Concrete insulating brick

A technology for thermal insulation bricks and concrete, applied in building components, buildings, building structures, etc., can solve the problems of poor thermal insulation effect, heavy weight, increase the weight of bricks, etc., to enhance thermal insulation effect, long service life, reduce product The effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0014]

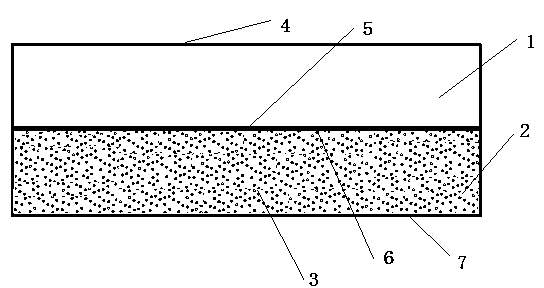

[0015] Such as figure 1 As shown, the present invention provides a concrete insulation brick, comprising a hard solid layer 1 and a cavity layer 2, the hard solid layer 1 has opposite first surface 4 and second surface 5, and the cavity layer 2 has a joint surface 6, A bottom surface 7 and several cavities 3 , the joint surface 6 and the bottom surface 7 are oppositely arranged on the cavity layer 2 , and the joint surface 6 and the second surface 5 are combined with each other, and the cavities are arranged in the cavity layer 2 .

[0016] In actual production, the hard layer 1 is formed by mixing cement, gravel and stone powder with water to make a crushed stone slurry, then using a mold to shape the crushed stone slurry, and gradually hardening after the water in the crushed stone slurry evaporates naturally. Since the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com