Boiler combustion efficiency predicting method based on support vector machine incremental algorithm

A technology of support vector machine and boiler combustion, which is applied in prediction, calculation, computer parts and other directions, and can solve problems such as limited quantity, poor generalization ability, and limited combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

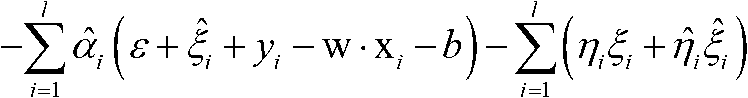

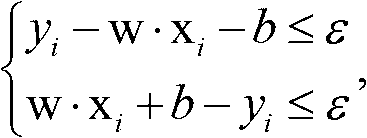

Method used

Image

Examples

Embodiment Construction

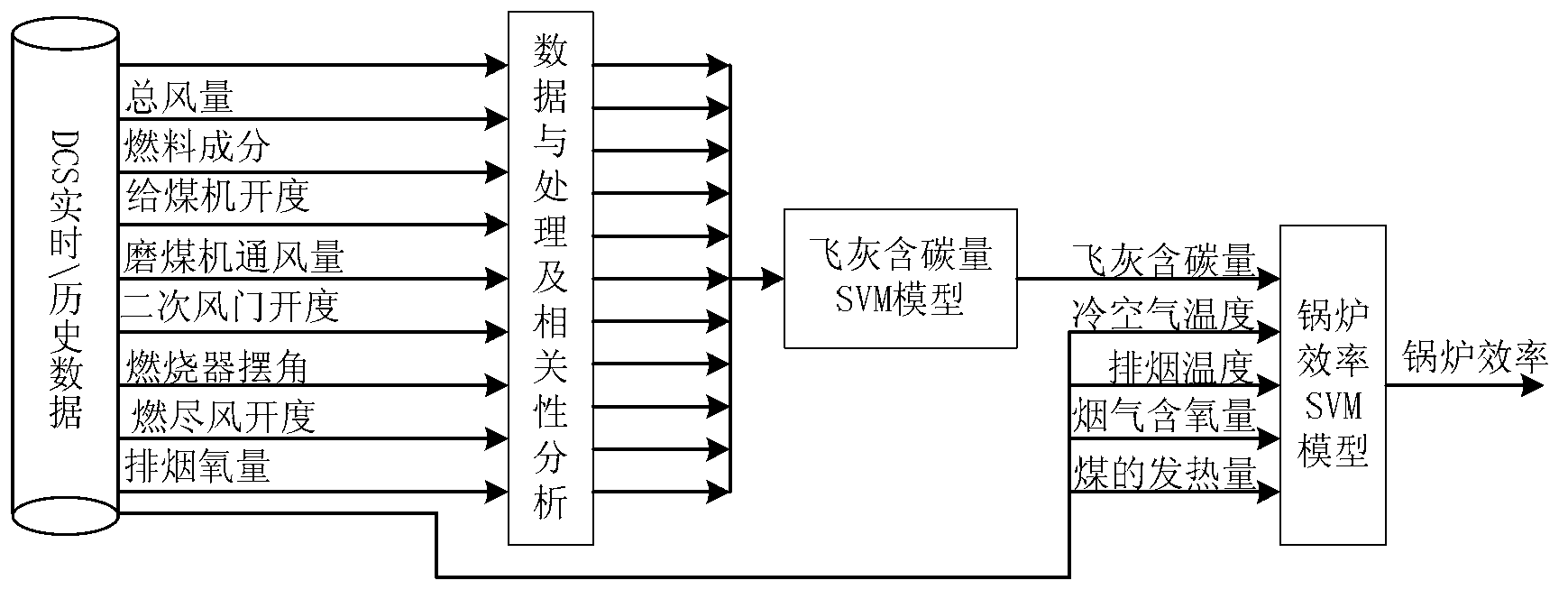

[0054] The following is combined with examples figure 1 The present invention is further described.

[0055] The boiler combustion characteristic model is a special system model. With the change of fuel and external environment, the operating state of the boiler also changes. Training and modeling according to historical data will cause a large error, so this model has a high online training needs. Considering these situations, it is necessary to find a training method that can quickly adjust the training samples to reflect the boiler operating status in time.

[0056] The boiler combustion model in the present invention is simplified to only contain the calculation model of fly ash carbon content, cold air temperature, flue gas oxygen content, flue gas temperature and calorific value of coal, although compared with standard model, simplified model considers The amount of calculation is small and the number of parameters is small, but in actual operation, there is still a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com