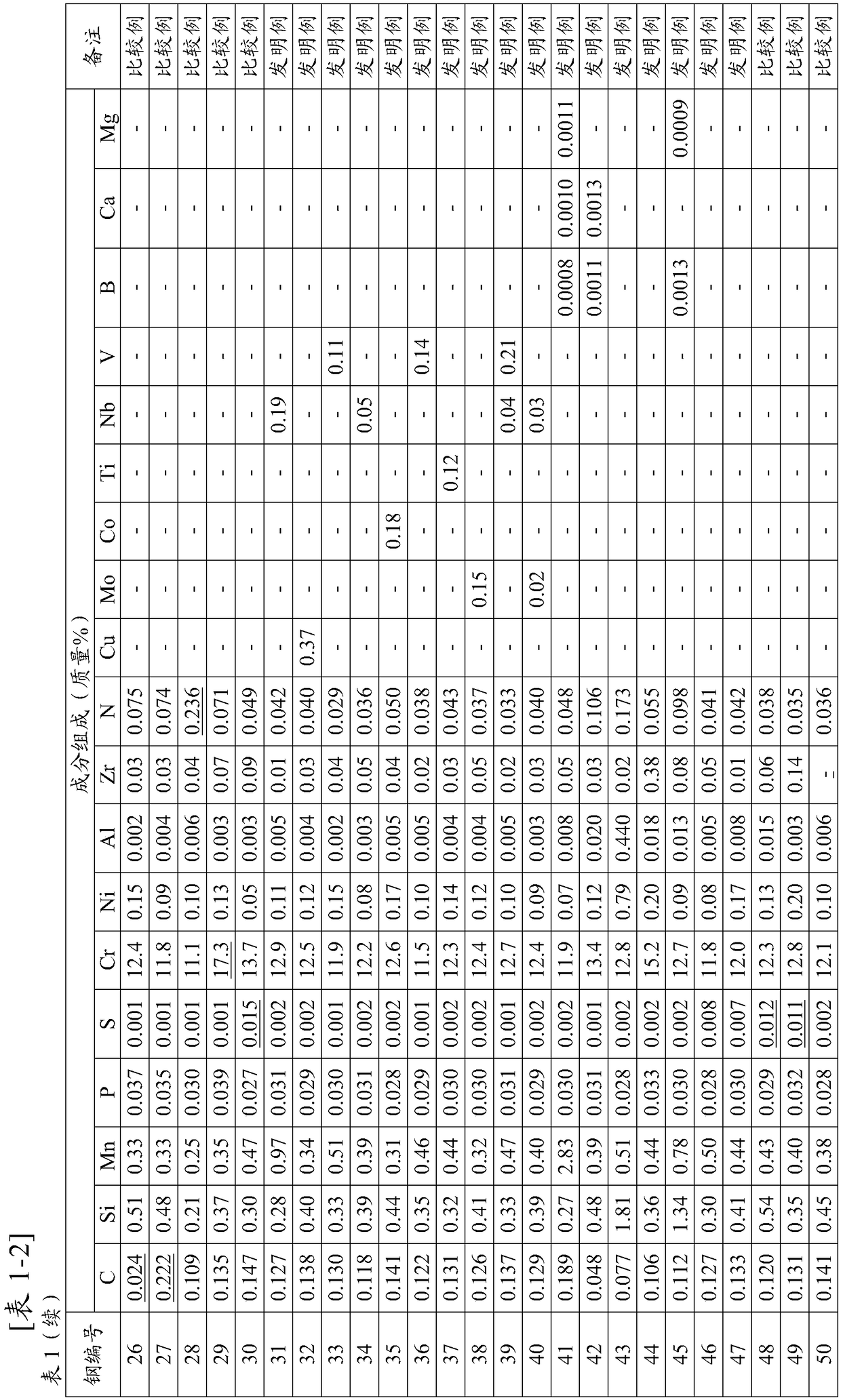

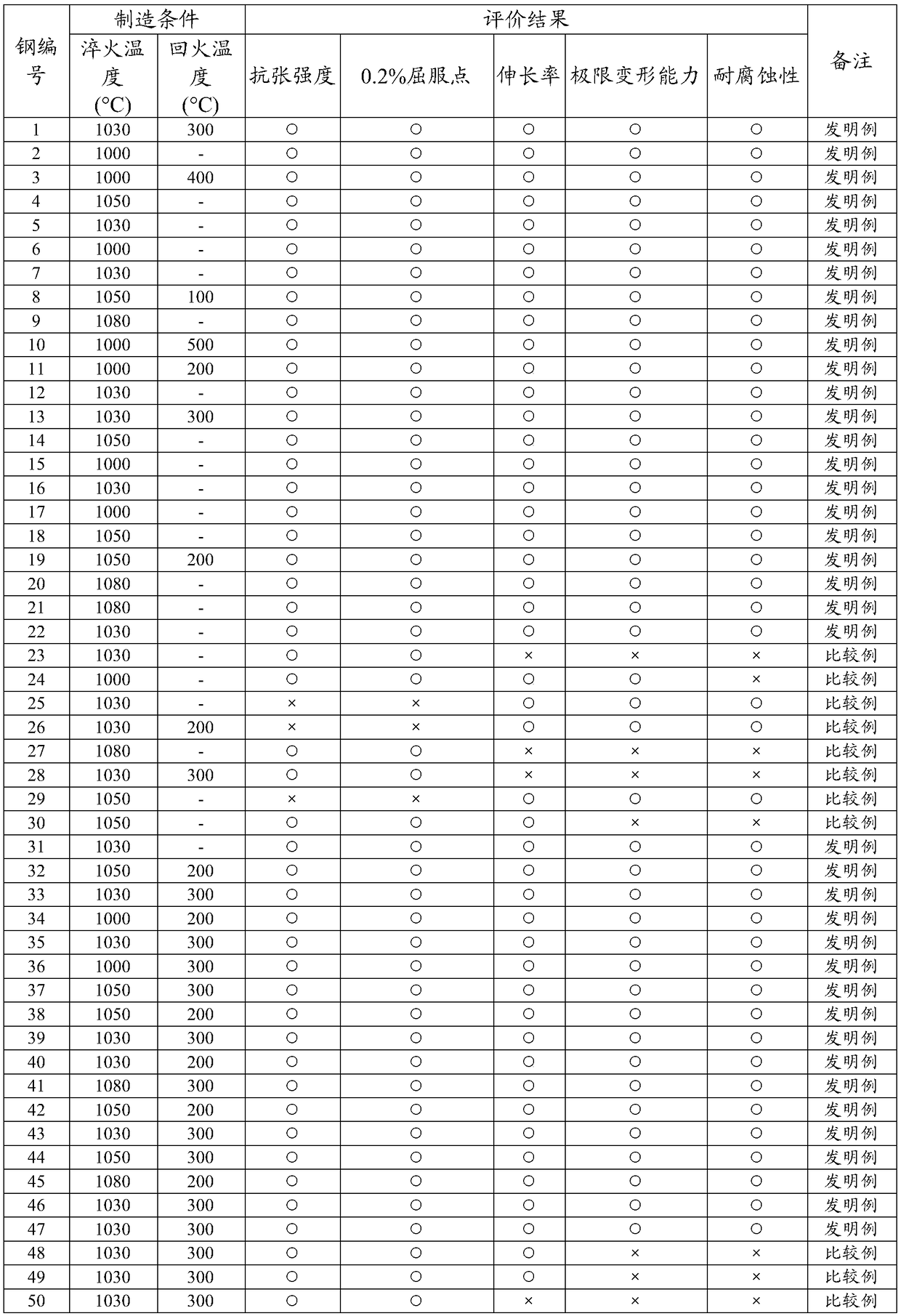

[0119] A 30 kg steel billet having the composition shown in Table 1 was melted and cast in a vacuum melting furnace. After being heated to 1200°C, hot rolling was performed to produce a thin slab of 25 mm in thickness and 150 mm in width. The thin slab was kept in a 700°C furnace for 10 hours and softened. Next, the thin slab was heated to 1100°C and then hot rolled to produce a hot rolled sheet having a thickness of 4 mm. Next, the hot-rolled sheet was kept in a furnace at 700° C. for 10 hours and annealed to produce a hot-rolled annealed sheet. Next, the hot-rolled annealed sheet was made into a cold-rolled sheet having a thickness of 0.2 mm by cold rolling, and was quenched and heat-treated at the temperature shown in Table 2 and then cooled. In addition, the cooling rate at this time is all set to 1 degreeC / sec or more. Furthermore, some cold-rolled sheets were subjected to tempering heat treatment at the temperature shown in Table 2 after cooling after the quenching hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com