Threaded lip structural oil seal

A thread and lip technology, which is applied in the field of thread lip structure oil seals, can solve the problems of difficult control of product inner diameter, stability of sealing performance, and complicated production process control, so as to save production process and ensure stability , the effect of reducing risks and hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

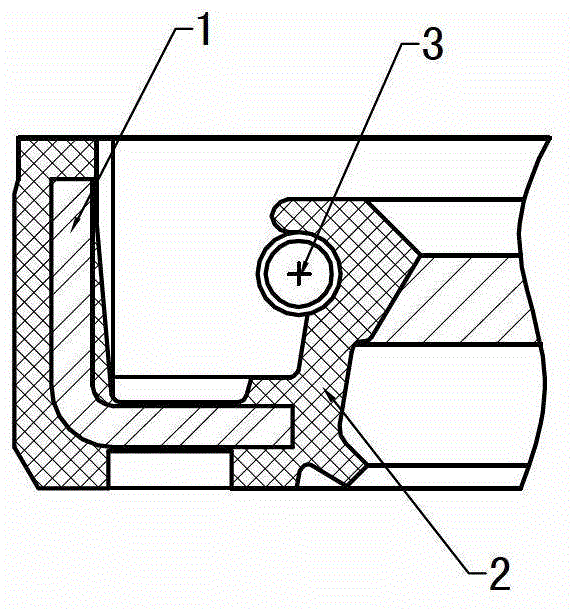

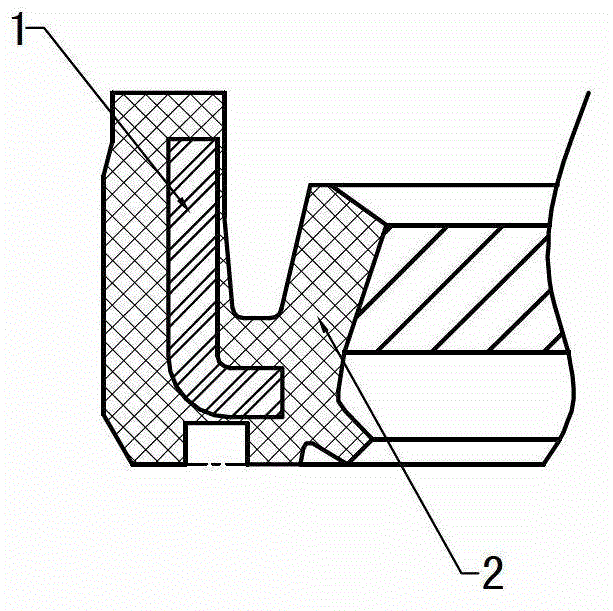

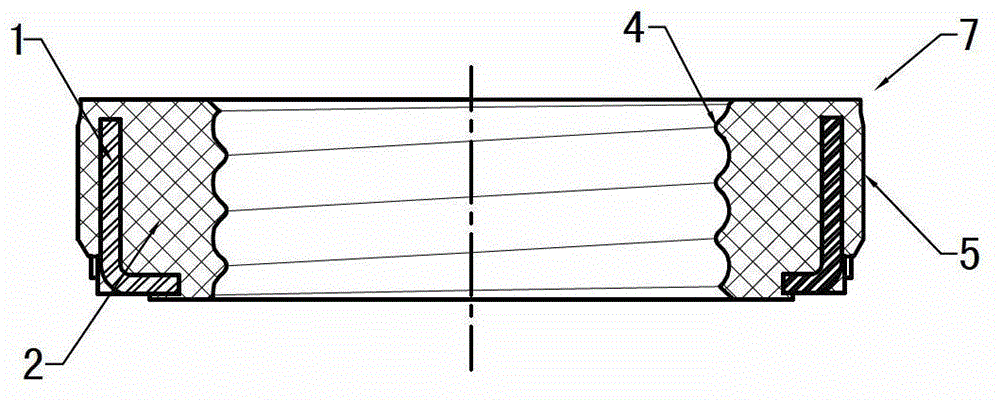

[0011] refer to image 3 , an oil seal with a threaded lip structure, consisting of an annular rubber body 2 and a skeleton 1 placed in the rubber body through vulcanization, the outer wall 5 of the oil seal of the annular rubber body 2 is in sealing fit with the inner wall of the cavity 6, so The inner wall of the ring-shaped rubber body 2 is a threaded lip 4 with more than 2 teeth, and the threaded lip and the working shaft 9 are tightly fitted, and the rotation structure of the threaded lip 4 is opposite to the rotating direction of the working shaft 9 .

[0012] The present invention is composed of two main body skeletons 1 and an annular rubber body 2, which is the same structure as the traditional oil seal, but without a spring structure, vulcanized and bonded by a vulcanization mold, and the sealing lip is designed as a threaded structure after molding. The crest radius, pitch and depth of the thread structure are the key structures of this oil seal. The mating surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com