Corrugated pipe?expansion joint internal pressure bursting test device

A technology of blasting test and blasting test bench, which is applied in the field of bellows expansion joints, can solve problems such as unreliable axial constraints, and achieve the effects of strong versatility of the device, avoiding protrusion deformation, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

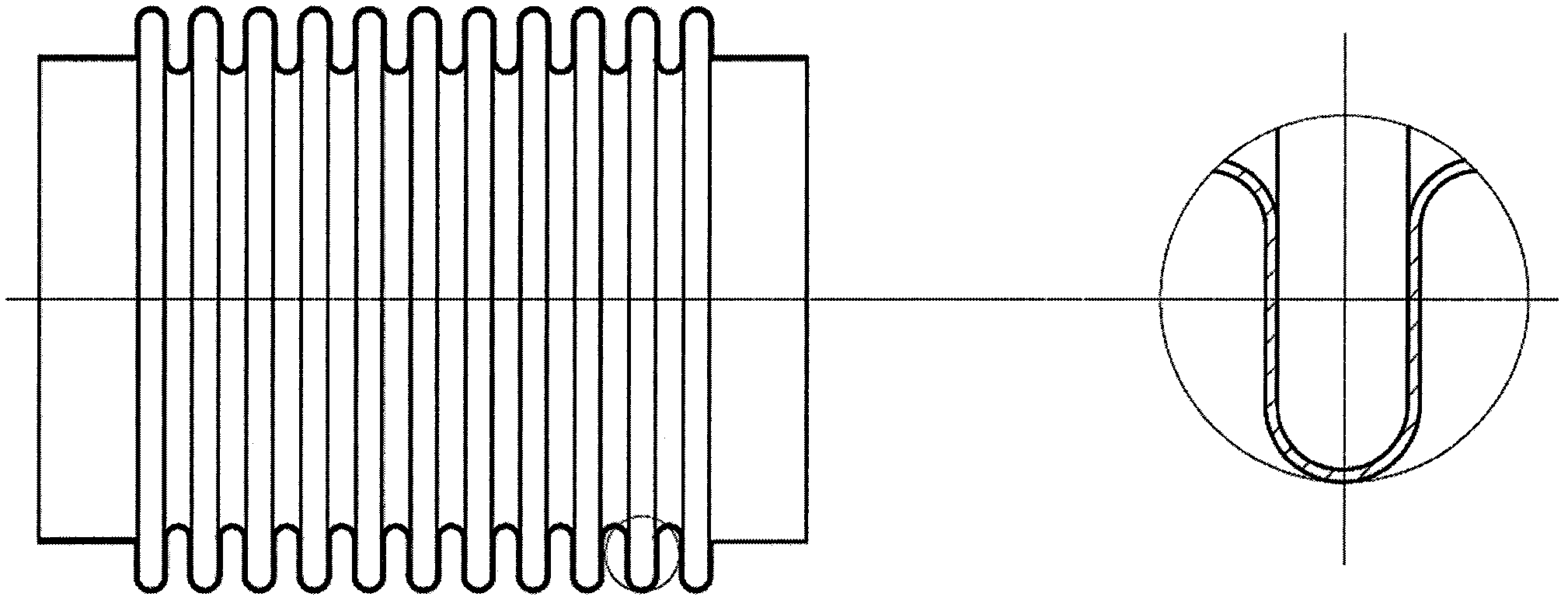

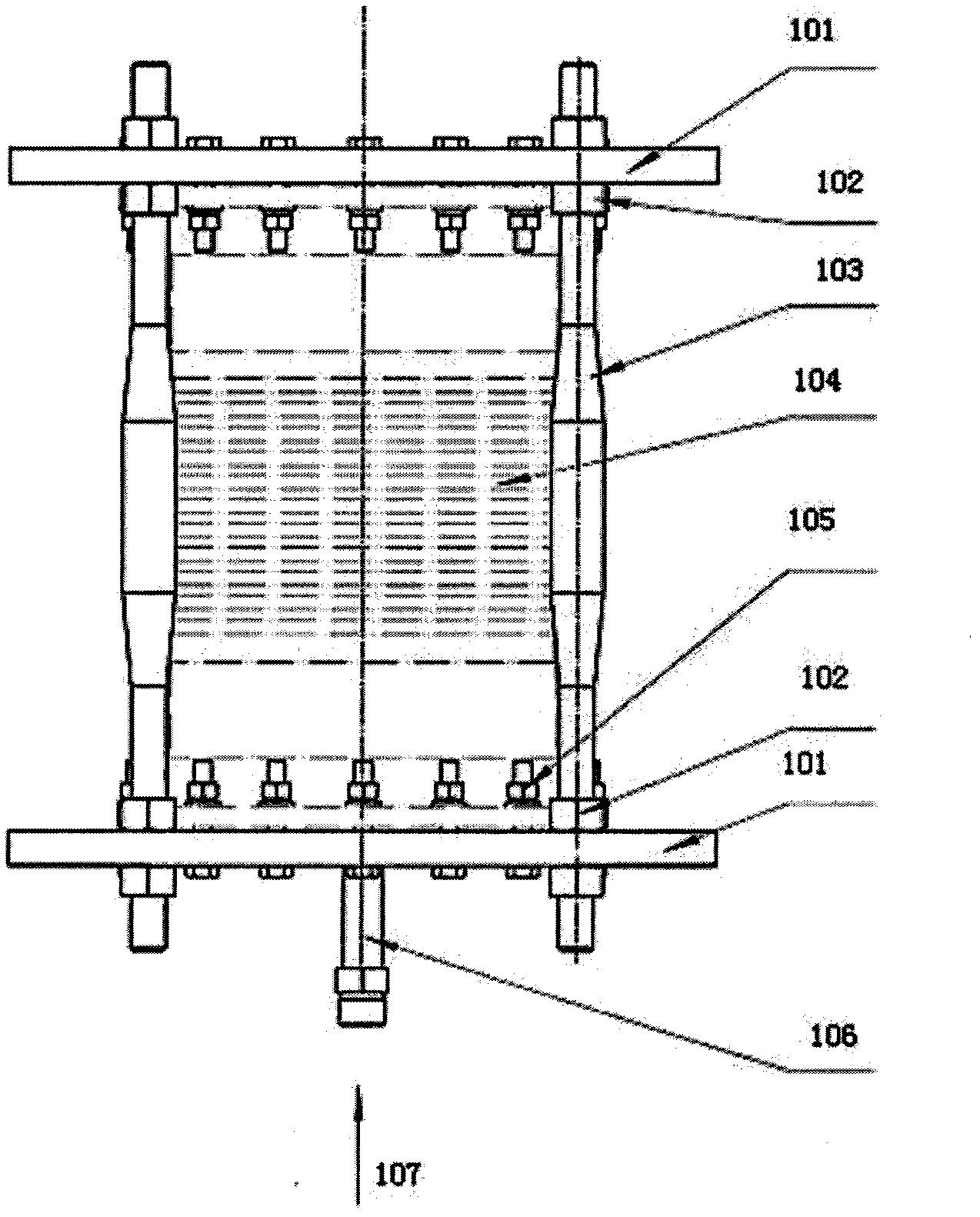

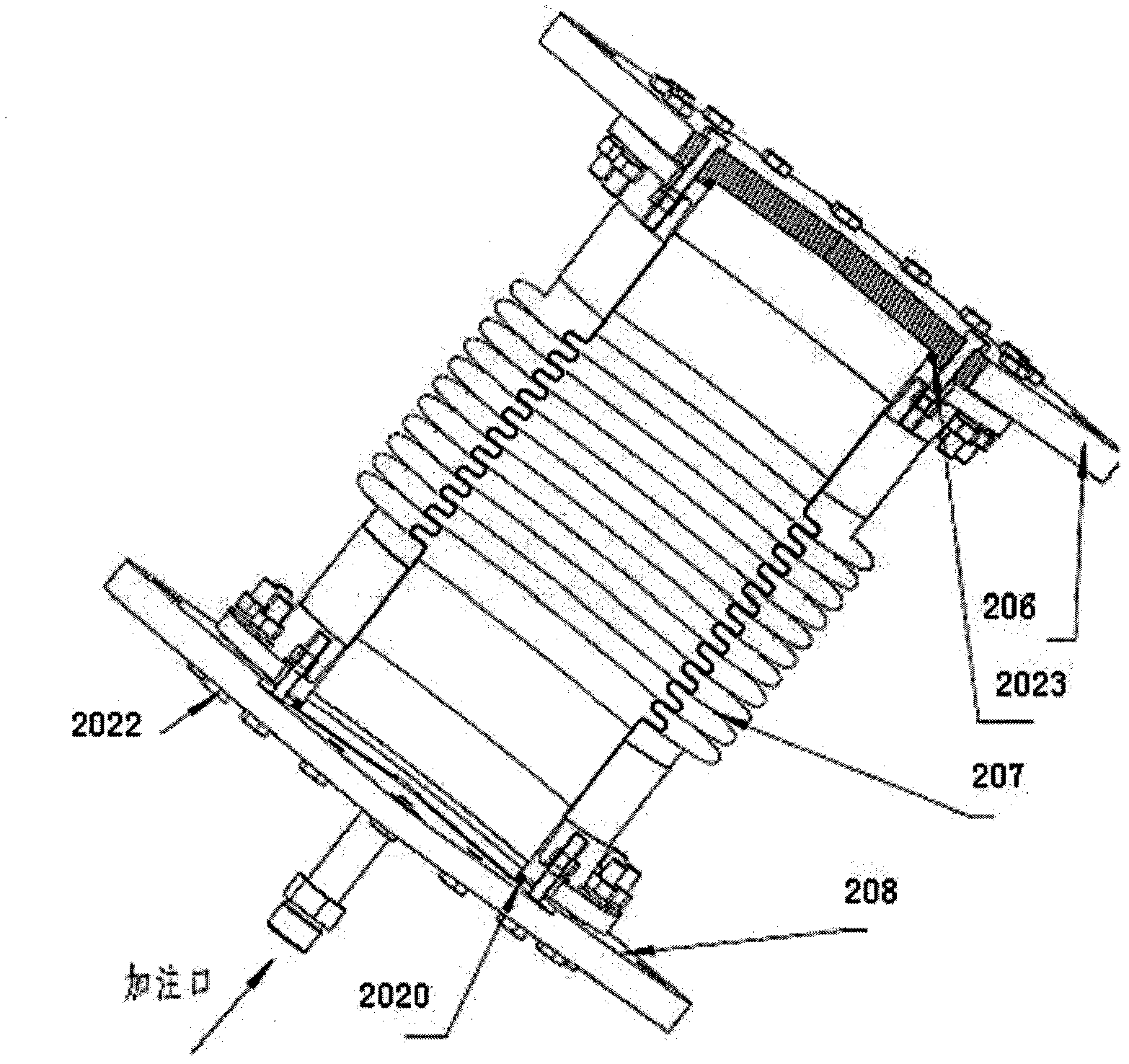

[0023] The structure diagram of the preferred embodiment of the present invention is shown in image 3 :

[0024] The upper load-bearing beam 201 and the lower load-bearing beam 2013 are the main load-bearing parts of the device, which bear the axial load generated by the bellows expansion joint 207 in the blasting test; And bolt 2010 is fixed on the column 204.

[0025] like Figure 4 As shown, the blocking cover 206 is connected to the flange of the bellows expansion joint 207 through bolts, and a sealing ring 2023 is placed between the two to realize sealing; disc connection, a sealing ring 2020 is placed between the two to achieve sealing; image 3 As shown, bolts 205 are used to fix the blocking cover 206 on the liftable pressure plate 203; several pressure plates 209 are used to fix the blocking cover 208 with the filling port on the fixing plate 2012; the blocking cover 208 with the filling port has a Threaded interface for pressurized hose 2017 connection.

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com