Large-strain flexible cement concrete and preparation method thereof, and large-strain flexible cement concrete pavement layer

A cement concrete and large strain technology, applied in the field of concrete, can solve problems such as limited ultimate deformation capacity, large expansion and contraction deformation of steel box girders, corrosion of steel plates, etc., and achieve the effects of improving ultimate deformation capacity, ensuring flexural strength, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

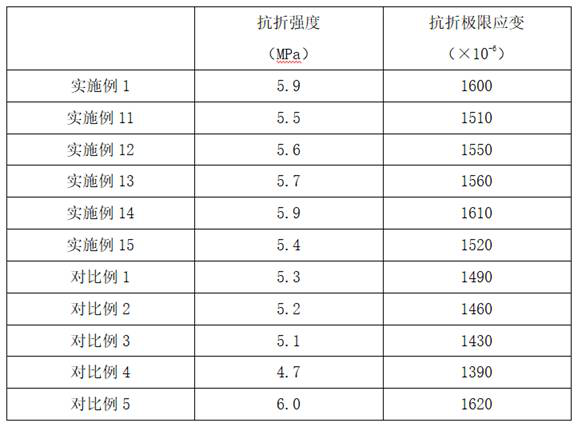

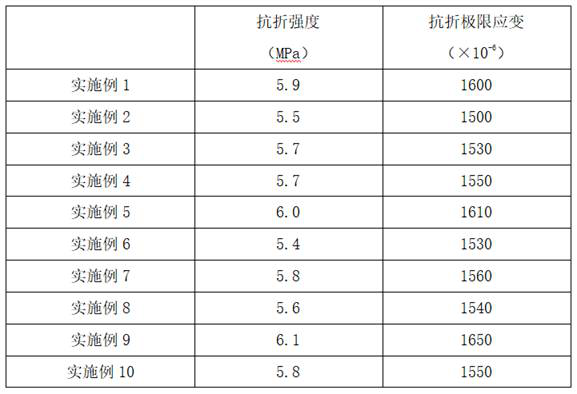

Examples

Embodiment 1

[0044] A preparation method of large strain flexible cement concrete, comprising the following preparation steps:

[0045] S1. Weigh each raw material according to the number of parts by mass, and the raw material components and consumption are shown in Table 1;

[0046] S2. Stir each raw material evenly to prepare large-strain flexible cement concrete for use.

[0047] The large-strain flexible cement concrete pavement layer is made from the above-mentioned large-strain flexible cement concrete pavement, and the pavement thickness is 30 mm.

Embodiment 2-5

[0049] Examples 2-5 The preparation method of large-strain flexible cement concrete is the same as that of Example 1, the only difference is that the amount of raw materials is different, as shown in Table 1.

[0050] Wherein, the pavement thickness of the large strain flexible cement concrete pavement layer in embodiment 2 is 40mm; The pavement thickness of the large strain flexible cement concrete pavement layer in embodiment 3 is 25mm; The large strain flexible cement pavement layer in embodiment 4-5 The pavement thickness of the concrete pavement layer is the same as that of Example 1, which is 30mm.

[0051] Raw material components and consumption in table 1 embodiment 1-5

[0052]

Embodiment 6

[0054] The preparation method of the large-strain flexible cement concrete in this example is the same as that in Example 1, the only difference is that no steel fiber is added to the raw materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com