Quick-opening gate type external pressure air-tightness test tank

A door-opening, test tank technology, applied in the direction of using liquid/vacuum for liquid tightness measurement, etc., can solve the problem that the external pressure airtight test tank cannot adopt a quick-opening structure, etc., to improve safety, economy, and operation. The effect of convenience and reduced operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

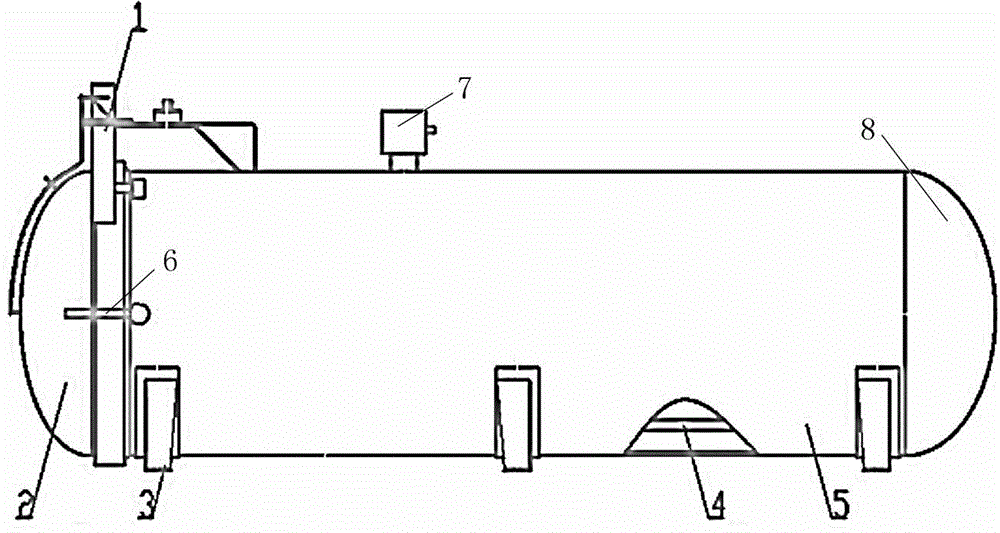

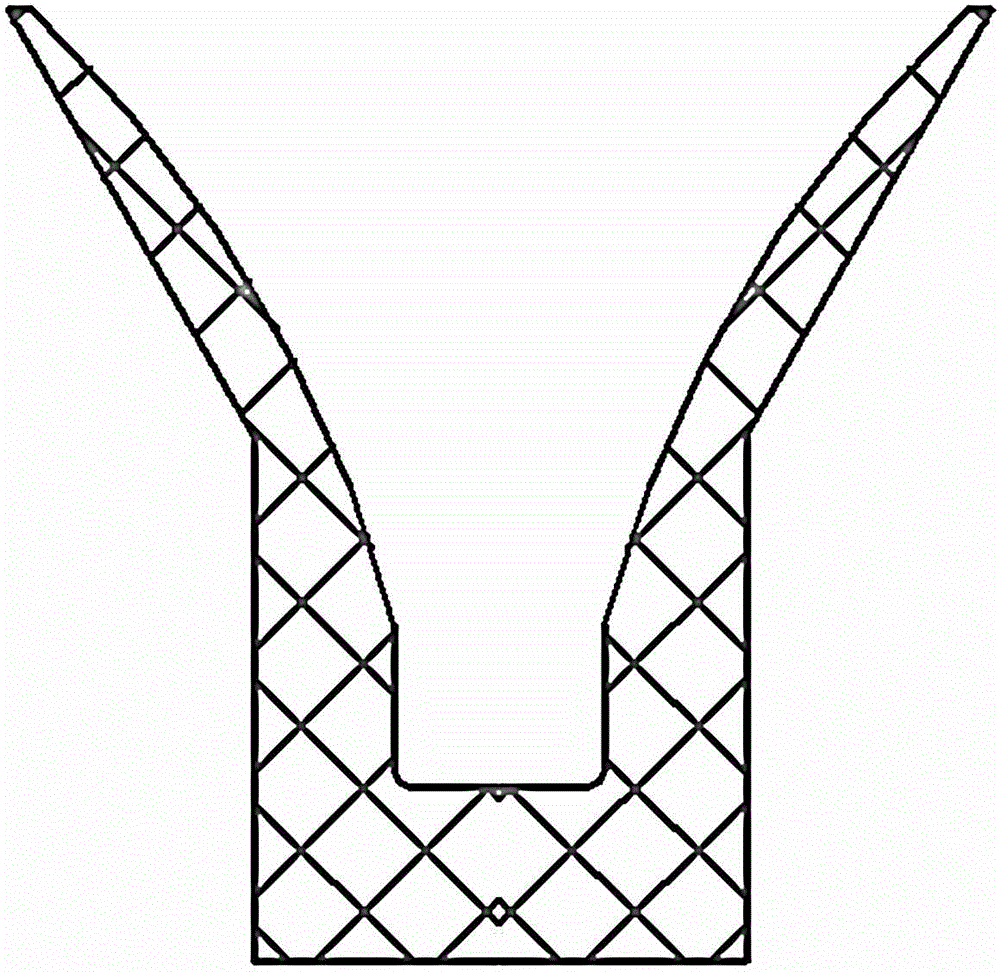

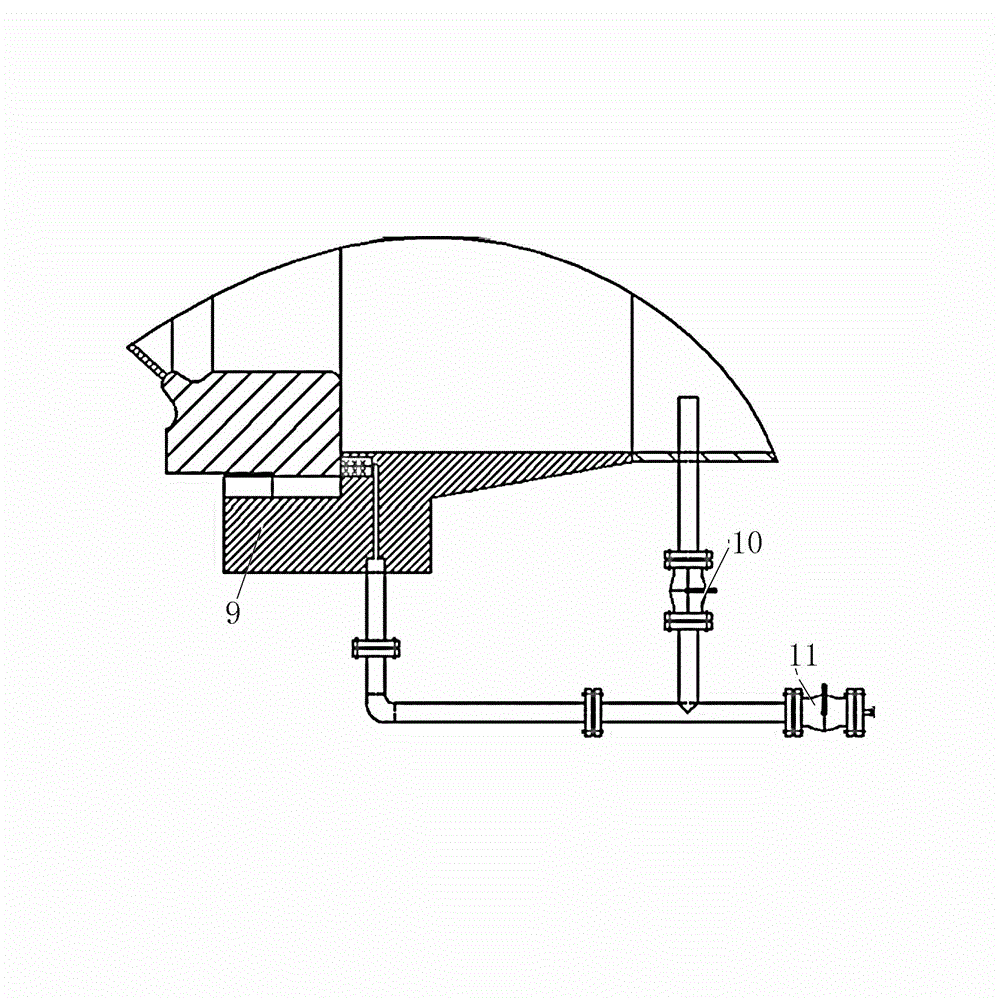

[0030] Such as Figure 1-6 As shown, the horizontal quick-opening door structure of the kettle is adopted. The kettle body includes an oval head 8, a cylinder body 5, and a kettle body flange. The lower part of the kettle body is provided with three supports 3, and the three supports 3 are installed horizontally with three saddles. One end of the kettle body is provided with a movable kettle cover 2, and the movable kettle cover 2 is connected to the kettle body through the direct bite mode of the kettle cover flange and the kettle body flange, and the kettle cover flange and the kettle body flange are sealed with a sealing ring 9 under pressure The sealing structure, the material of the sealing ring 9 adopts nitrile rubber. The movable kettle cover 2 includes a spherical head and a kettle cover flange. The opening direction of the movable kettle cover 2 is circumferential rotation and side rotation. The movable kettle cover 2 is equipped with a kettle cover opening system pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com