A test method for simulating loading of an operating mechanism by a simulating loading device

An operating mechanism and loading test technology, applied in simulators, computer control, control using feedback, etc., can solve the problems of being unable to approach the actual change of the resistance torque of the high-voltage switch, unable to detect the reliability of the output torque, and unable to measure the output angle of the mechanism and other problems, to achieve the effect of compact structure, maintenance-free service life and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

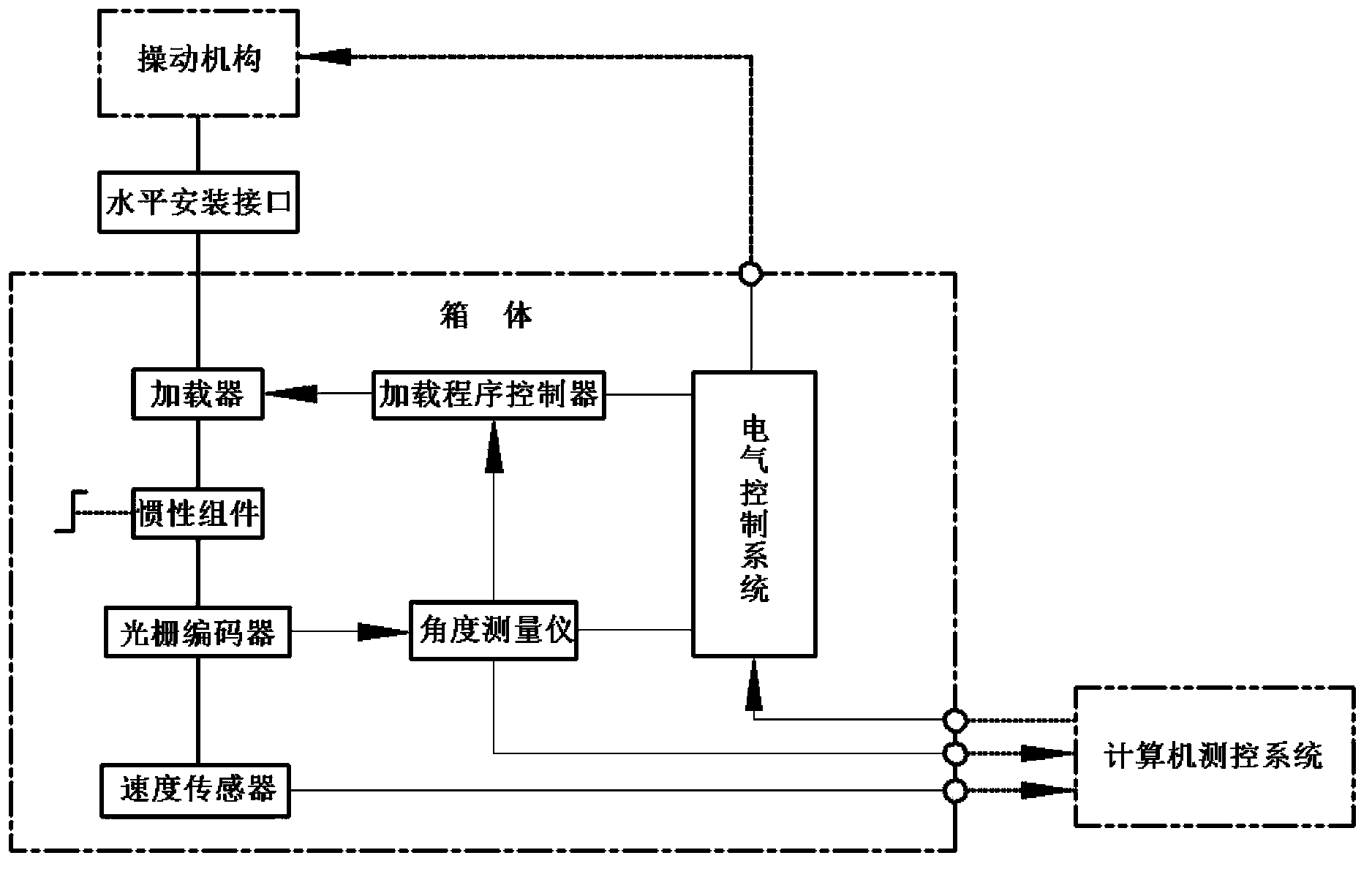

[0032] Such as figure 1 As shown, a simulated loading device includes a box body used to realize the variable loading test of the program control of the operating mechanism; it also includes a docking with the horizontal installation interface, using the setting function of the angle measurement and control instrument in the box to realize For the program-controlled variable loading test of the tested operating mechanism, the computer measurement and control system is used to measure and display the mechanical motion characteristics of the operating mechanism;

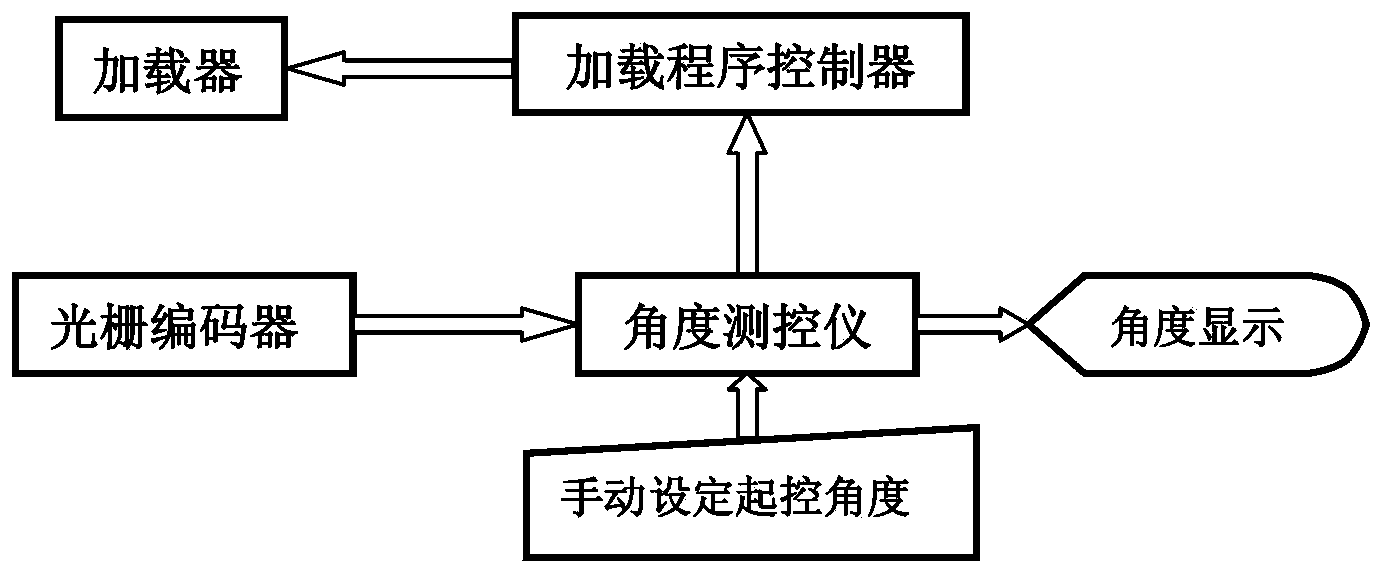

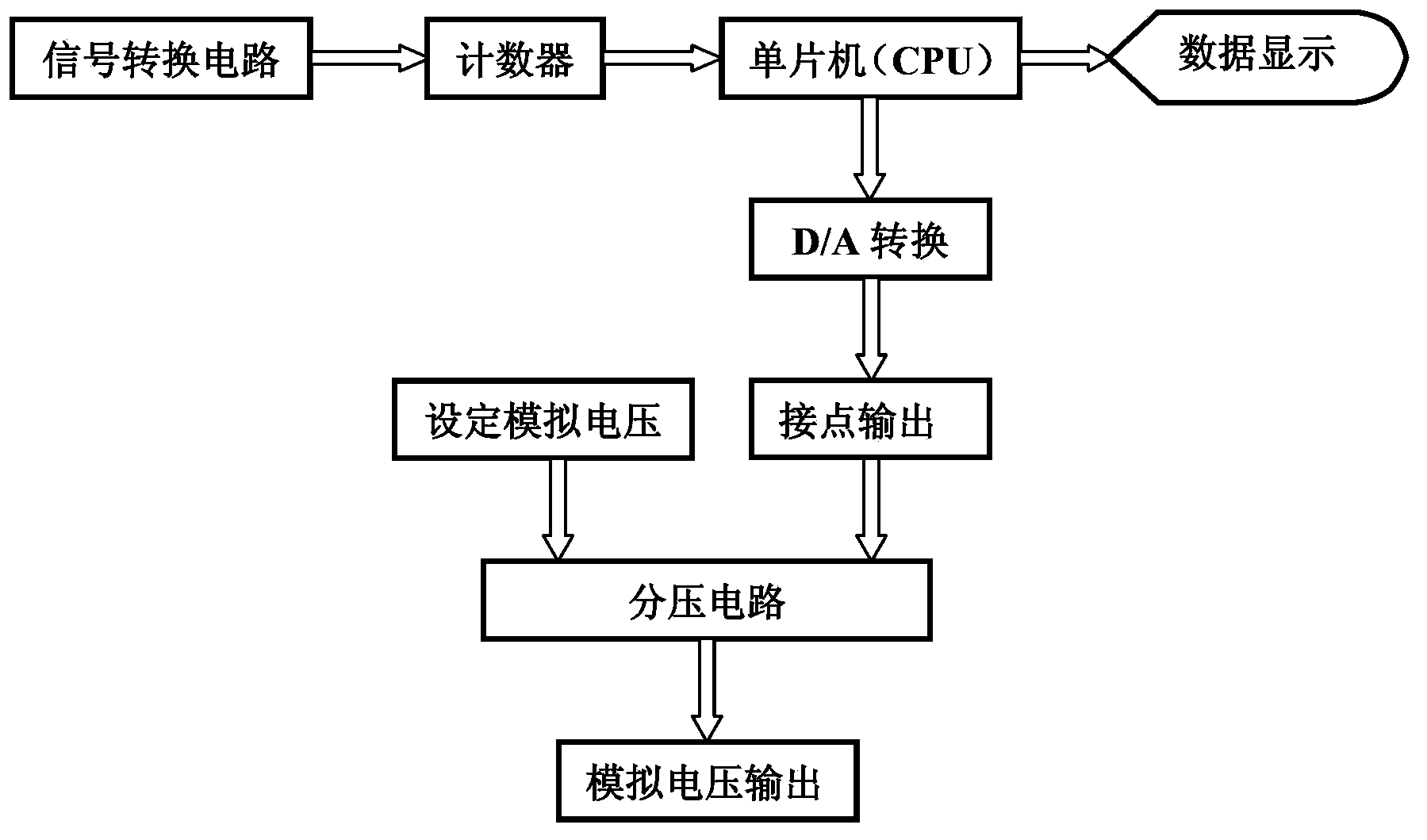

[0033] An electrical control system is installed in the box, and the electrical control system is respectively connected to a loading program controller and an angle measuring and controlling instrument. The loading program controller is connected to a loader, and the angle measuring a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com