Array substrate, display module and preparation method for array substrate

An array substrate and substrate technology, applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of low transmittance of metal materials, low aperture ratio of pixel units, and affecting the brightness of liquid crystal displays, etc., to improve brightness and increase The effect of aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

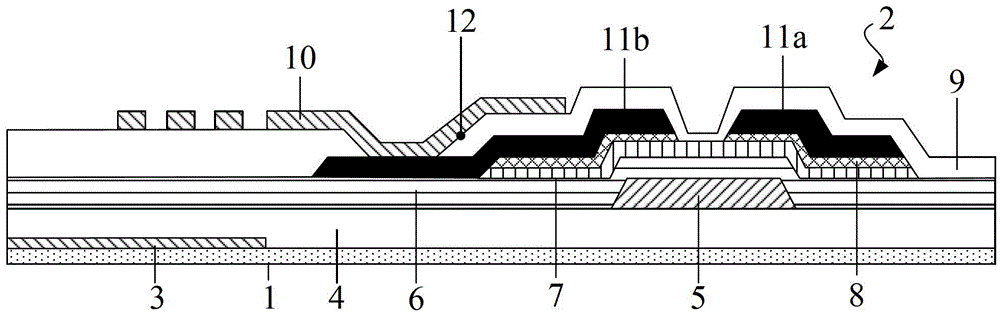

[0024] The invention provides an array substrate, such as figure 1 As shown, including substrate 1, TFT2, gate lines (not shown in the figure) and data lines (not shown in the figure), the gate lines and data lines are surrounded to form a plurality of pixel units, and each pixel unit is formed with a transparent common The electrode 3 and the TFT2 are formed on the transparent common electrode 3 , and an insulating layer 4 is formed between the TFT2 and the transparent common electrode 3 .

[0025] The TFT2 includes: a gate 5 formed on the insulating layer 4; a gate insulating layer 6 covering the gate line, the gate 5 and the insulating layer 4; an active layer 7 corresponding to the gate 5 on the gate insulating layer 6 , ohmic contact layer 8, source electrode 11a, drain electrode 11b, source-drain insulating layer 9 and pixel electrode 10, wherein the material of active layer 7 is amorphous silicon, and the material of ohmic contact layer 8 is amorphous silicon doped with...

Embodiment 2

[0033] In the above-mentioned embodiments, the common electrode lines 13 still need to be provided on the substrate 1 , which makes the formed pattern more complicated, and uses more conductive materials, resulting in waste.

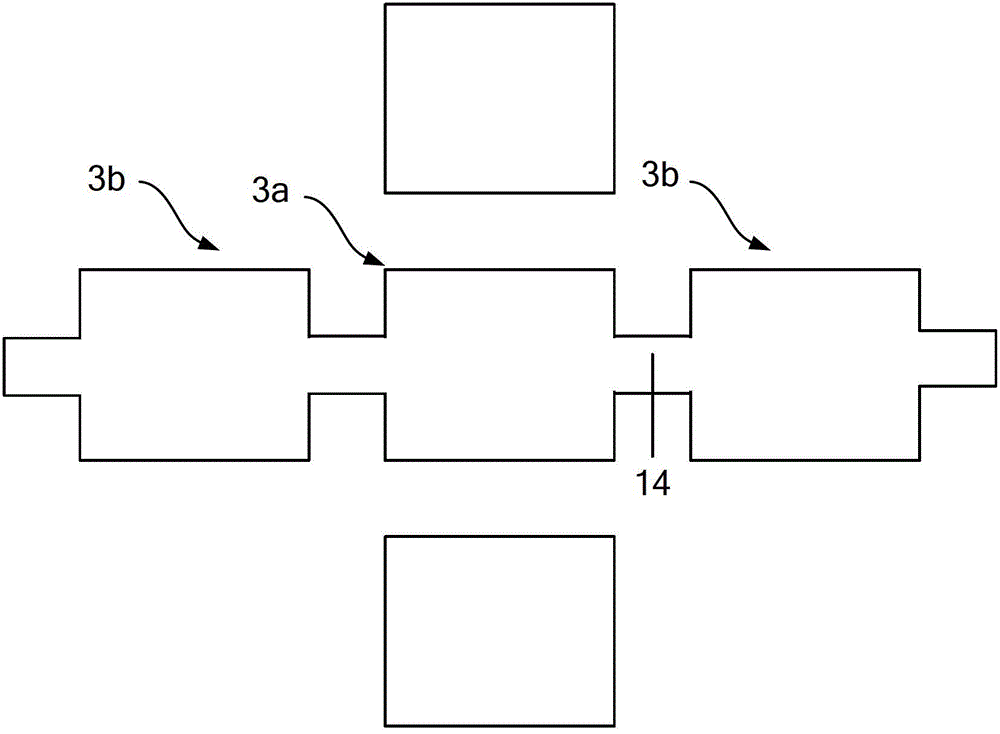

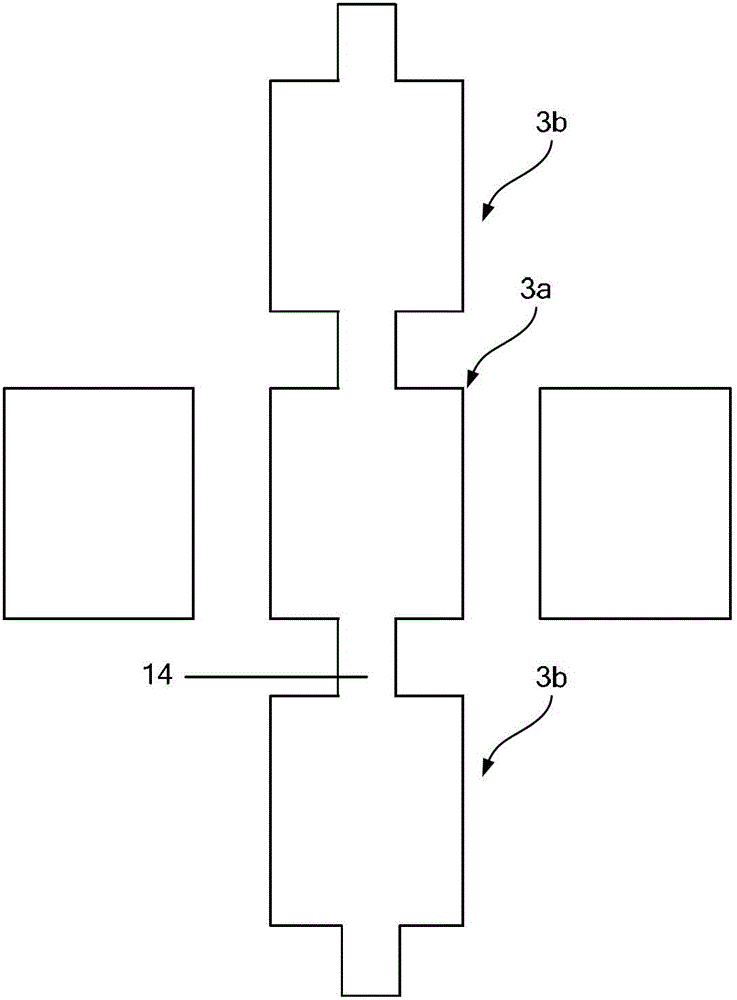

[0034] In order to solve the above problems, preferably, such as figure 2 As shown, the transparent common electrode 3a on the substrate 1 is connected to the transparent common electrode 3b of the adjacent pixel unit through the connection line 14; correspondingly, the common electrode line can only be arranged at the transparent common electrode 3b at the edge of the array substrate; , the control circuit first charges the outermost transparent common electrode through the common electrode line, and the outermost transparent common electrode charges the adjacent transparent common electrode through the connection line 14, so as to charge all the transparent common electrodes 3, and further proceed evenly.

[0035] Specifically, such as figure 2 As ...

Embodiment 3

[0043] Corresponding to the array substrate described in Embodiment 1 and Embodiment 2, the present invention also provides a display module, including the above-mentioned array substrate, the array substrate,

[0044] Such as figure 1 As shown, it includes a substrate 1, TFT2, gate lines and data lines. The gate lines and data lines are surrounded to form a plurality of pixel units, and each pixel unit is formed with a transparent common electrode 3. TFT2 is formed on the transparent common electrode 3. TFT2 and An insulating layer 4 is formed between the transparent common electrodes 3 .

[0045] The TFT2 includes: a gate line and a gate 5 formed on the insulating layer 4; a gate insulating layer 6 covering the gate line, the gate 5 and the insulating layer 4; Source layer 7, ohmic contact layer 8, data line, source electrode 11a, drain electrode 11b, source-drain insulating layer 9 and pixel electrode 10, wherein the material of active layer 7 is amorphous silicon, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com